Fire-fighting valve core assembly machine

An assembly machine and assembly mechanism technology, applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problem of low assembly efficiency, and achieve the effect of improving efficiency, ensuring integrity, and saving assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

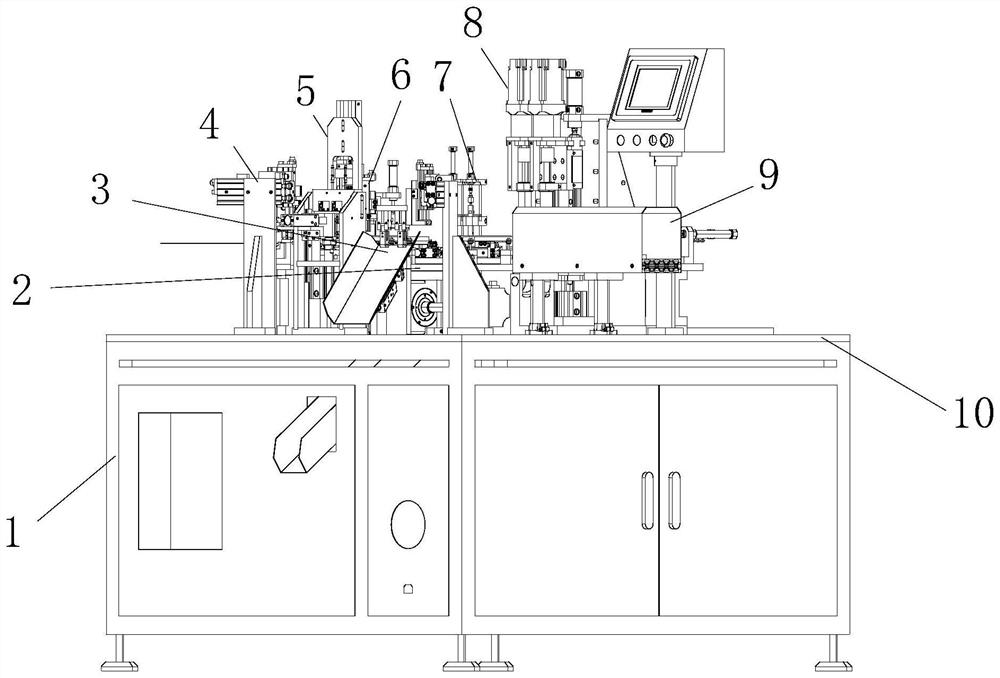

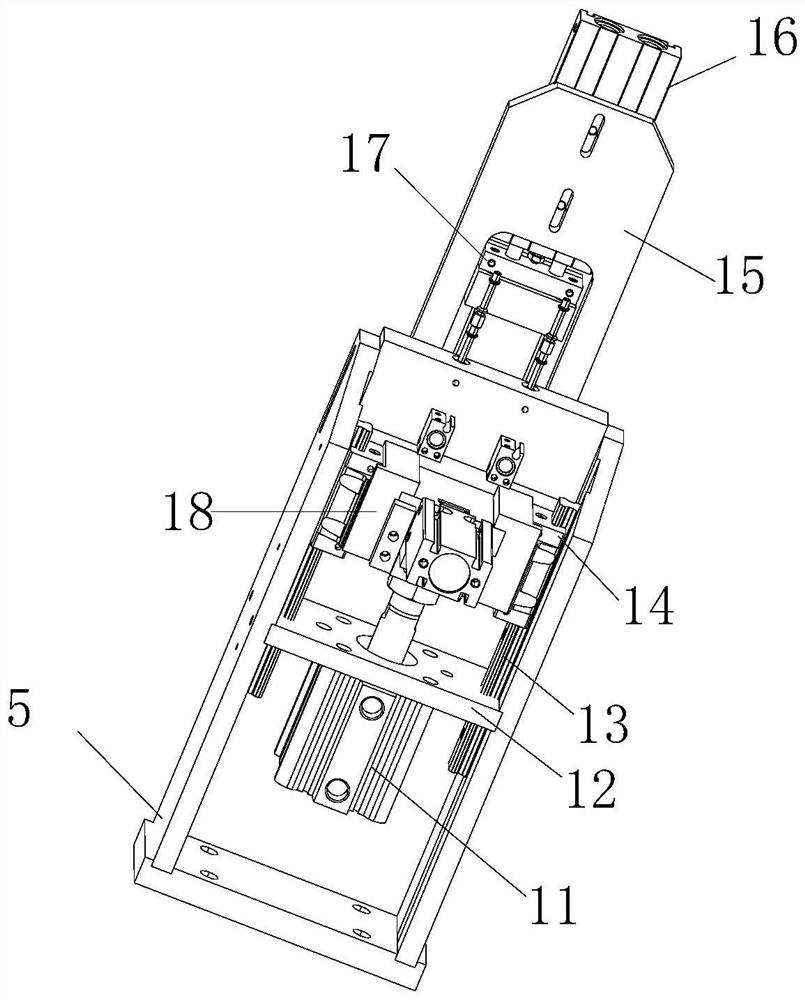

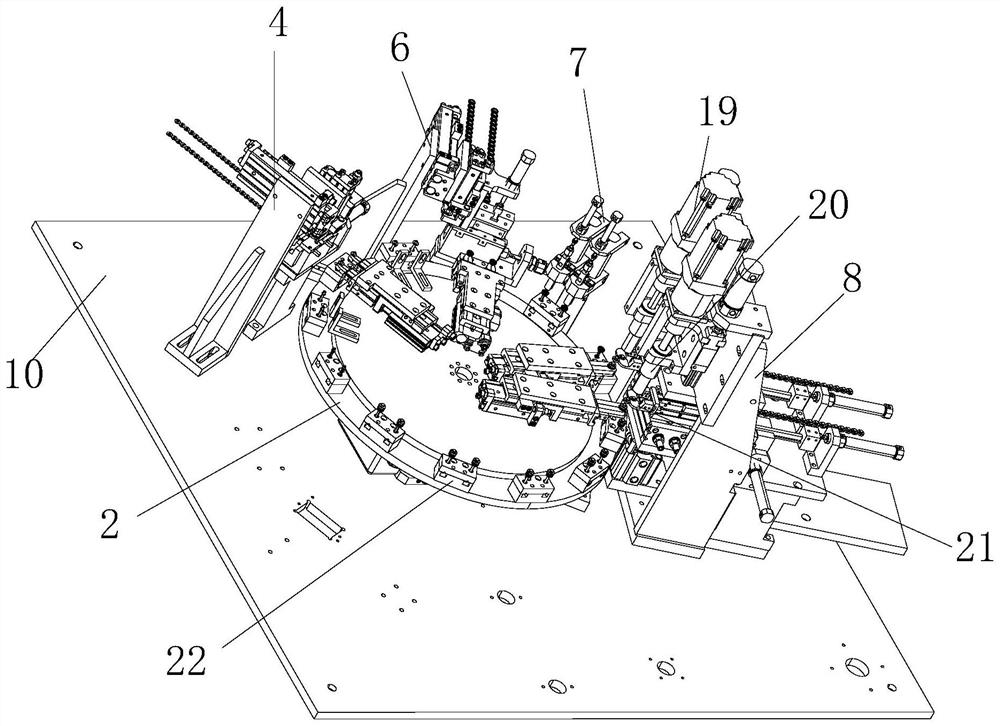

[0021] see Figure 1 to Figure 3 , the present invention provides a technical solution: fire valve spool assembly machine, including a cabinet 1, an assembly platform 10 is installed on the cabinet 1, a turntable mechanism 2 is installed at the center of the assembly platform 10, and the outer sides of the turntable mechanism 2 are respectively arranged There are stem assembly mechanism 5, gasket assembly mechanism 4, O-ring assembly mechanism 6 and bonnet assembly mechanism 8, and the designed valve stem assembly mechanism 5, gasket assembly mechanism 4, O-ring assembly mechanism 6 and bonnet assembly mechanism 8. Each mechanism cooperates with each other, and each component is transported to the turntable mechanism 2 to realize assembly. The valve stem assembly mechanism 5 is composed of two sets of ribs, a fixed plate 12 and a support plate 15, and the fixed plate 12 is installed on two sets of ribs. The inner side of the plate, the bottom of the fixed plate 12 is fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com