Extrusion device for curved profiles

A technology for extrusion devices and profiles, which is applied in the field of extrusion devices, can solve problems such as the inability to change the cross-section of profiles, and achieve the effect of reducing downtime and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

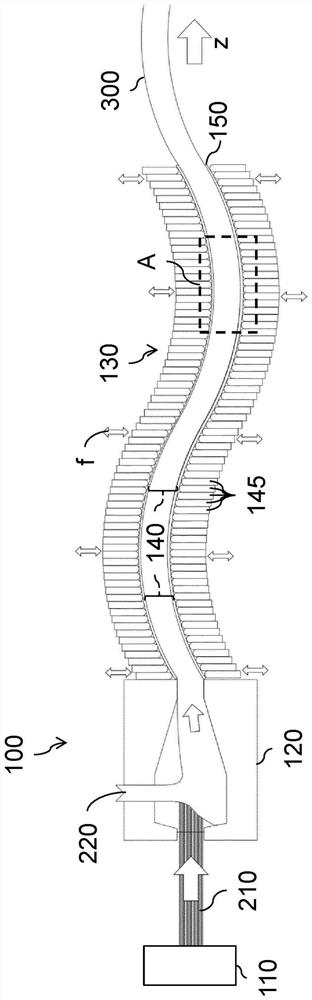

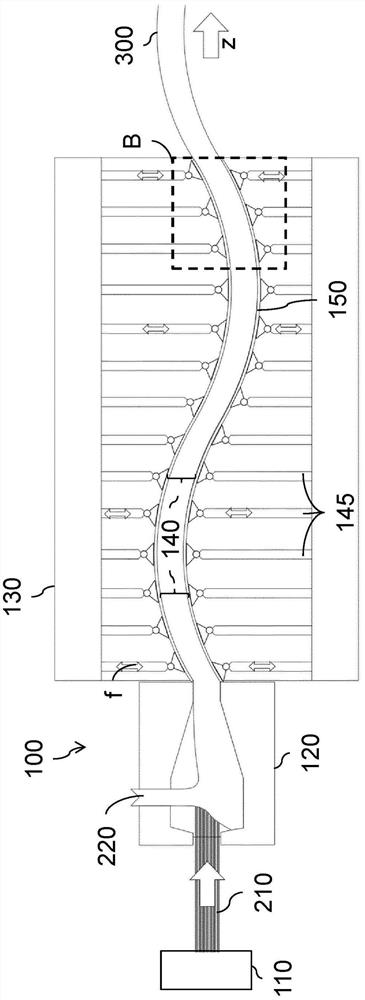

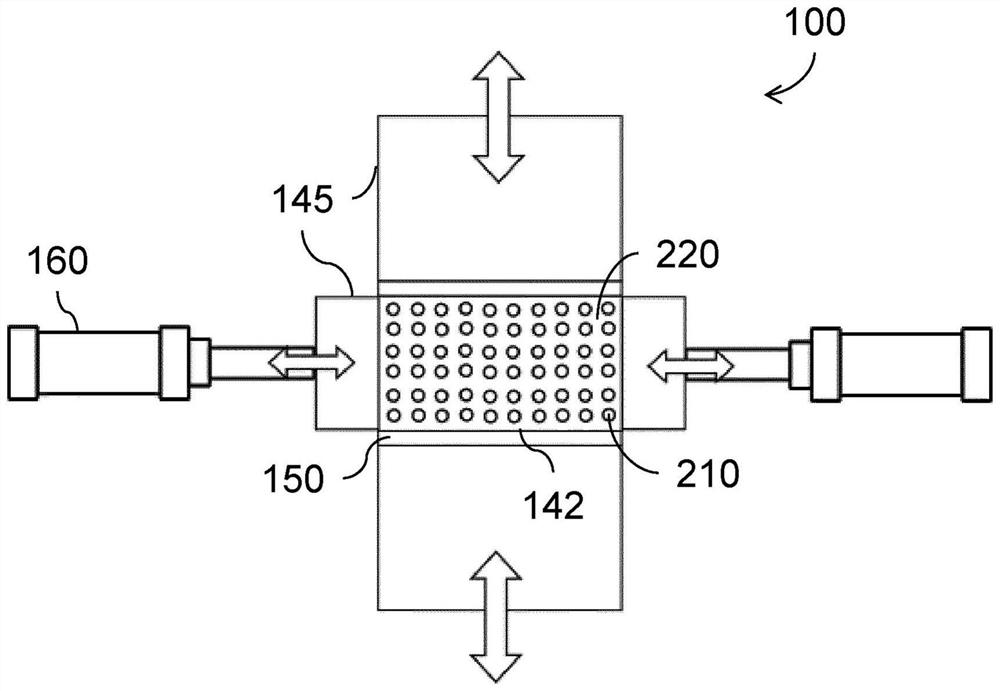

[0030] Figure 1AA cross section through the extrusion device 100 is shown schematically along the movement direction z of the fiber bundle 210 conveyed in the extrusion device 100 . The extrusion device 100 has a fiber feeder 110 , an impregnation die 120 and a forming die 130 .

[0031] The fiber bundles 210 are withdrawn from the fiber feeder 110 and are guided from there into the impregnation mold 120 . The fiber feeder 110 may be, for example, a plurality of fiber spools providing fibers of the fiber tow. It can be a single fiber, or it can be a fabric, etc. The fiber bundle 210 and the fiber feeder 110 here correspond to components known from the prior art. Therefore, there is no need to discuss this further.

[0032] In the impregnation die 120, the fiber bundle 210 is impregnated with an extruded matrix 220, such as a resin. This step also corresponds to the usual practice known from the prior art. Both the impregnation die 120 and the extrusion matrix 220 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com