Remote management method and equipment for injection molding machine

A technology for remote management equipment and injection molding machines, which is applied in the remote management method and equipment field of injection molding machines, can solve problems such as inconvenient control and management, inability to remotely monitor the operation and working conditions of injection molding machines, and injection molding machines without networking functions, etc., to achieve improvement The effect of service life and use stability, high-efficiency replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

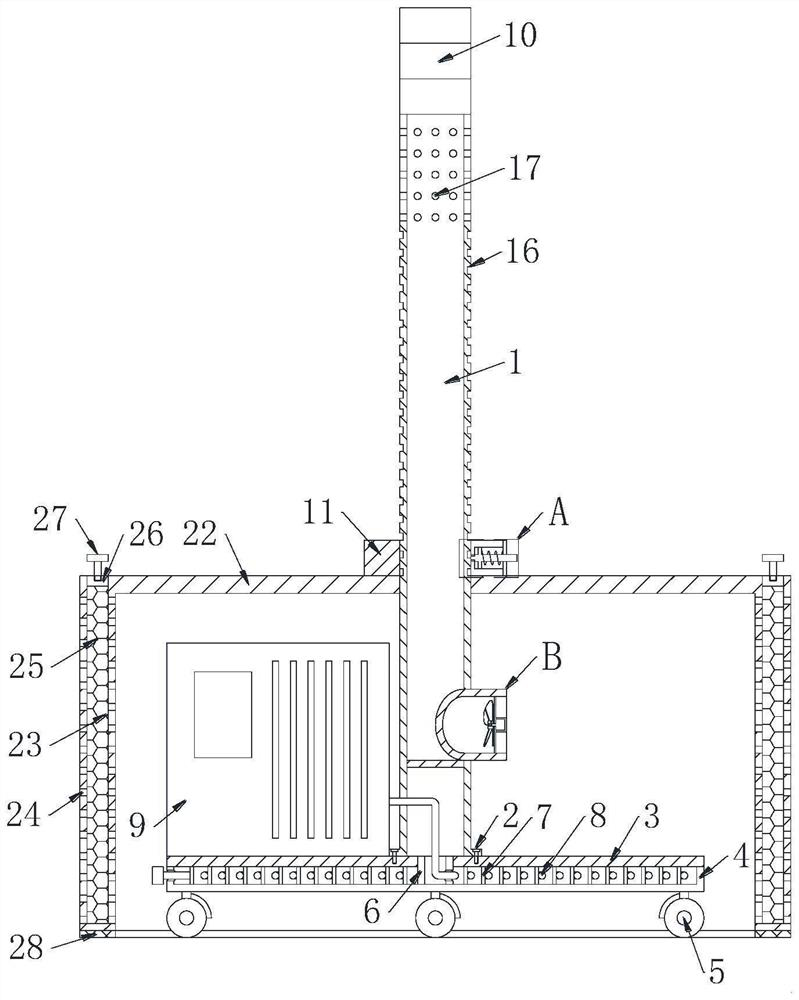

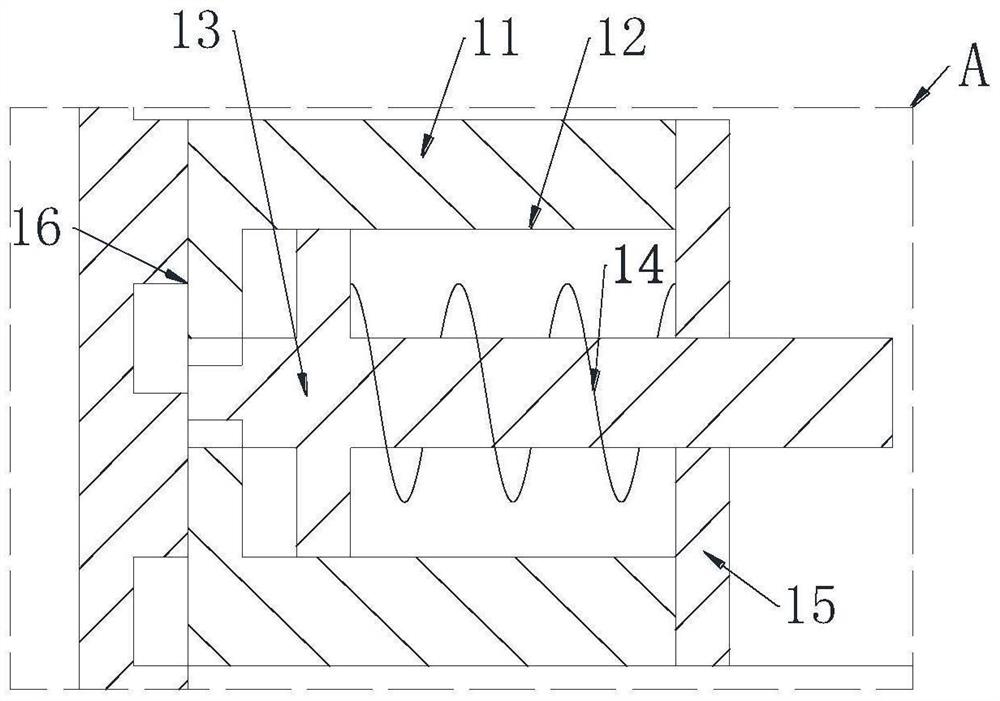

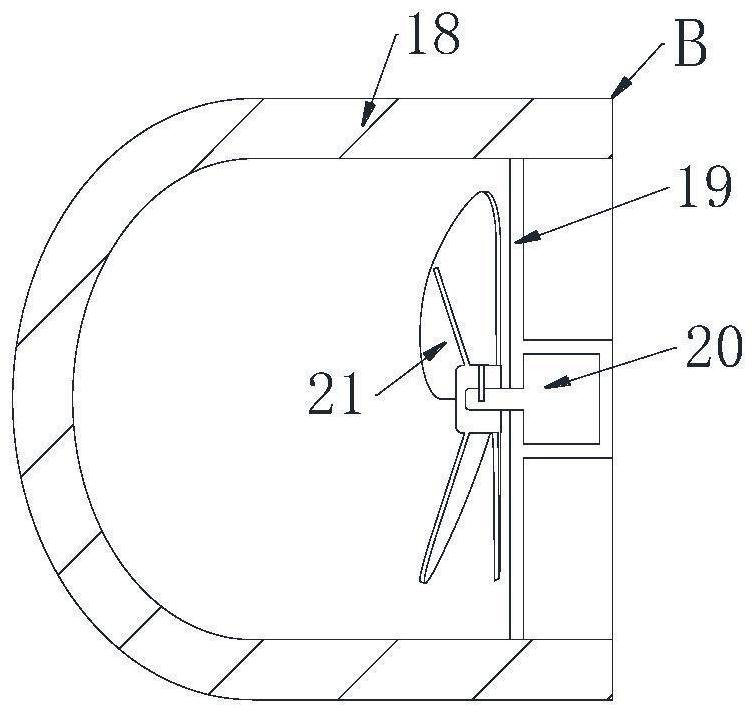

[0030] see Figure 1-5 As shown, a remote management method and equipment for an injection molding machine, including a support tube 1, a fastener 2, a load-bearing plate 3 and a remote unit; the lower end of the support tube 1 is inserted with a fastener 2; A load-bearing plate 3 is screwed on the fastener 2; a remote unit is provided on the load-bearing plate 3; the remote unit includes a spacer cover 4, a universal wheel 5, an intermediate pipe 6 and a coil spring 7; the spacer cover 4 is affixed to the lower surface of the load-bearing plate 3; the lower surface of the spacer cover 4 is fixedly connected with a plurality of universal wheels 5; the lower surface of the load-bearing plate 3 is fixed with an intermediate pipe 6 corresponding to the opening of the spacer cover 4; A coil spring 7 is sleeved on the intermediate tube 6; a cable 8 is sleeved on the surface of the coil spring 7; the upper end of the cable 8 is electrically fixed to an industrial computer 9; the ind...

Embodiment 2

[0042] see Image 6 As shown in Comparative Example 1, as another embodiment of the present invention, the corresponding fan blade 21 on the air inlet pipe 18 is detachably fixed with a dust-proof net 29; during operation, the dust-proof net 29 made of metal , making it possible to prevent bulky objects from entering the intake pipe 18 and contacting the fan blade 21, thereby ensuring the normal operation of the fan blade 21, and also preventing the danger caused by the contact between the body parts of the staff and the fan blade 21.

[0043] The working principle is to realize the wired connection between the industrial computer 9 and the injection molding machine through the cable 8 and the PLC of the injection molding machine, and to realize the remote viewing of the working status of the injection molding machine and the work of the injection molding machine through the wireless connection between the industrial computer 9 and the Internet. Data, and can record the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com