Annular pressure-resistant shell device suitable for submersible

A technology for submersibles and pressure hulls, applied in the direction of ships, etc., can solve the problems of increasing the structural weight and welding requirements of the pressure hull, increasing the diameter of the pressure hull, etc., so as to reduce the amount of structural welding, reduce structural components, reduce Effects of Minimum Stress Levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

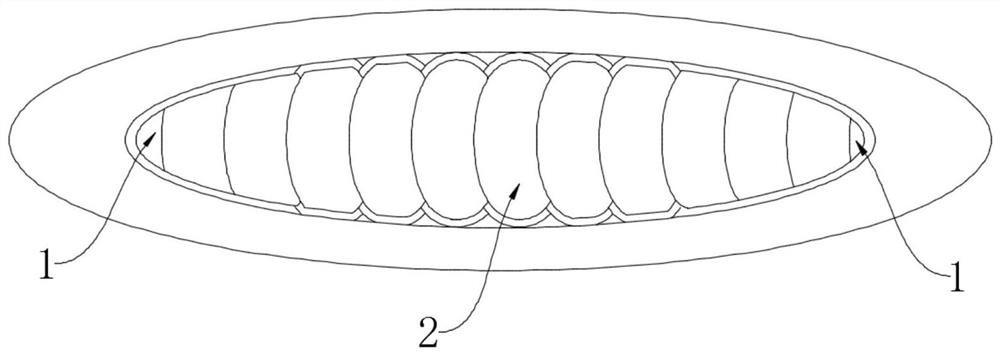

[0043] refer to figure 1 , different from Embodiment 1, a method for making an annular pressure hull device suitable for a submersible, comprising the following steps:

[0044] S1: Cutting, cutting out the cut surfaces on both sides of the initial spherical structure of the spherical pressure vessel manufactured according to the requirements, so as to facilitate the subsequent connection and fixing of multiple spherical annular pressure vessels;

[0045] S2: According to the radius of the inner ring and the radius of the outer ring of the curved ring-shaped sphere, calculate the thickness of the curved ring-shaped sphere, and the thickness of the ring = the radius of the outer ring R-the semi-ring of the inner ring r, and select a suitable sphere according to the thickness of the curved ring ;

[0046] S3: calculate liquid pressure both P=ρgh according to the pressure of submersible in liquid;

[0047] p—liquid pressure (Pa)

[0048] ρ—liquid density—kilogram / cubic meter (k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com