Integrated unsealed tank for waste heat recovery of industrial wastewater

A waste heat recovery and industrial waste water technology, applied in the direction of heat exchangers, indirect heat exchangers, cleaning heat transfer devices, etc., can solve the problem of affecting the heat exchange efficiency of the water exchange pipe, occupying the normal production time of the tank, and the sediment is not easy to implement Cleaning and other problems, to achieve the effect of convenient cleaning operation, avoiding the normal production and running time of the tank body, and the linkage structure design is ingenious and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

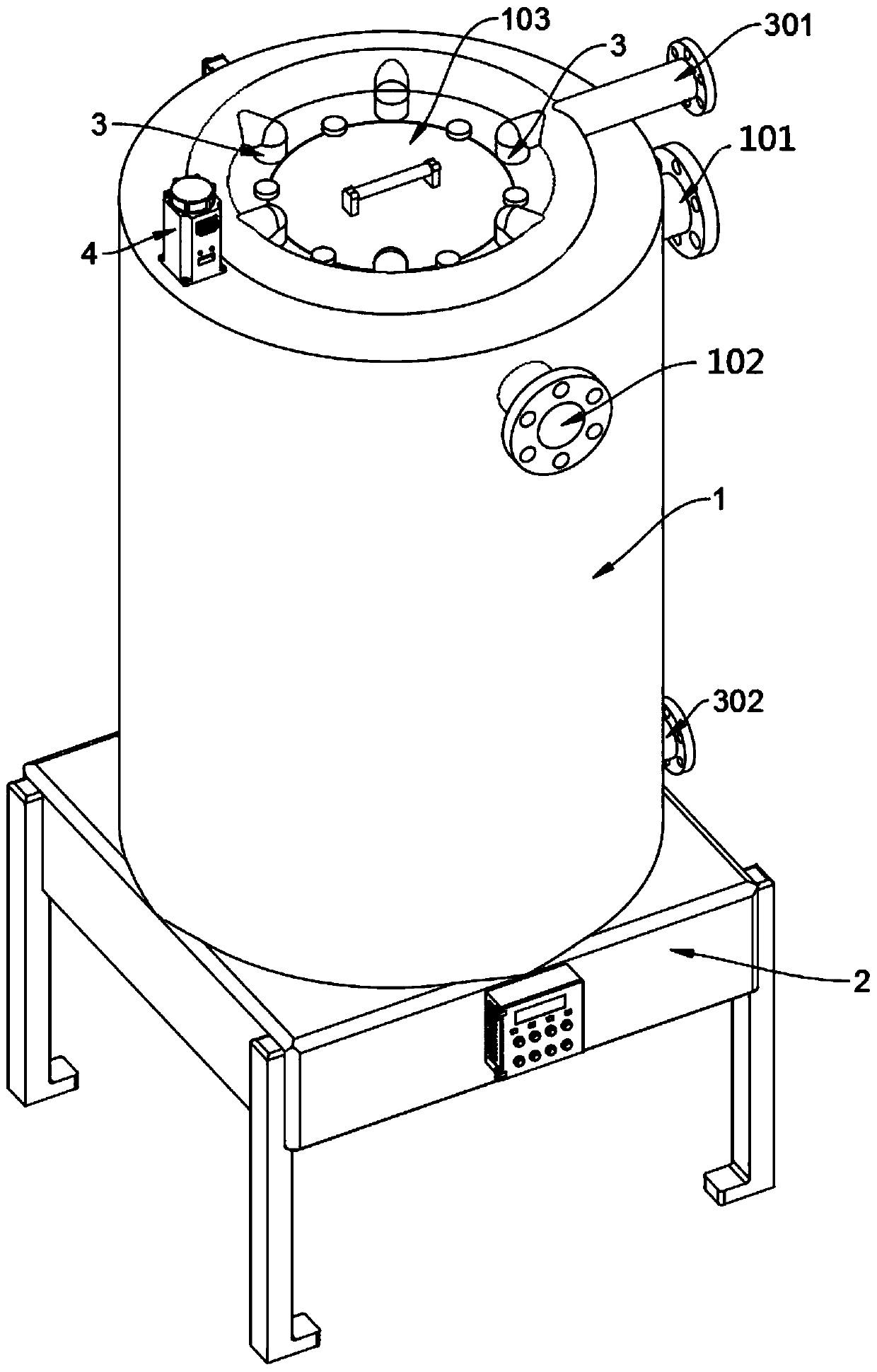

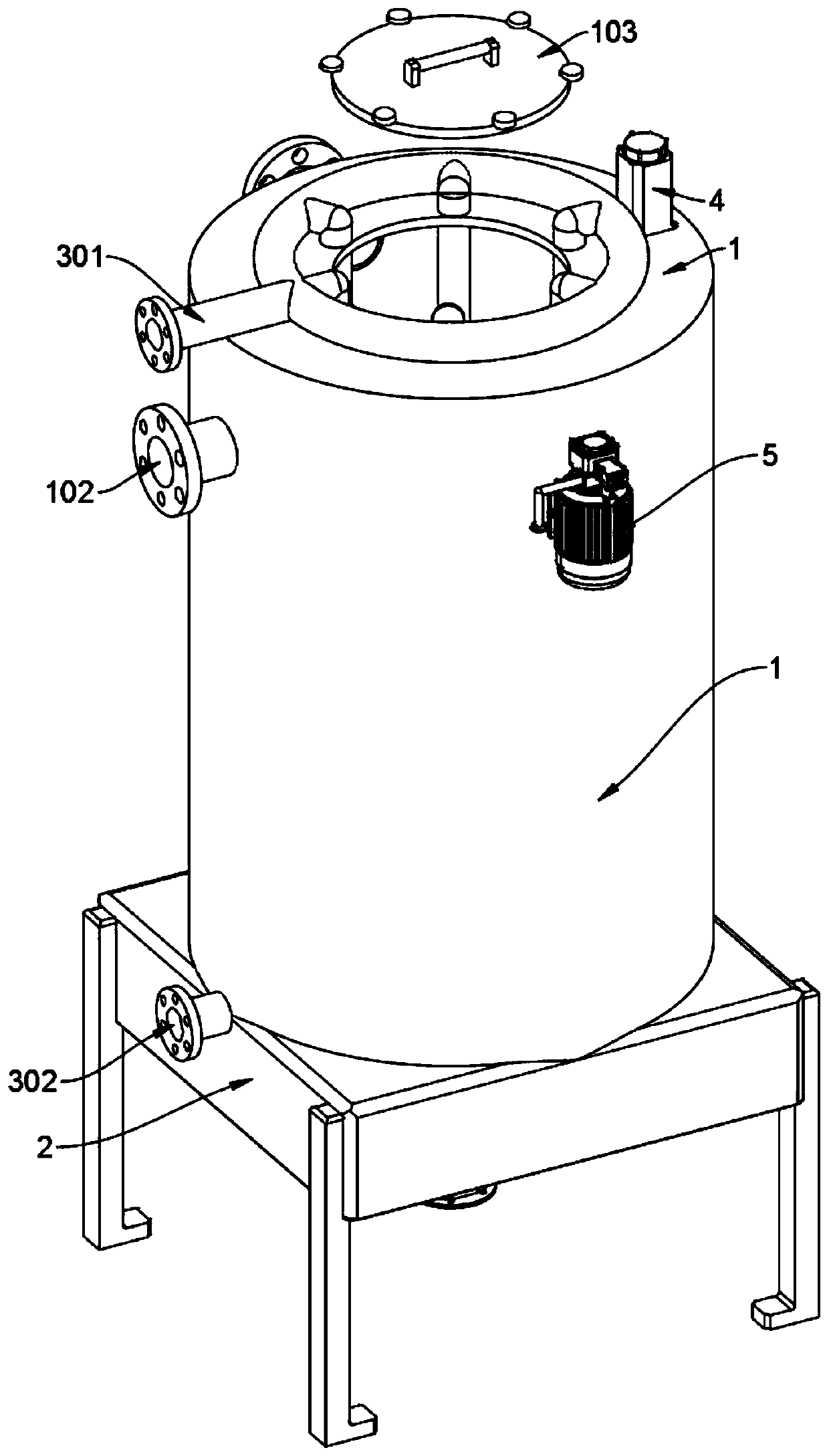

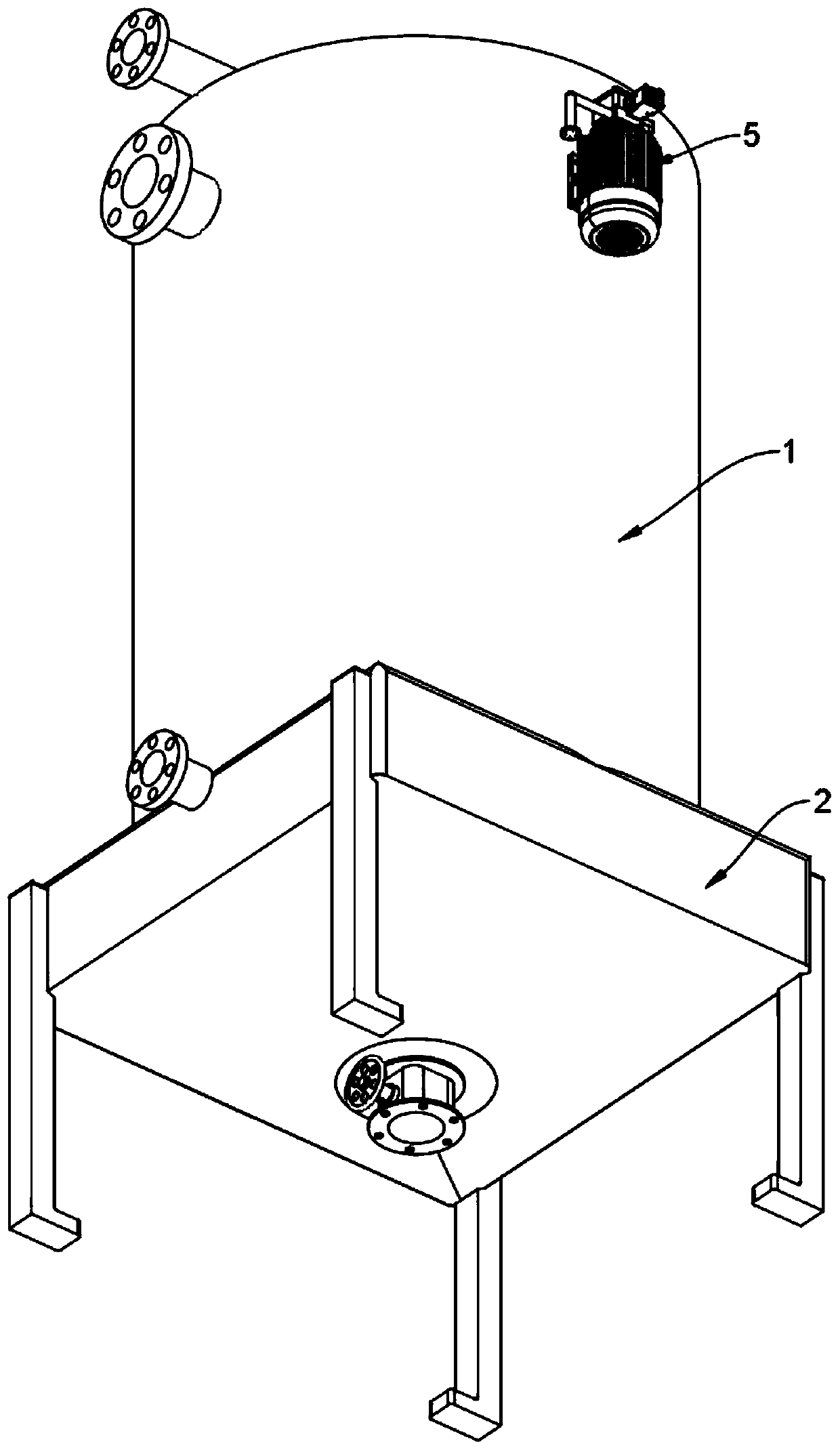

[0036] see Figure 1 to Figure 14 , an embodiment provided by the present invention: an integrated unsealed tank body for waste heat recovery of industrial waste water, comprising a tank body 1, a water spray disc 6 and a supporting brush rod 7, and the tank body 1 includes a waste water inlet pipe 101, the waste water overflow pipe 102 and the tank cover 103, a waste water inlet pipe 101 and a waste water overflow pipe 102 are connected with a waste water inlet pipe 101 and a waste water overflow pipe 102 on the circumferential outer wall of the top position of the tank body 1 at an included angle of 90°, and a waste water overflow pipe 102 is connected. A circular op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com