Construction technology for butt joint of upper layer and lower layer of steel-concrete combined pipe shear wall

A construction process and combined pipe technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems affecting the use efficiency and project progress of the hoisting machinery, occupying the working time of the hoisting machinery, and tedious operation, so as to achieve enhanced reliability. stability and stability, ensure verticality, and accelerate the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

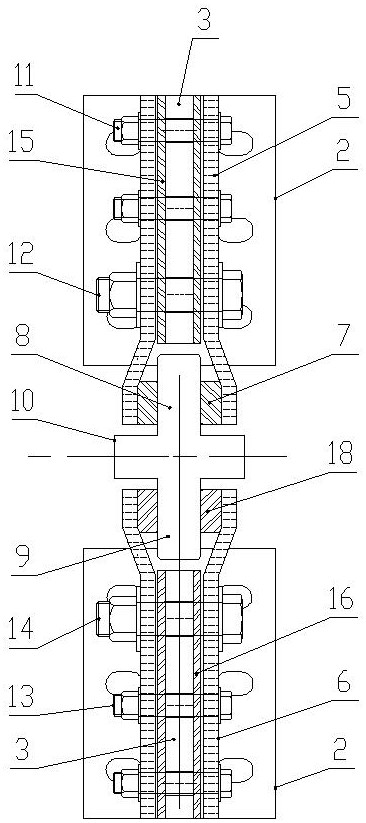

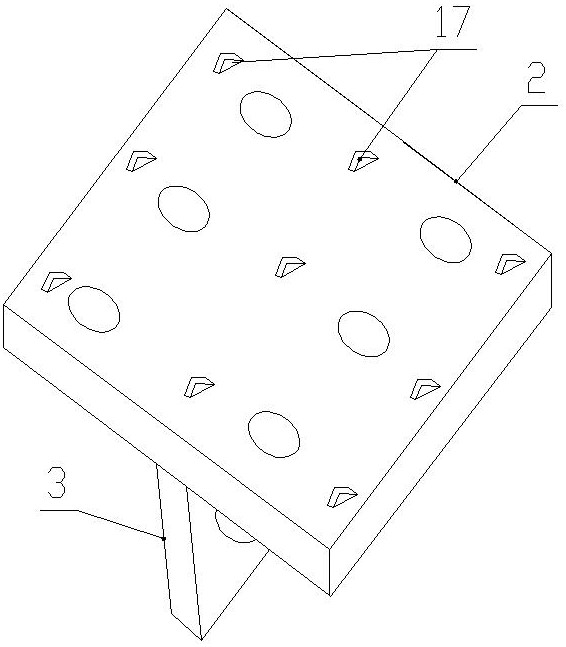

[0027] Such as Figure 1-Figure 5 As shown, the steel-concrete composite pipe shear wall butt joint construction process of the lower layer of the present invention comprises the following steps:

[0028] (1) When each steel-concrete composite pipe 1 of the steel-concrete composite pipe shear wall is prefabricated in the factory, the front and rear transparent perforations are reserved on the left and right sides of the upper and lower parts of the steel-concrete composite pipe 1;

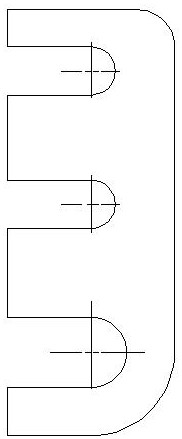

[0029] (2) Penetrate the double-ended connecting bolt 4 in the perforation, install the connecting seat at the front end and the rear end of the double-ended connecting bolt 4 respectively, tighten the nuts at both ends of the double-ended connecting bolt 4, and fasten the connecting seat and the steel-concrete composite pipe 1 As a whole; several adjustment and connection components are processed in the factory at the same time;

[0030] (3) Transport a number of adjustment connection components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com