Coal-water separation device and method for underground downhill driving working face

A technology of excavation working face and separation device, which is applied in the direction of separation method, chemical instrument and method, solid adsorbent liquid separation, etc. It can solve the problems of high manual labor intensity, pollution of underground working environment, and large consumption of water-absorbing materials. Achieve high work efficiency, prevent idling and frequent start-up, and be safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments will be described in detail hereinafter, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following examples do not represent all implementations consistent with this application. These are merely examples of systems and methods consistent with aspects of the present application as recited in the claims.

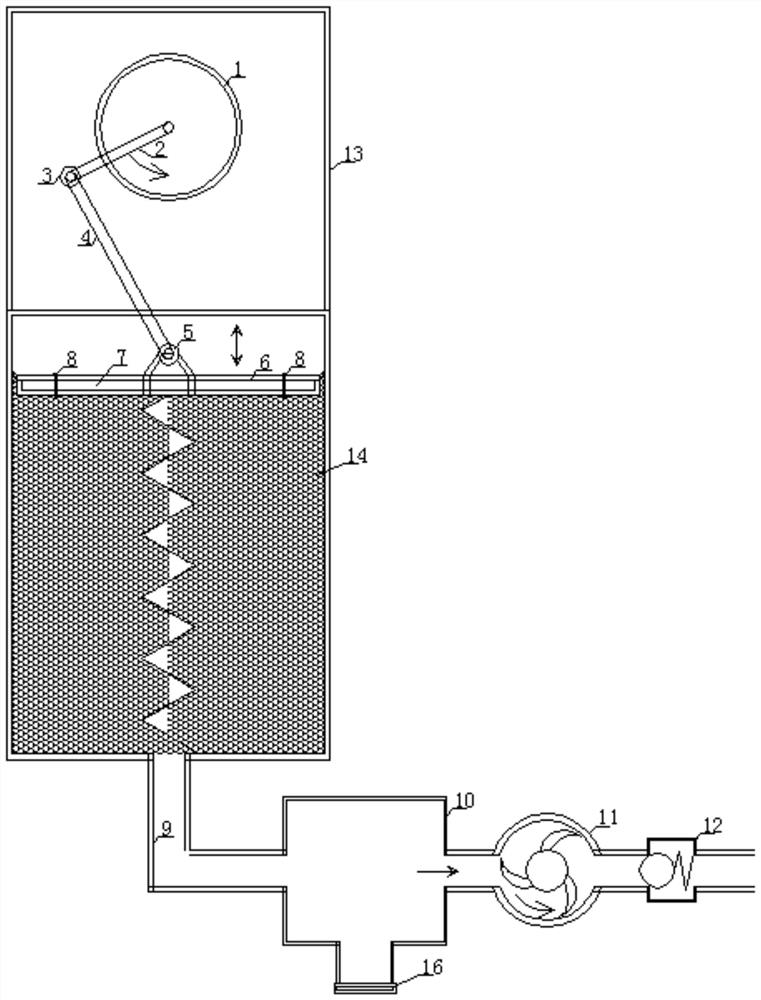

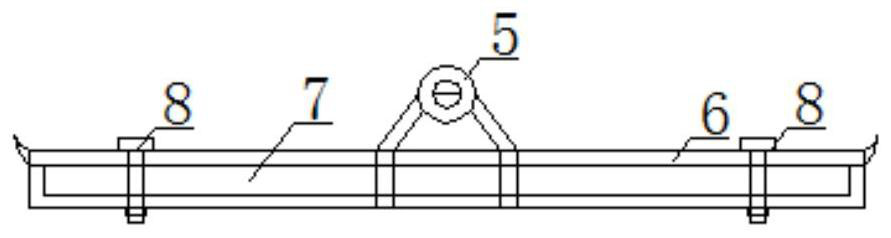

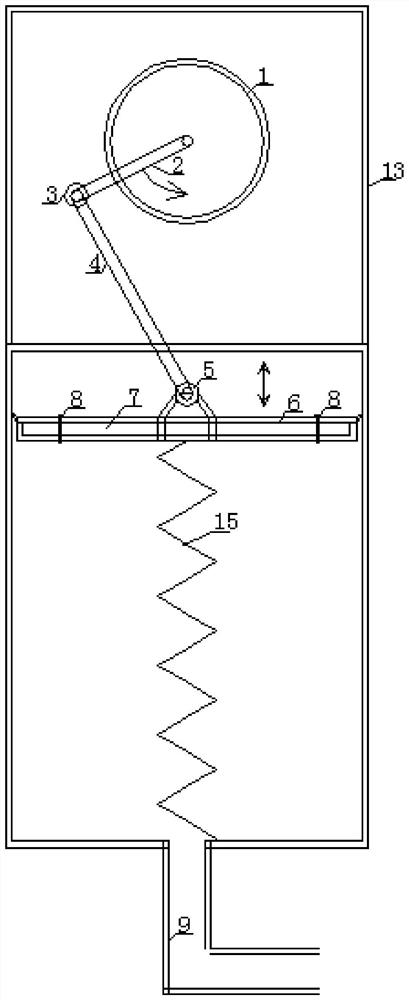

[0056] see figure 1 , which is a structural schematic diagram of a coal-water separation device used in the underground tunneling face of the application.

[0057] The present application provides a coal-water separation device used in the underground driving face, in one embodiment, it includes a drive mechanism 1, a transmission mechanism, a mud scraper 6, and a compression plate 7 arranged in the filter water collection shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com