Open-loop expanding machine suitable for flat conducting bar

An open-loop, expanding machine technology, used in storage devices, metal processing equipment, feeding devices, etc., can solve the problem of batch errors in bar bending accuracy, lack of automatic bending devices and controls, and bar ends. To solve the problem of large difference in the radian of the part, it can achieve the effect of ingenious structure, low slot full rate and good excitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

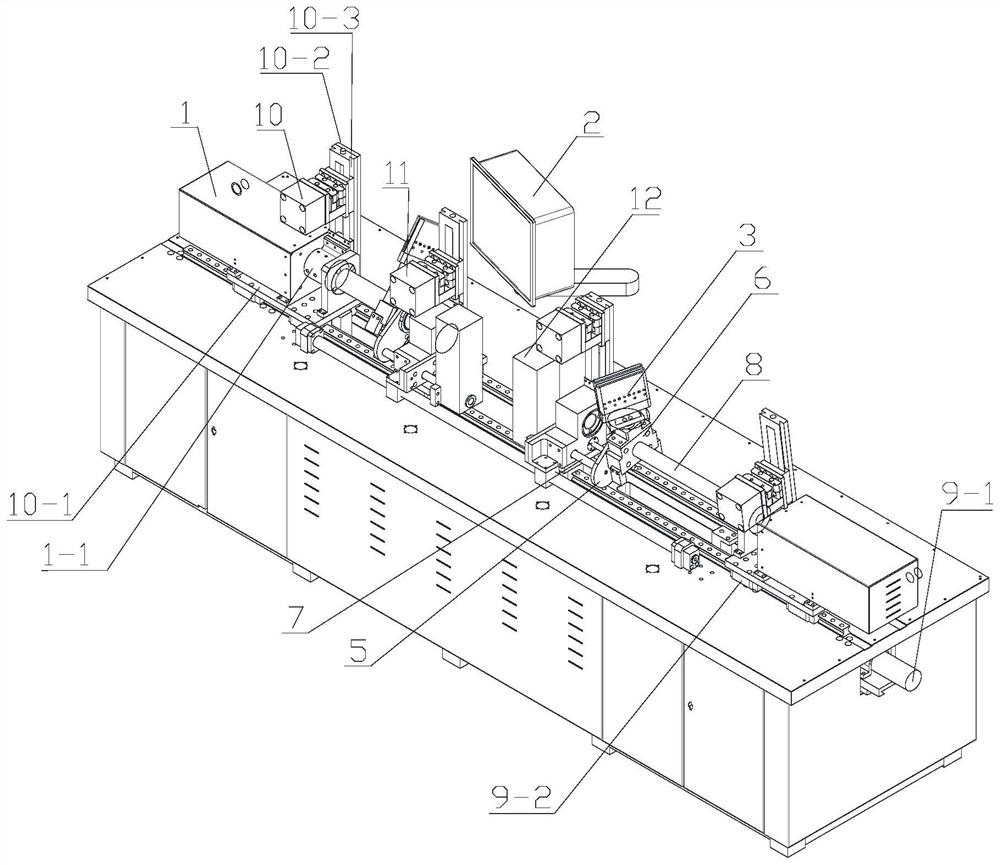

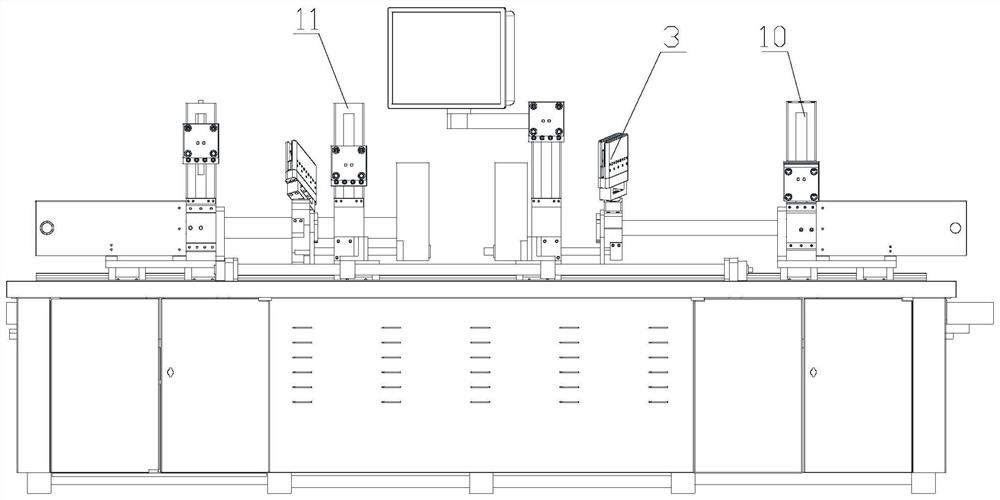

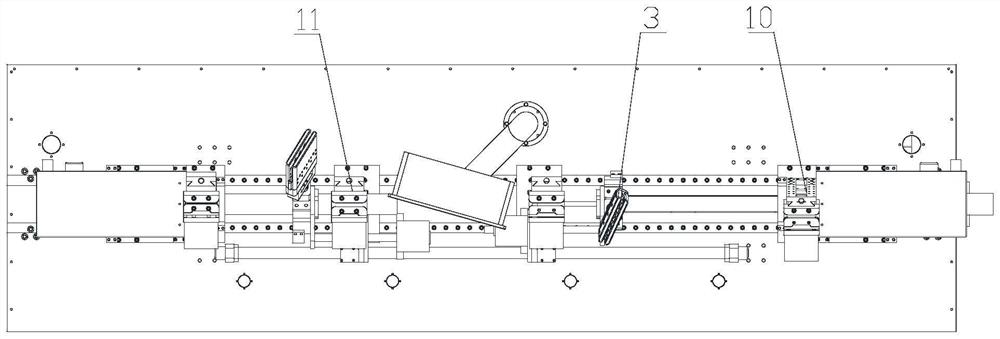

[0036] See Figure 1 to Figure 6 , the open-loop stretching machine adapted to flat guide bars in this embodiment includes a first clamping device 11, a second clamping device 10, and a radian clamping device 3 for placing workpieces, and the radian clamping device Located between the first clamping device and the second clamping device, it also includes a central shaft 8, a left and right rotation power mechanism 1, a radian plate stabilization motor 12, a reverse pull-in mechanism and a control center 2. The first clamp The clamping device, the second clamping device, and the radian clamping device are all arranged at the axis position of the central shaft, and the second clamping device rotates concentrically around the central shaft under the drive of the left and right rotating power mechanism to move The inner side moves, and the second clamping device limits the moving speed of the inner side under the reverse pulling force of the reverse pull-in mechanism. The expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com