Automatic lubricating system for movable blade and fixed blade of push shear head

An automatic lubricating and moving blade technology, applied in the field of beauty and hairdressing appliances, can solve the problems of weakened blade sharpness, unreasonable structural design, weakened shear performance, etc., so as to avoid sharpness and life reduction, improve convenience, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

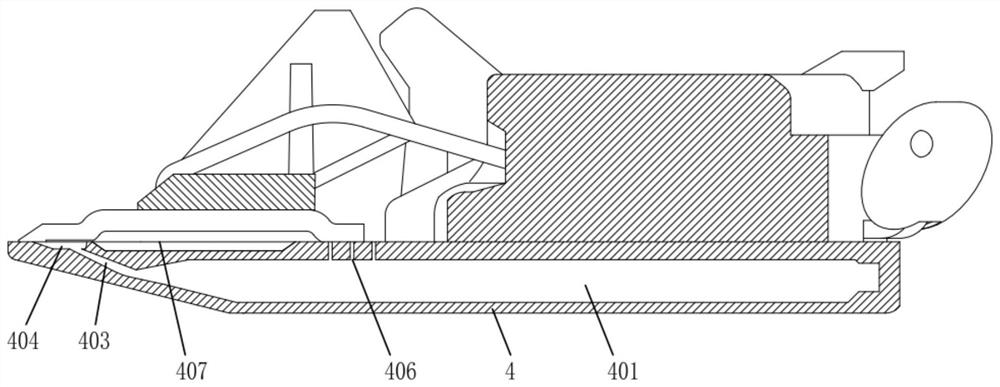

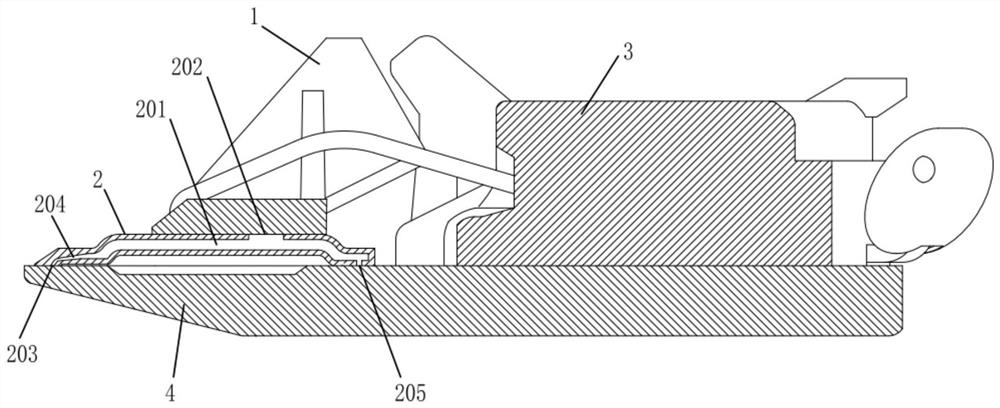

[0041] like figure 1 and figure 2 As shown, an automatic lubricating system for a movable blade and a fixed blade for pushing a scissor head provided by the present invention includes a fixed blade 4 with a first oil storage cavity 401 inside, a second oil storage cavity 201 inside a fixed blade 4 For the movable blade 2, the teeth of the movable blade 2 are located above the teeth of the fixed blade 4, and the movable blade 2 and the fixed blade 4 can reciprocate relative to each other. A first oil storage structure is formed on the side of the interdental edge surface of the fixed blade 4 close to the movable blade 2 , the first oil storage structure is communicated with the first oil storage cavity 401 , and the interdental edge surface of the movable blade 2 is close to the fixed blade 4 A second oil storage structure 203 is formed on one side of the device, and the second oil storage structure 203 communicates with the second oil storage cavity 201 .

[0042] The greas...

Embodiment 2

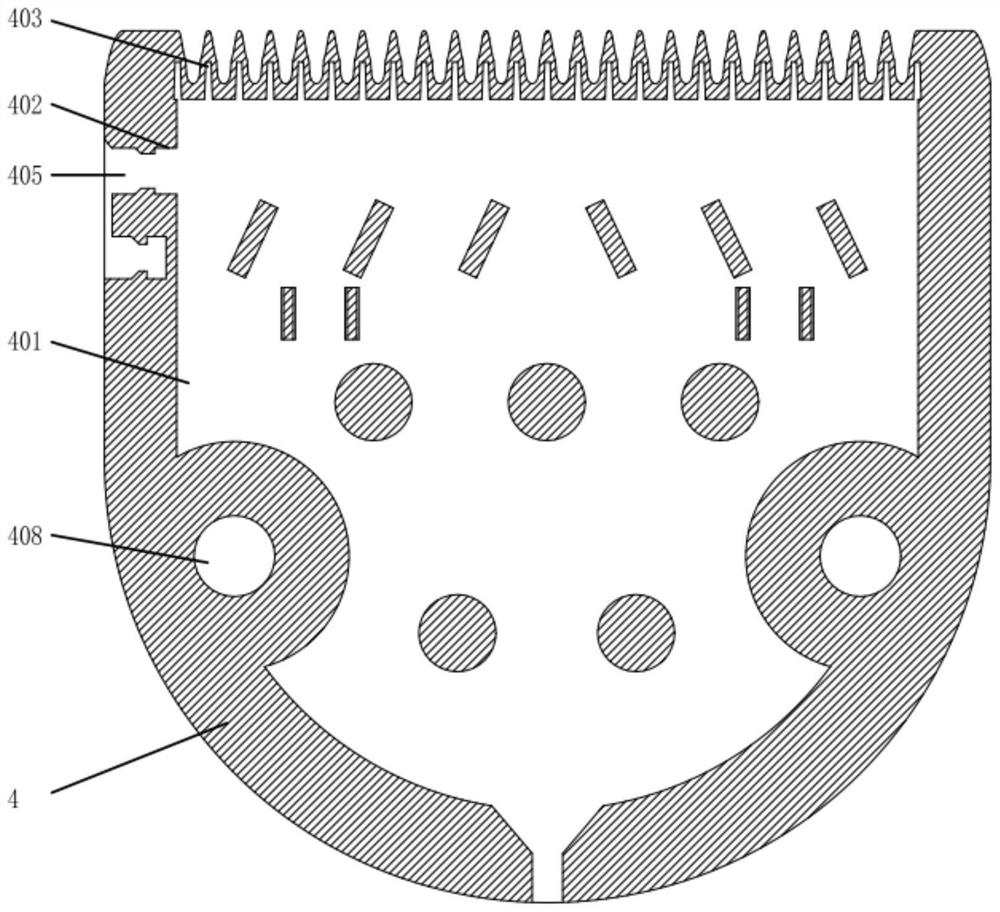

[0056] like image 3 and Figure 4 As shown, based on Embodiment 1, according to an automatic lubricating system for a movable blade and a fixed blade for pushing a scissor head provided by the present invention, one end of the fixed blade 4 is formed with a tooth portion, and the open port of the oil storage tank 404 is located at the end of the tooth portion. upper surface. The first oil filling port 402 is formed on the side wall of the stationary blade 4 , and the position of the first oil filling port 402 can be set according to the size of the first oil storage cavity 401 . 401 is filled with grease, so that the user can quickly add grease to the pushing scissors head, and the long-term supply of grease can be ensured after one-time grease addition, and there is no need to add grease to the movable blade 2 and the fixed blade 4 during use. The first oil filling port 402 is fitted with a first plug 405 for closing or opening the first oil filling port 402 to avoid leaka...

Embodiment 3

[0065] like figure 1 and figure 2 As shown, based on Embodiment 2, a push scissor head provided according to the present invention further includes a spring assembly, a blade support 3 and a guide block 1, and the spring assembly, the blade support 3 and the guide block 1 are all installed on the fixed On the upper surface of the blade 4, the tooth end of the movable blade 2 is located above the tooth end of the fixed blade 4, and the spring assembly is used to drive the movable blade 2 to move relative to the fixed blade 4, and the guide block 1 and the blade support 3 are used to limit the movable blade. 2 movements.

[0066] working principle

[0067] Before using the scissor head, open the first plug 405, and add grease to the first oil storage cavity 401 through the first oil filling port 402. After filling, use the plug 405 to close the oil filling port 402 and open the second plug. Add grease to the second oil storage cavity 201 through the second oil filling port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com