Urea feeding device, urea feeding method, melamine production device and melamine production method

A technology of feeding device and feeding method, applied in feeding device, chemical instrument and method, organic chemistry and other directions, can solve problems such as loss of ammonia gas and increase of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

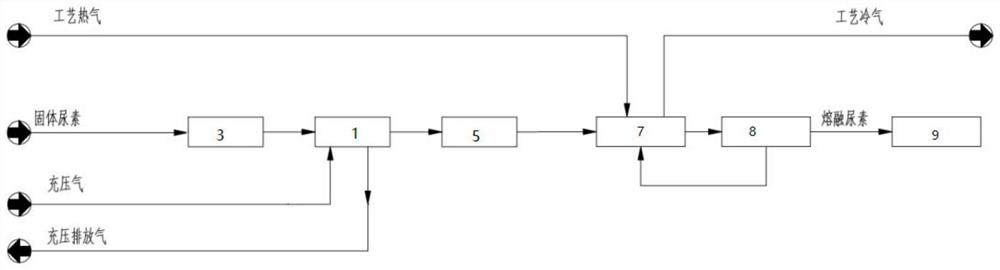

[0055] The present embodiment provides the urea feeding method, adopts such as figure 1 Shown feeding device, concrete steps are as follows:

[0056] Taking the 50,000-ton melamine plant as an example, the melamine produced per hour is 7 tons, and the solid urea raw material consumed is 21 tons. The urea feeding system device mainly includes a first front cut-off valve 3 , a first booster unit 1 , a first rear cut-off valve 5 , a urea washing tower 7 , a urea circulation pump 8 and a reaction unit 9 .

[0057] When feeding, open the first front cut-off valve 3, and send 2 tons of solid urea into the first booster unit 1. Close the first front cut-off valve 3 and the first rear cut-off valve 5, send in the ram gas, after the pressure of the booster unit is increased from normal pressure to 0.4Mpa, stop feeding the booster gas. Open the first cut-off valve 5 to send solid urea into the urea washing tower 7. The urea circulation volume is 1000m 3 / h, after the solid urea dire...

Embodiment 2

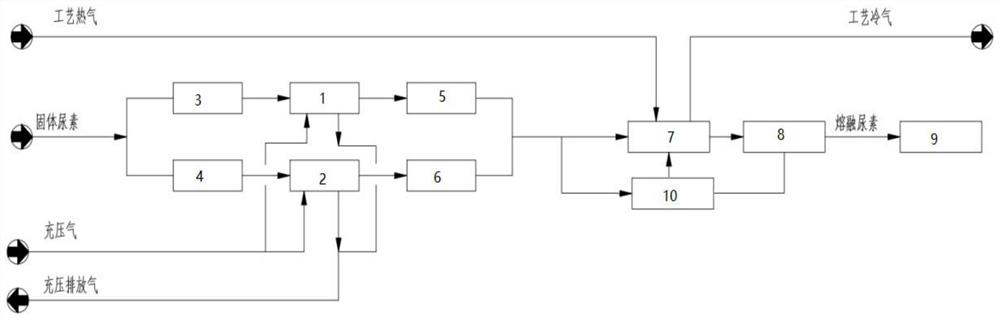

[0061] The present embodiment provides the urea feeding method, adopts such as figure 2 Shown feeding device, concrete steps are as follows:

[0062] Taking the 100,000-ton melamine plant as an example, the melamine produced per hour is 14 tons, and the solid urea raw material consumed is 42 tons. The urea feeding device mainly includes a first front cut-off valve 3 , a first booster unit 1 , a first rear cut-off valve 5 , a urea washing tower 7 , a urea circulating pump 8 , a reaction unit 9 and a premixing unit 10 .

[0063] When feeding, open the first front cut-off valve 3, and send 4 tons of solid urea into the first booster unit 1. Close the first front cut-off valve 3 and the first rear cut-off valve 5, send in the ram gas, after the pressure of the first boost unit 1 is increased from normal pressure to 0.8Mpa, stop feeding the boost gas. Open the first post-cut-off valve 5 to send the solid urea and liquid urea from the urea circulation pump to the urea washing tow...

Embodiment 3

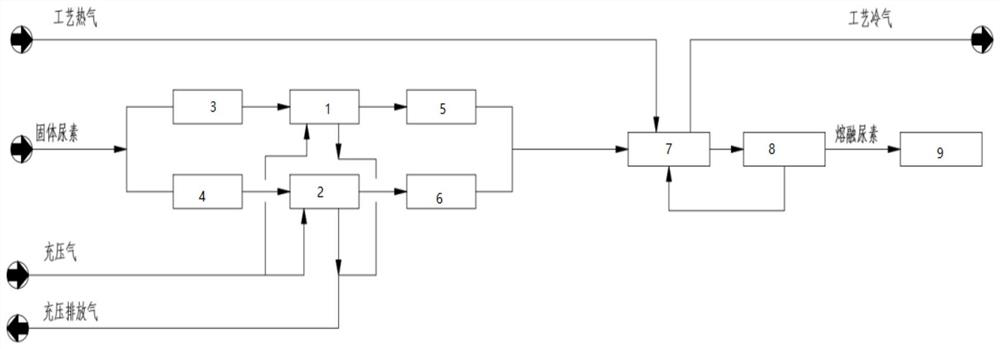

[0069] The present embodiment provides the urea feeding method, adopts such as image 3 Shown feeding device, concrete steps are as follows:

[0070] Taking the 100,000-ton melamine plant as an example, the melamine produced per hour is 14 tons, and the solid urea raw material consumed is 42 tons. The urea feeding device mainly includes a first front cut-off valve 3 , a first booster unit 1 , a first rear cut-off valve 5 , a urea washing tower 7 , a urea circulating pump 8 , a reaction unit 9 and a premixing unit 10 .

[0071] When feeding, open the first front cut-off valve 3, and send 4 tons of solid urea into the first booster unit 1. Close the first front cut-off valve 3 and the first rear cut-off valve 5, send in the ram gas, after the pressure of the first boost unit 1 is increased from normal pressure to 1.0Mpa, stop feeding the boost gas. Open the first post-cut-off valve 5 to send the solid urea and liquid urea from the urea circulation pump to the urea washing towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com