Rapid tool setting method for numerical control machining tool

A technology for machining tools and tools, applied in the field of rapid tool setting of CNC machining tools, can solve the problems of low tool setting accuracy and tool wear, and achieve the effects of good versatility, low manufacturing cost, and high tool setting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution in this application, the technical solution for realizing the purpose of the invention of the application will be further described below through several specific examples. It should be noted that the technology claimed in this application Protocols include, but are not limited to, the following examples. Based on the embodiments in this application, all other embodiments obtained by those skilled in the art without creative efforts shall fall within the protection scope of this application.

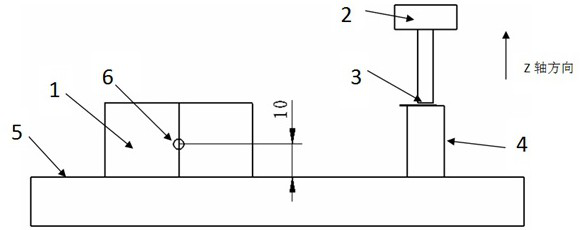

[0024] At present, in the prior art, tool setting by trial cutting method and tool setting by tool setting block are commonly used tool setting methods. Among them, the trial cutting method is simple and convenient for tool setting, but it will cause certain wear and tear on the tool during the trial cutting process, and the accuracy of tool setting is relatively low, while the tool setting met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com