Novel fan motor

A fan motor, a new technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of high friction force, low safety, and large motor noise, so as to reduce the friction force of rotation and facilitate installation , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

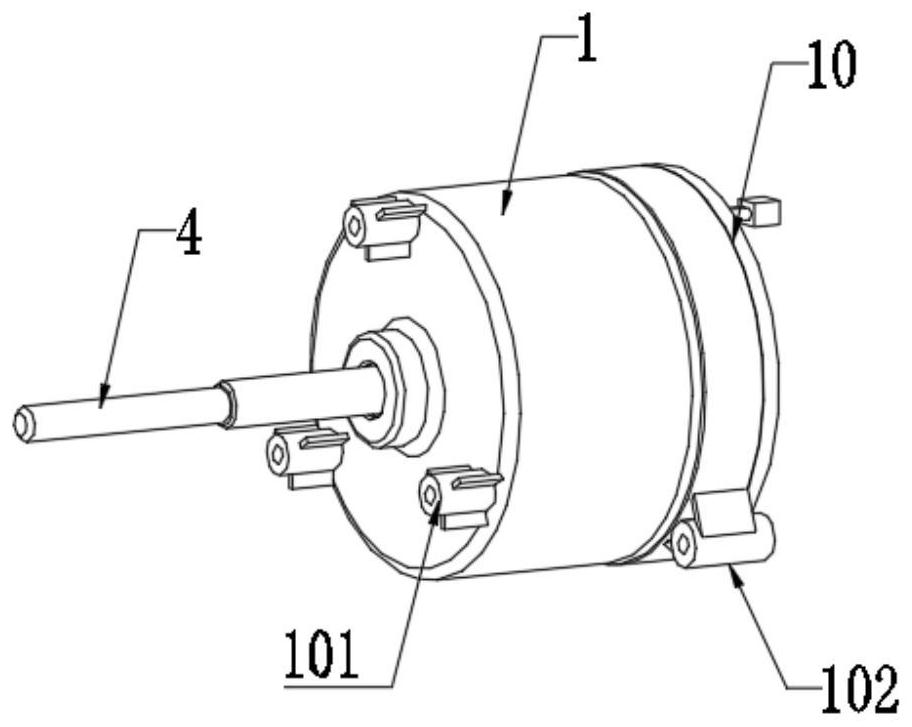

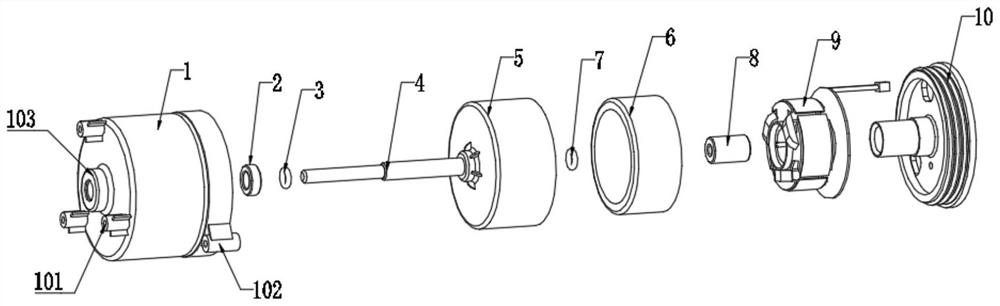

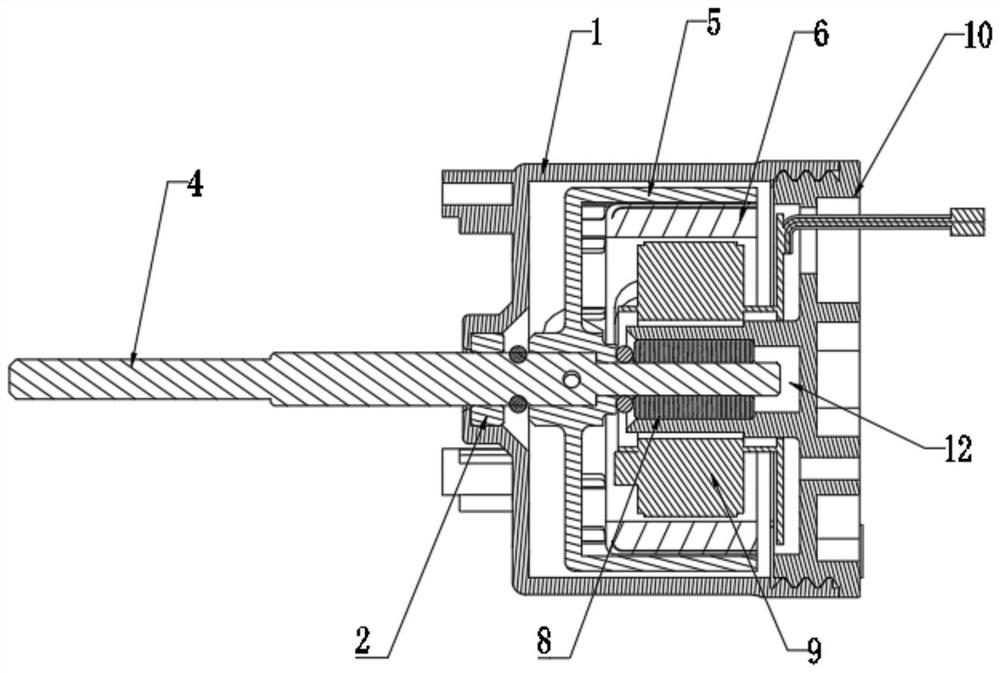

[0034] refer to Figure 1-4 , a new type of fan motor, including an outer cover 1, a first bearing 2, a first silicone ring 3, a rotating shaft 4, a magnetic ring seat 5, a magnetic ring 6, a second silicone ring 7, a second bearing 8, a DC spindle 9 and Motor base 10; threaded connection between the outer cover 1 and the motor base 10;

[0035] The DC spindle 9 is fixed on the motor base 10, the magnetic ring 6 is arranged in the magnetic ring base 5, and the magnetic ring 6 and the magnetic ring base 5 are kept coaxially connected; the magnetic ring base 5 and the magnetic ring 6 are sleeved on the DC spindle 9 On the outside, the rotating shaft 4 is penetrated and fixed on the magnetic ring seat 5, and the right end of the rotating shaft 4 is connected to the DC spindle 9 through the second bearing 8 for rotation;

[0036] A bearing installation part 103 is provided in the middle part of one side of the outer cover 1, and the bearing installation part 103 is a cylindrical ...

Embodiment 2

[0055] refer to Figure 5-6 , the present embodiment adds the following technical solution on the basis of the first embodiment: the rear side end of the motor base 10 and the cover 1 is provided with an oscillating bracket fixing mechanism;

[0056] The oscillating head bracket fixing mechanism includes two oscillating head bracket fixing posts 102 symmetrically arranged on the right side of the outer cover 1 and the mounting hole 11 on the right side of the motor base 10. There are threaded holes inside, the mounting hole 11 and the oscillating head bracket fixing column 102 are on the same vertical plane, and the mounting hole 11 and the two oscillating head bracket fixing columns 102 form an isosceles triangle mounting bracket, through the stability of the triangle, Thereby, the connection between the motor and the oscillating device is more stable, and the shaking of the motor and the fan is reduced.

[0057] The right side end of the motor base 10 is also provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com