Casting machine for cast film processing

A casting machine and casting film technology, applied in the field of casting machines, can solve the problems of prolonged standby time of casting machines, inconvenient disassembly for replacement, and heavy quality, so as to ensure the continuity of operation and reduce the downtime of equipment , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiment of the application discloses a casting machine for casting film processing.

[0036] The following is attached Figure 1-5 The application is described in further detail.

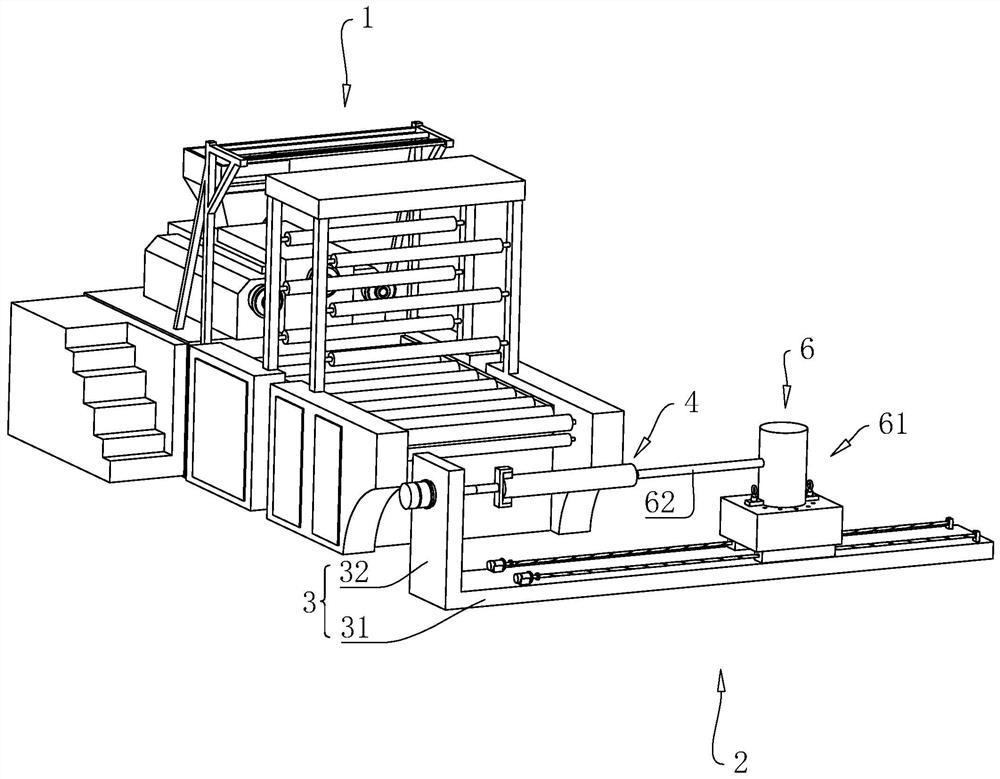

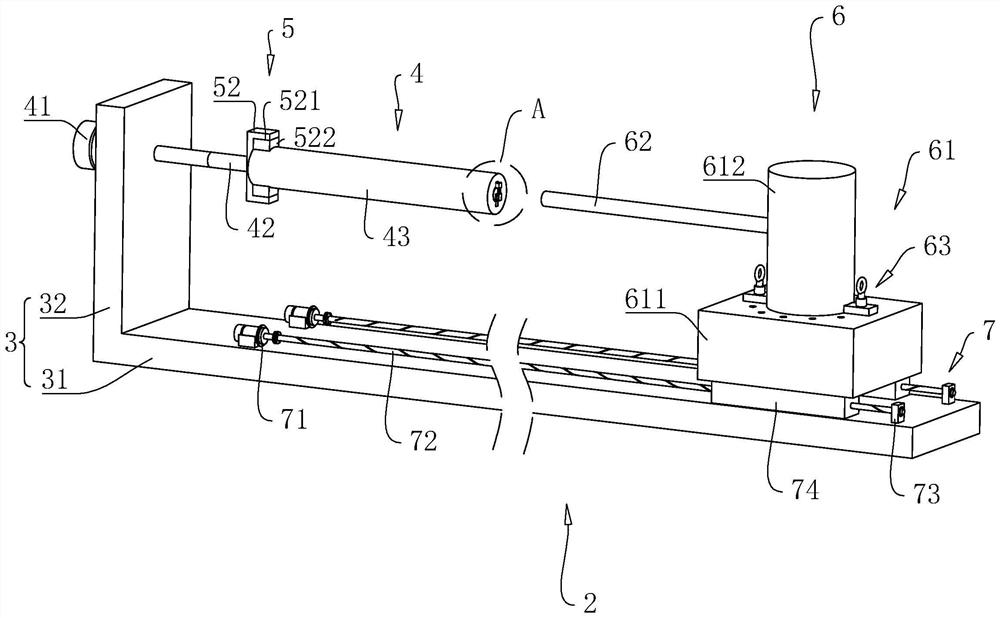

[0037] refer to figure 1 , The tape casting machine includes a machine body 1 and a winding device 2 . The winding device 2 is arranged on the ground and is located at one end of the machine body 1 in the longitudinal direction. The cast film processed and formed by the machine body 1 is wound up by the winding device 2 .

[0038] refer to figure 1 , The winding device 2 includes a fixed frame 3 and a winding mechanism 4 , wherein the fixed frame 3 includes a horizontal plate 31 and a vertical plate 32 . The horizontal plate 31 is fixed on the ground by bolts, and the vertical plate 32 is welded on the horizontal plate 31 along the vertical direction, and the vertical section of the vertical plate 32 and the horizontal plate 31 is L-shaped.

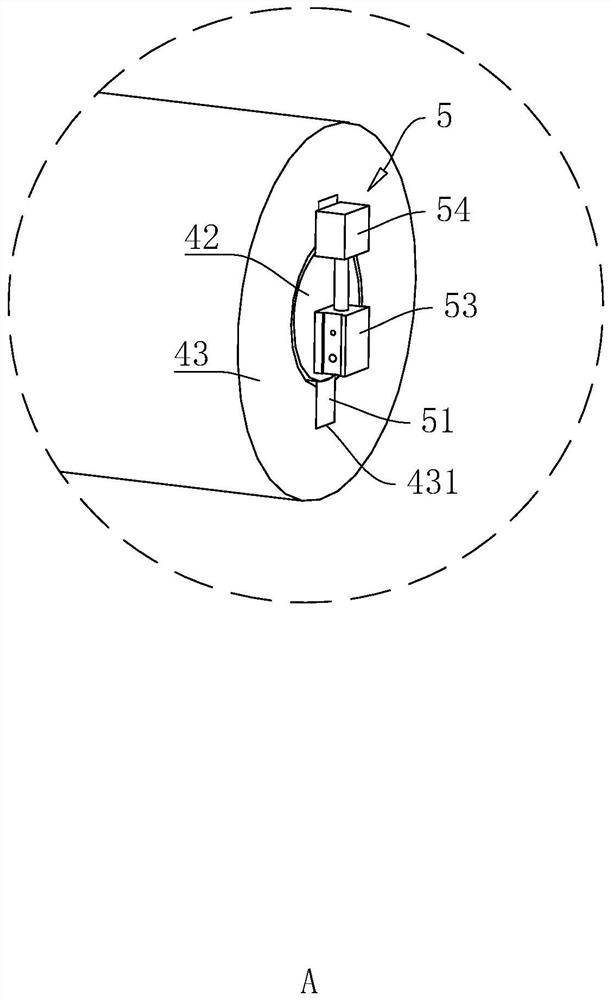

[0039] refer to figure 2 , the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com