Push-leaning type rotary guiding device

A technology of rotary steering and conductive slip ring, which is applied in the direction of rotary collector, directional drilling, measurement, etc., can solve the problems of unable to correct the drilling trajectory in time, increase the area of the piston, and increase the size of the hydraulic system. Effects of power supply and communication, improvement of ramping ability, and reduction of design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the purpose, structure and function of the present invention, a push-type rotary guide device of the present invention will be described in further detail below with reference to the accompanying drawings.

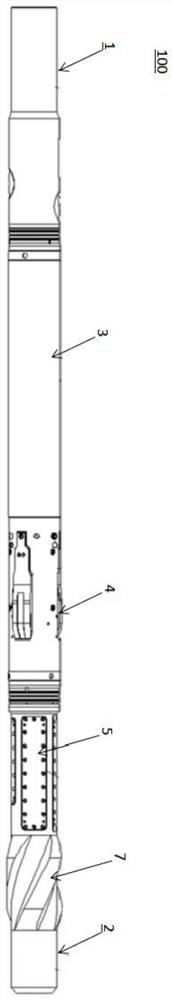

[0025] figure 1 It is a schematic structural diagram of some embodiments of the push-type rotary guide device according to the embodiment of the present invention;

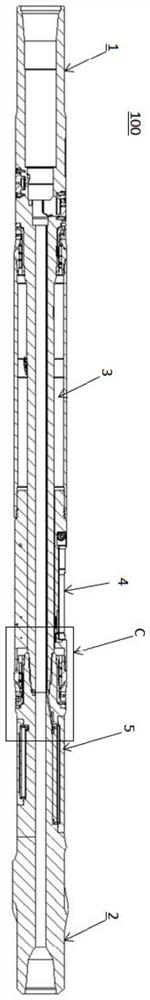

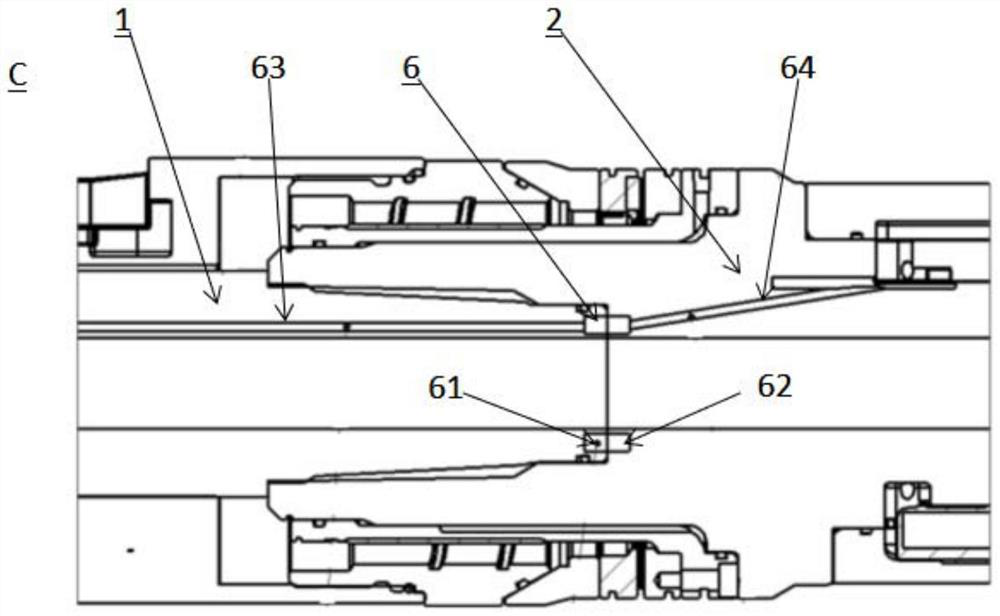

[0026] figure 2 It is a schematic cross-sectional view of the structure of some embodiments of the push-type rotary guide device according to the embodiment of the present invention. combine figure 1 , figure 2 as well as Figure 5 As shown, the push-type rotary guide device 100 includes: an upper driving shaft 1 and a lower driving shaft 2, the upper driving shaft 1 and the lower driving shaft 2 are coaxially arranged and fixedly connected, and the upper driving shaft 1 is used for connecting with an external driving device , the end of the lower drive shaft 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com