Composition, oil-free lubrication engineering machinery sliding block and application

A technology for construction machinery and oil-free lubrication, which is used in the field of oil-free lubrication of construction machinery modules and the preparation of compositions for oil-free lubrication of construction machinery modules. problems, to achieve the effect of being conducive to popularization and utilization, retention of mechanical properties and toughness, and improvement of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

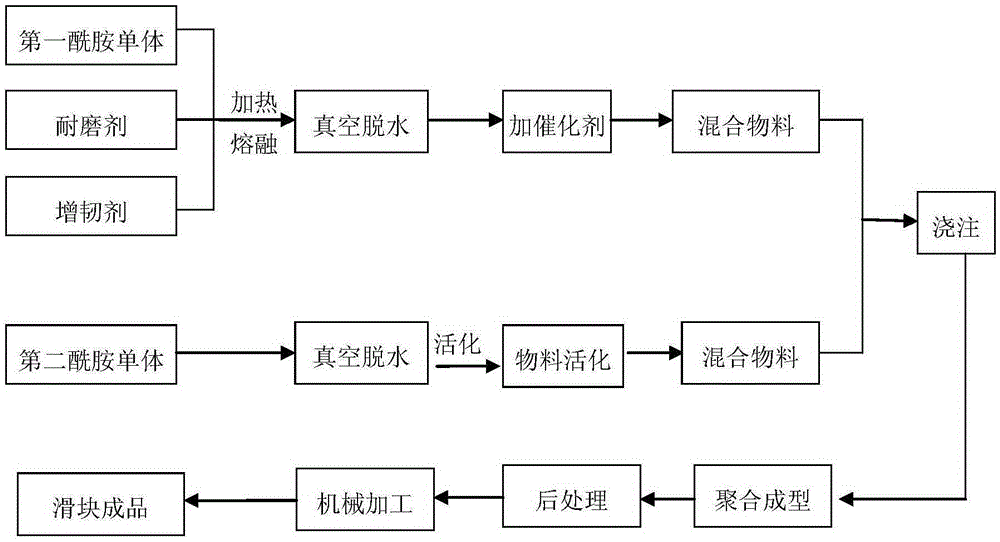

Method used

Image

Examples

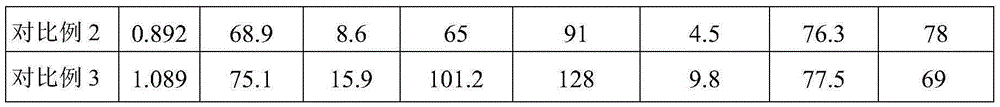

Embodiment 1

[0044] Melt 50 parts of caprolactam, 3 parts of PTFE micropowder (MP1200), and 3 parts of polyol (polyether polyol PPG-2000) toughening agent, add 0.16 parts of sodium hydroxide after dehydration, and vacuum dehydrate to obtain Mixture A. Melt 50 parts of caprolactam, then dehydrate, add 0.6 parts of isocyanate to obtain the mixed material B, pass the mixed materials A and B through the mixing head, inject the mold, and then perform the casting process, obtain the blank after polymerization, and perform post-treatment on the blank , to get the module. Perform a performance test on the obtained module, and the performance test results are shown in Table 1.

Embodiment 2

[0046] Melt 50 parts of caprolactam, 5 parts of PTFE micropowder (MP1200), and 1 part of polyol (polyether polyol PPG-2000) toughening agent, add 0.16 parts of sodium hydroxide after dehydration, and vacuum dehydrate to obtain Mixture A. Melt 50 parts of caprolactam, then dehydrate, add 0.6 parts of isocyanate to obtain the mixed material B, pass the mixed materials A and B through the mixing head, inject the mold, and then perform the casting process, obtain the blank after polymerization, and perform post-treatment on the blank , to get the module. Perform a performance test on the obtained module, and the performance test results are shown in Table 1.

Embodiment 3

[0048] 50 parts of caprolactam and 3 parts of PTFE micropowder (MP1200) were melted, and after dehydration, 0.16 parts of sodium hydroxide were added to obtain a mixed material A. Melt 50 parts of caprolactam, then dehydrate, add 0.6 parts of isocyanate to obtain the mixed material B, pass the mixed materials A and B through the mixing head, inject the mold, and then perform the casting process, obtain the blank after polymerization, and perform post-treatment on the blank , to get the module. Perform a performance test on the obtained module, and the performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com