Reversible anti-smashing device with remote control and automatic induction functions

An automatic sensing and remote control technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of occupying the site, the height of the anti-smashing shed, the height of the vehicle, the width limit, and the inability to meet the safety requirements of the hanging basket. To achieve the effect of convenient operation and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

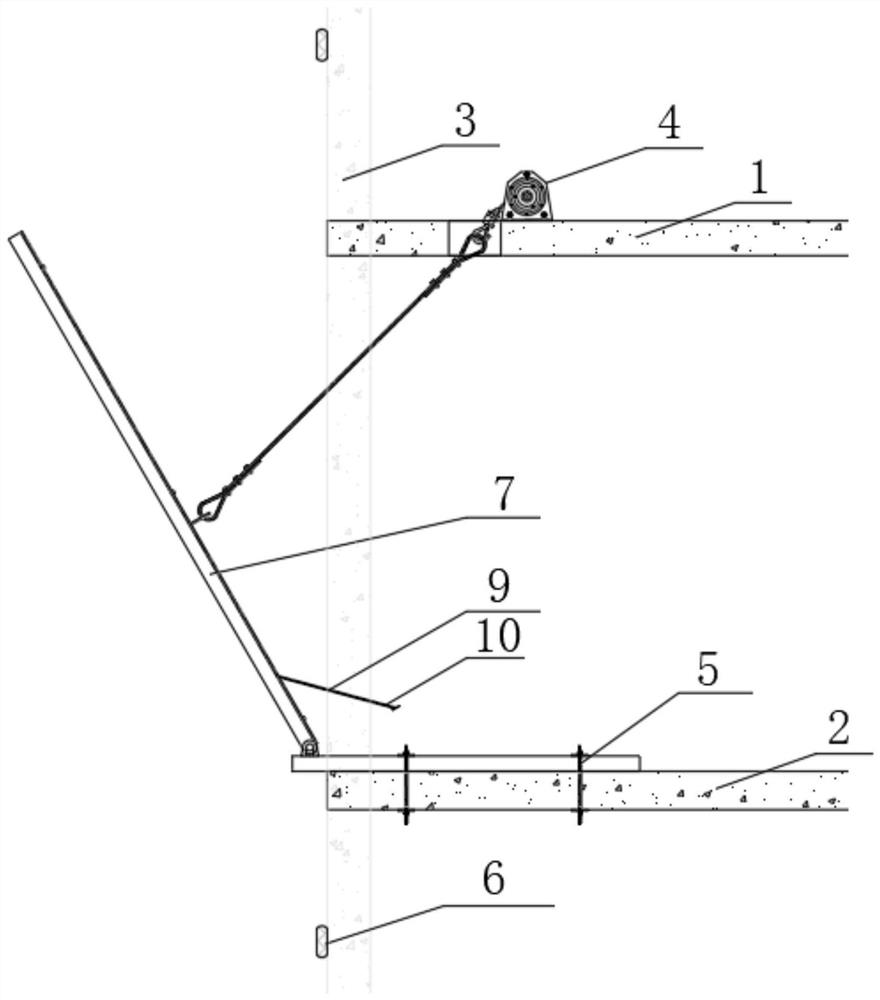

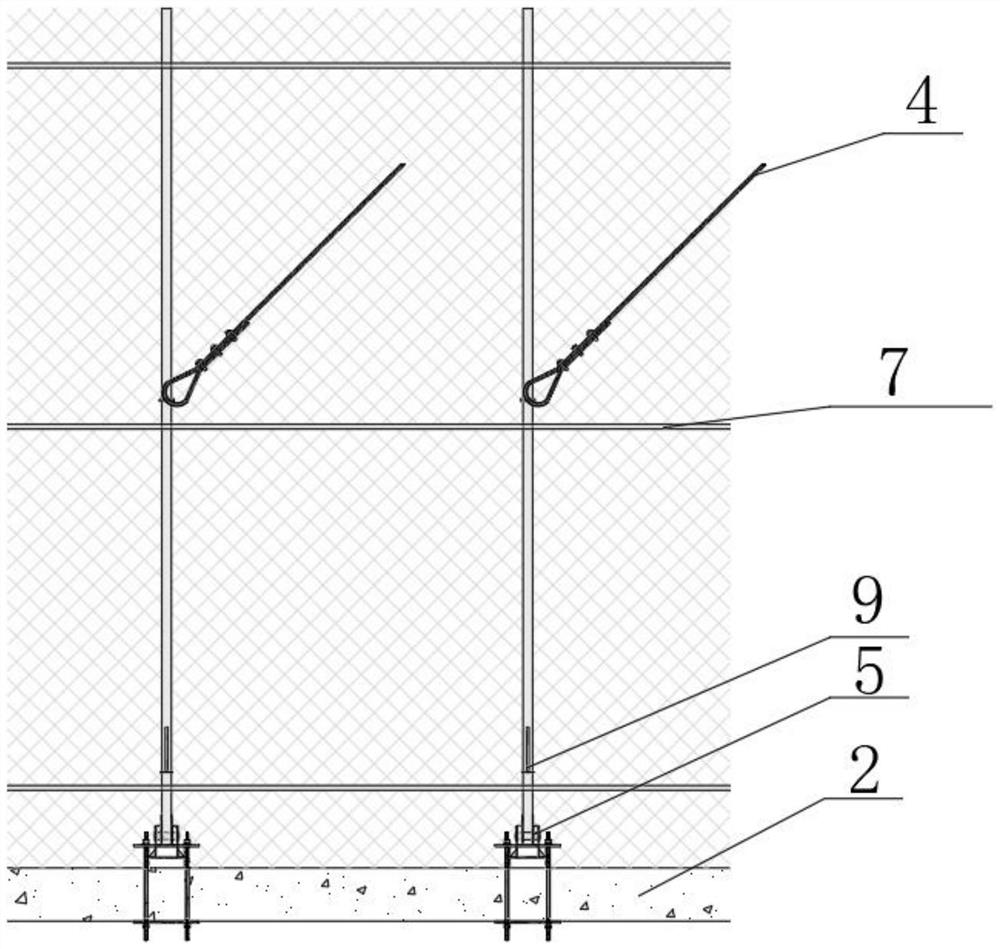

[0035] Such as figure 1 , figure 2 and Figure 9 As shown, a reversible anti-smashing device with remote control and automatic induction includes an upper board 1, a lower board 2 and a vertical board 3, and the upper board 1 and the lower board 2 are respectively provided with a rolling mechanism 4 and a fixing member 5, The facade panel 3 is provided with a plurality of position signal transceivers 6, the number of position signal transceivers 6 is two, the position signal transceivers 6 are position sensors, the fixing part 5 is provided with a protective net frame 7, and the output of the rolling poplar mechanism 4 End is connected with protective net frame 7, and a plurality of position signal transceivers 6 are positioned at the upper and lower sides of protective net frame 7 respectively;

[0036] The poplar mechanism 4 includes an intelligent remote control winch, a steel wire rope and a U-shaped lifting lug. The intelligent remote control winch is installed on the ...

Embodiment 2

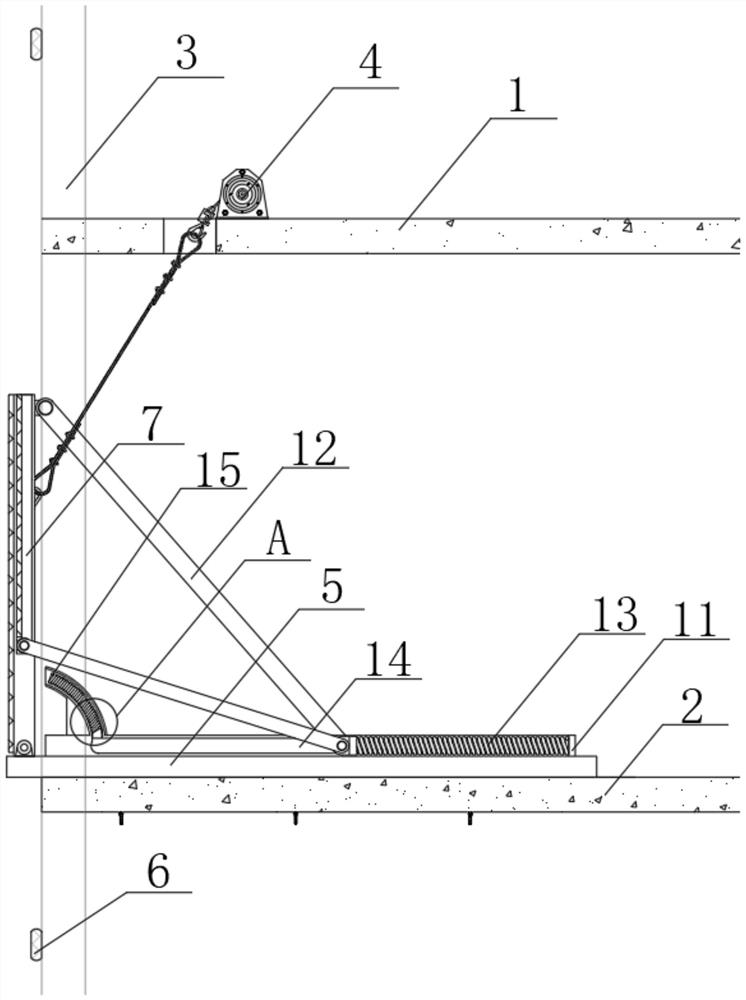

[0041] Such as image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 8 As shown, a reversible anti-smashing device with remote control and automatic induction, the protective screen frame 7 includes a first screen frame 71 and a second screen frame 72, a square frame 11 is arranged on the fixing part 5, and the square frame 11 and the A push rod mechanism 12 is arranged between the first screen frame 71 and the second screen frame 72;

[0042]The second screen frame 72 is arranged on the inside of the first screen frame 71, and one end of the first screen frame 71 is provided with a slide hole for accommodating the second screen frame 72, and the inside of the first screen frame 71 is provided with an anti-falling groove communicating with the slide hole, The second screen frame 72 is equipped with a slide block that is slidably connected with the anti-off groove, and the second screen frame 72 is positioned at an end of the first screen frame 71 inboard where a sliding...

Embodiment 3

[0045] Such as image 3 and Figure 6 As shown, a reversible anti-smashing device with remote control and automatic induction, a push-pull auxiliary mechanism 13 is arranged in the square frame 11, and the push-pull auxiliary mechanism 13 is connected with the push rod mechanism 12;

[0046] Push-pull auxiliary mechanism 13 comprises extension spring 131 and ring block 132, and ring block 132 links to each other with first connecting rod 123, and extension spring 131 quantity is a plurality of, and extension spring 131 two ends are connected with ring block 132 and square frame 11 respectively. The inner side is connected, and the elastic coefficient of the tension spring 131 is smaller than the elastic coefficient of the strong spring 152;

[0047] When the protective screen frame 7 was in the vertical state, the extension spring 131 was in a compressed state. During the overturning process of the protective screen frame 7, the extension spring 131 was formed with a lateral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com