Mobile robot with adjustable traction counterweight

A mobile robot and robot technology, applied in the field of mobile robots, can solve the problems of increasing the risk of tilting of braking performance, increasing the energy consumption of mobile robots, etc., to reduce the risk of tipping over, reduce the overall energy efficiency, and optimize the effect of traction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

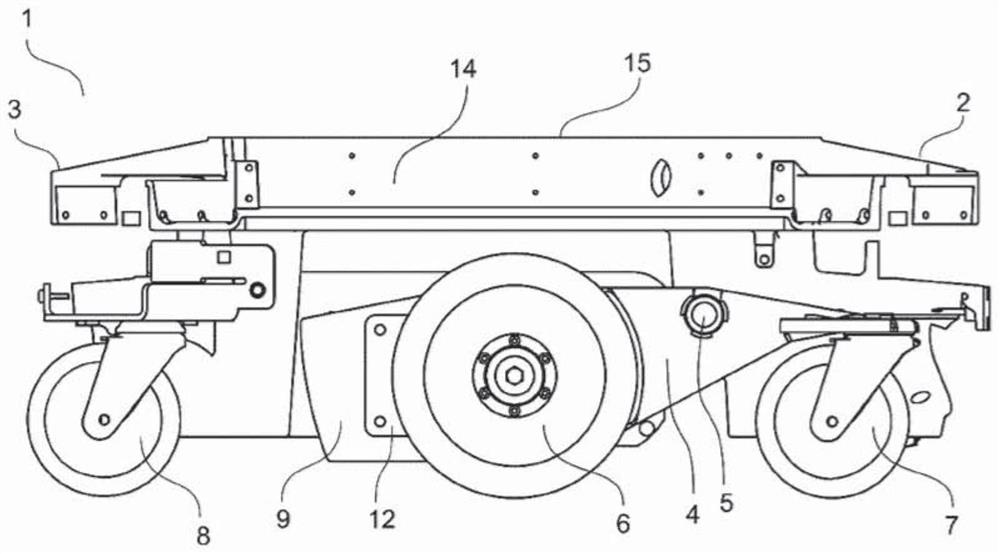

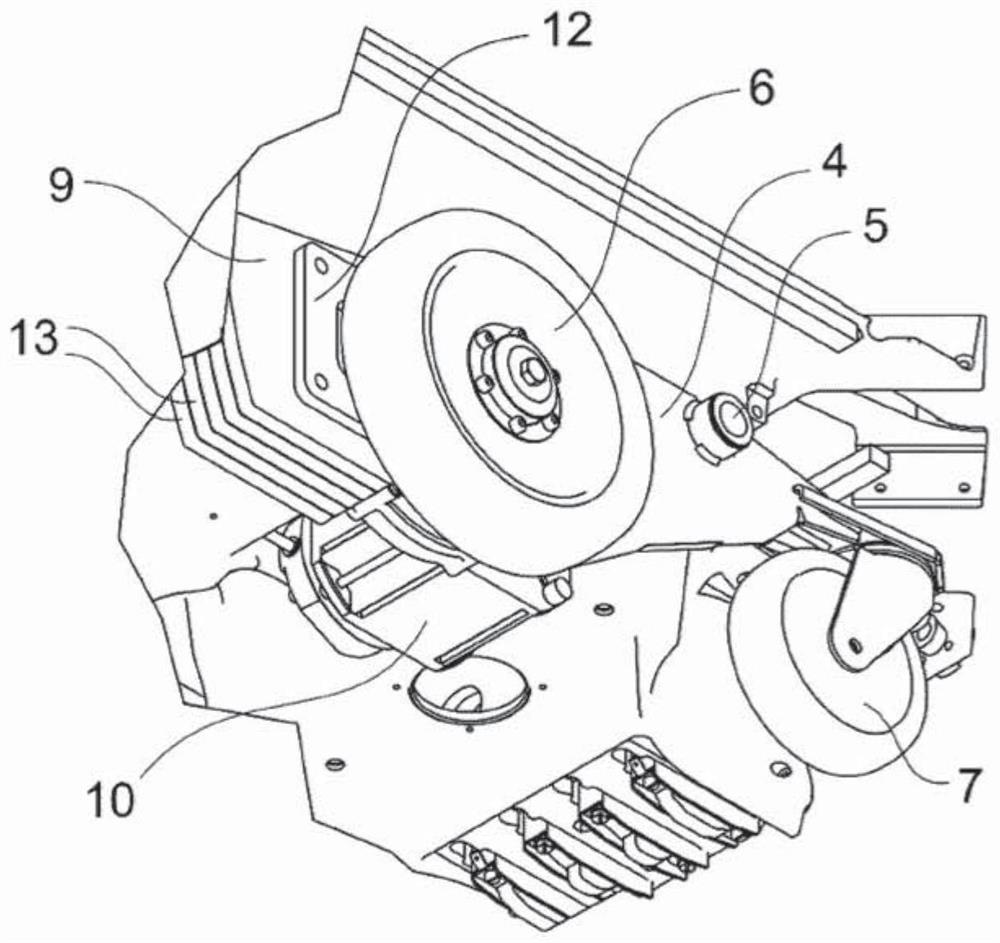

[0058] This chapter describes the creative design of bogie arm 4 and traction counterweight 9( Figure 1A B), by attaching one or more counterweight modules 13 to the bogie arm extension 12, the gravity acting on the driving wheel 6 and the generated friction can be increased, and the generated gravity acting on the (front) caster 7 can be reduced due to the cantilever effect. Therefore, it is relatively easy to achieve sufficient traction for the intended application on the driving wheel 6 without affecting the safety, and the impact on the overall energy efficiency of the mobile robot 1 is minimal.

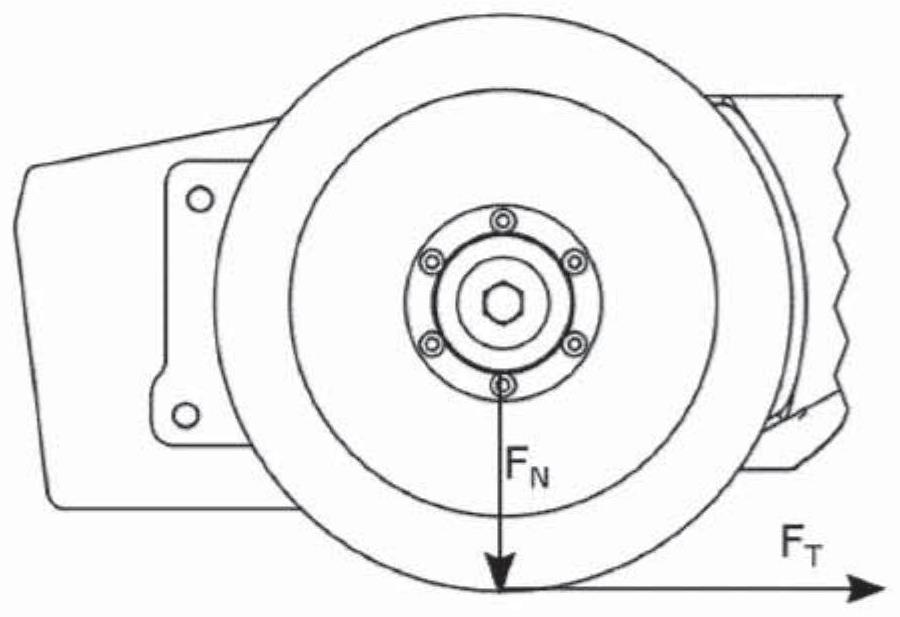

[0059] The available traction force of the driving wheel 6 of the mobile robot is directly proportional to the normal force generated by the gravity of the robot on the ground and depends on the friction coefficient between the ground and the wheel thread( Figure 2A ):

[0060] F T =F N * μ

[0061] among μ Is the coefficient of friction; F N Is the normal force.

[0062] The robot d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com