Porous carbon material based on eupatorium adenophorum as well as preparation method and application of porous carbon material

A porous carbon material, Eupatorium adenophorum technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of environmental protection and preparation difficulties, and achieve good removal effect, The environmental protection effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

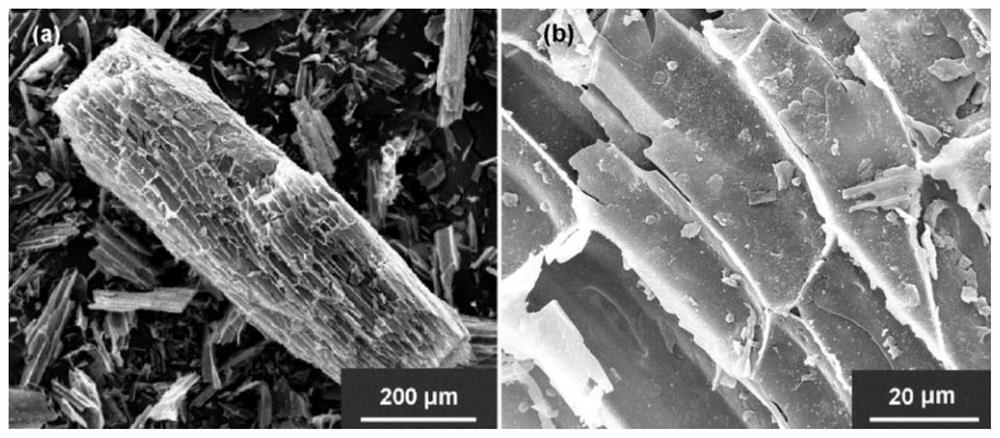

[0028] Embodiment 1: A preparation method based on Eupatorium adenophorum porous carbon material, the steps are as follows:

[0029] Cut the stem of Eupatorium adenophorum into inch-long sections, wash and remove dust, then soak in 5wt% HCl solution for 2 days and then wash with distilled water to remove HCl; after drying in an oven at 90 ° C, place in a tube furnace, Under the atmosphere, the temperature was raised to 350° C. at a rate of 5° C. / min and heated for 2 hours, and then the temperature was raised to 900° C. for carbonization for 5 hours to obtain the porous carbon material based on Eupatorium adenophorum.

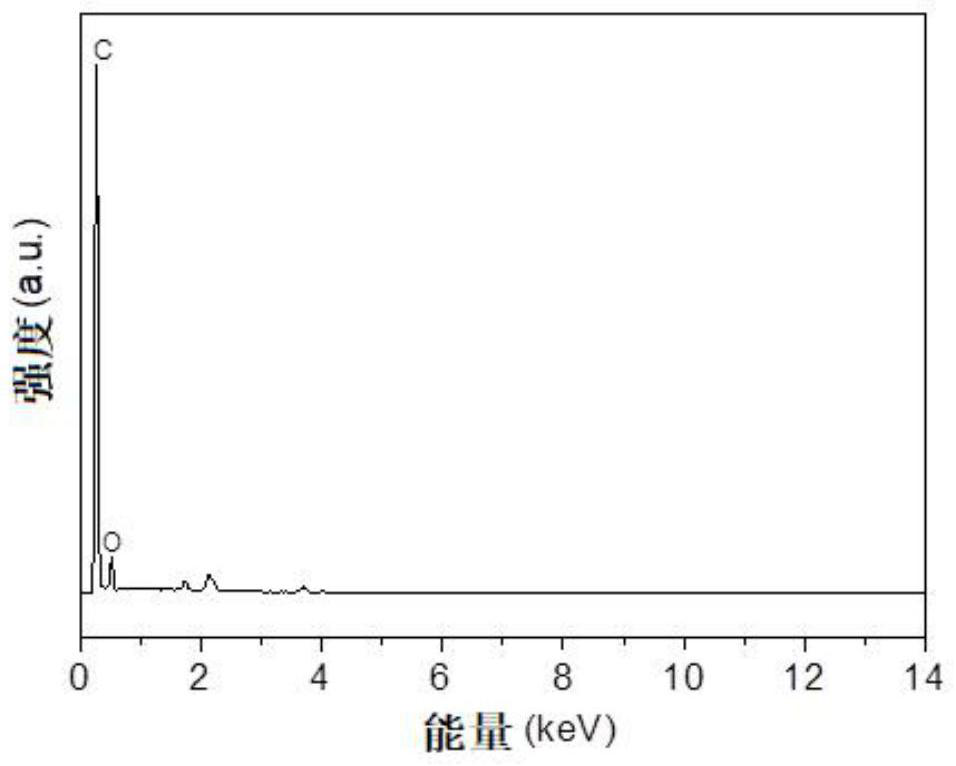

[0030] figure 1 It is the EDS diagram of the prepared porous carbon material. Depend on figure 1 It can be seen that the prepared porous carbon material only contains C and O elements, and does not contain other impurity elements. It shows that the small amount of metal elements inherent in the stem of Eupatorium bauhinia has been eluted by HCl solution, and ...

Embodiment 2

[0033] Example 2: The Eupatorium adenophorum-based porous carbon material prepared in Example 1 was used for the adsorption of phenol in water.

[0034] Select an aqueous solution with an initial concentration of phenol of 100mg / L, change the amount of porous carbon material to 0.2-0.7g / L, and adsorb for 12 hours to investigate the adsorption of phenol by the amount of adsorbent; the effect of the amount of adsorbent by porous carbon material on adsorption is as follows Figure 4 shown. From Figure 4It can be clearly seen that with the increase of the amount of porous carbon material adsorbent, the adsorption rate of phenol increases, and the adsorption rate reaches the maximum when the amount of porous carbon material adsorbent is equal to 0.5g / L, and then the adsorption tends to balance. However, the adsorption amount of phenol showed a significant downward trend with the increase of the amount of porous carbon material adsorbent. This is because the increase in the amount...

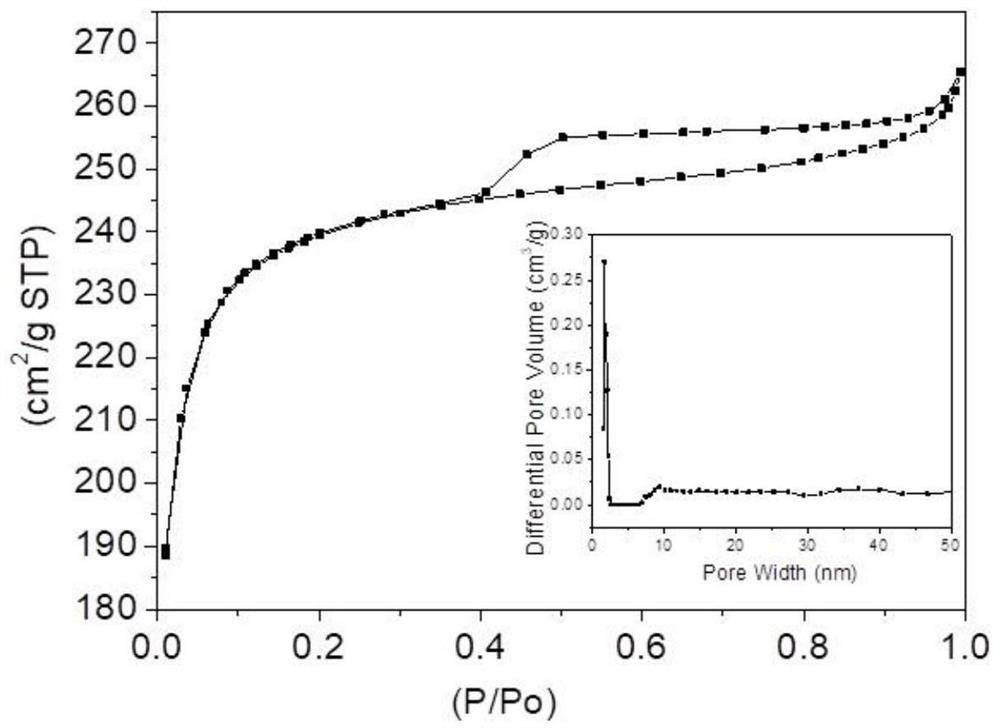

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com