Sewage treatment tank with steel fixing structure

A sewage treatment pool and fixed structure technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problem of poor desilting and sludge diversion effects affecting the water quality of sewage treatment pools Purification effect and other issues, to achieve the effect of improving mud removal effect and mud discharge efficiency, good sludge diversion effect, and good water purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

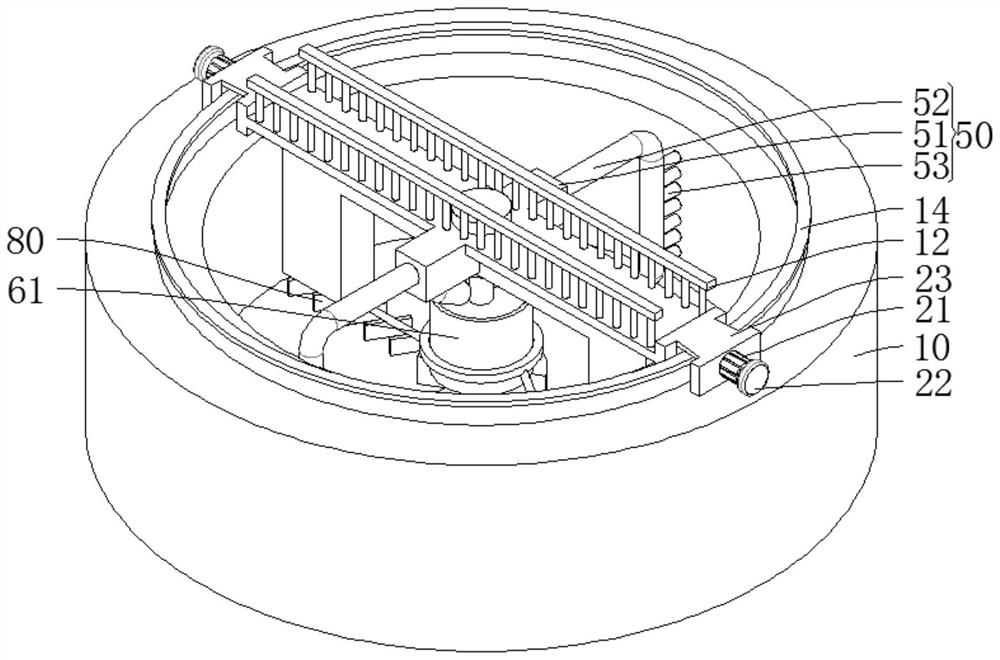

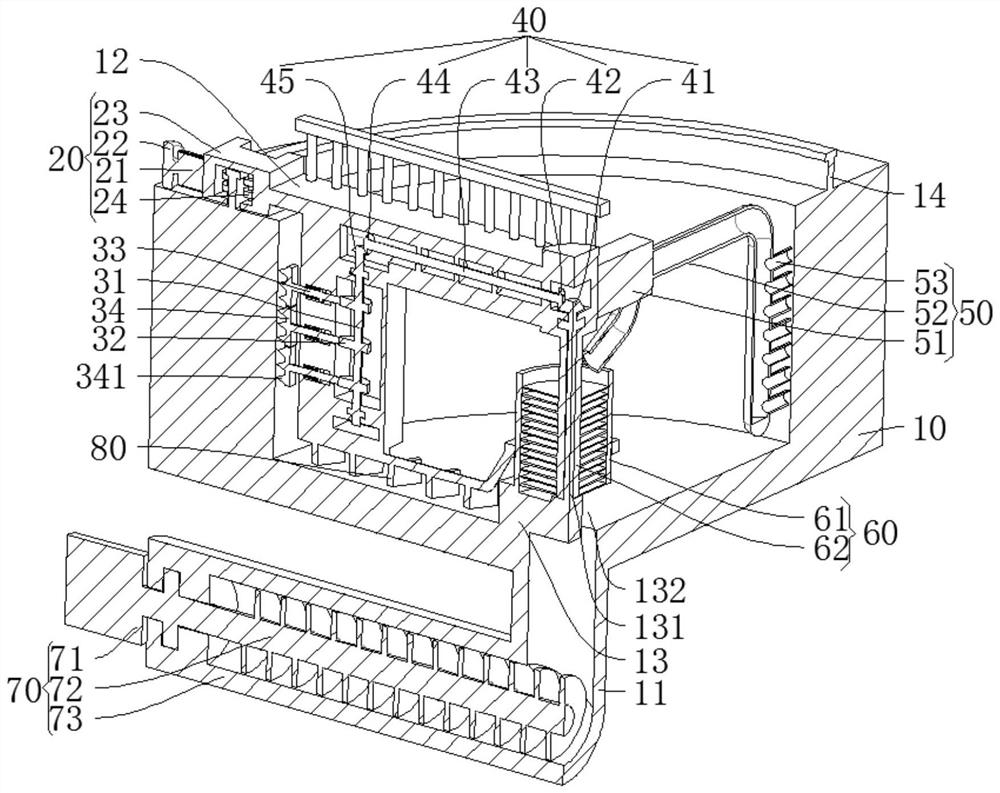

[0034] refer to Figure 1 to Figure 6 , the invention provides a sewage treatment tank with a steel fixed structure, comprising:

[0035] Pool body 10, sludge pipe 11, turret 12 and center platform 13 are arranged on the pool body 10, turret 12 is rotatably installed on the center platform 13, and turret 12 is provided with a drive mechanism 20 for driving turret 12 to rotate ;

[0036] The desilter mechanism 30, the desilter mechanism 30 is arranged on the turret 12 and can crush the sludge on the side wall of the tank body 10;

[0037] The transmission mechanism 40, the transmission mechanism 40 is arranged on the turret 12 and can cooperate with the rotation process of the turret 12 to drive the mud removal mechanism 30 to perform mud scraping work;

[0038] A mud suction mechanism 50, the mud suction mechanism 50 is arranged on the turret 12 and is used to collect the sludge in the tank body 10;

[0039] A mud guide mechanism 60, the mud guide mechanism 60 is arranged o...

Embodiment 2

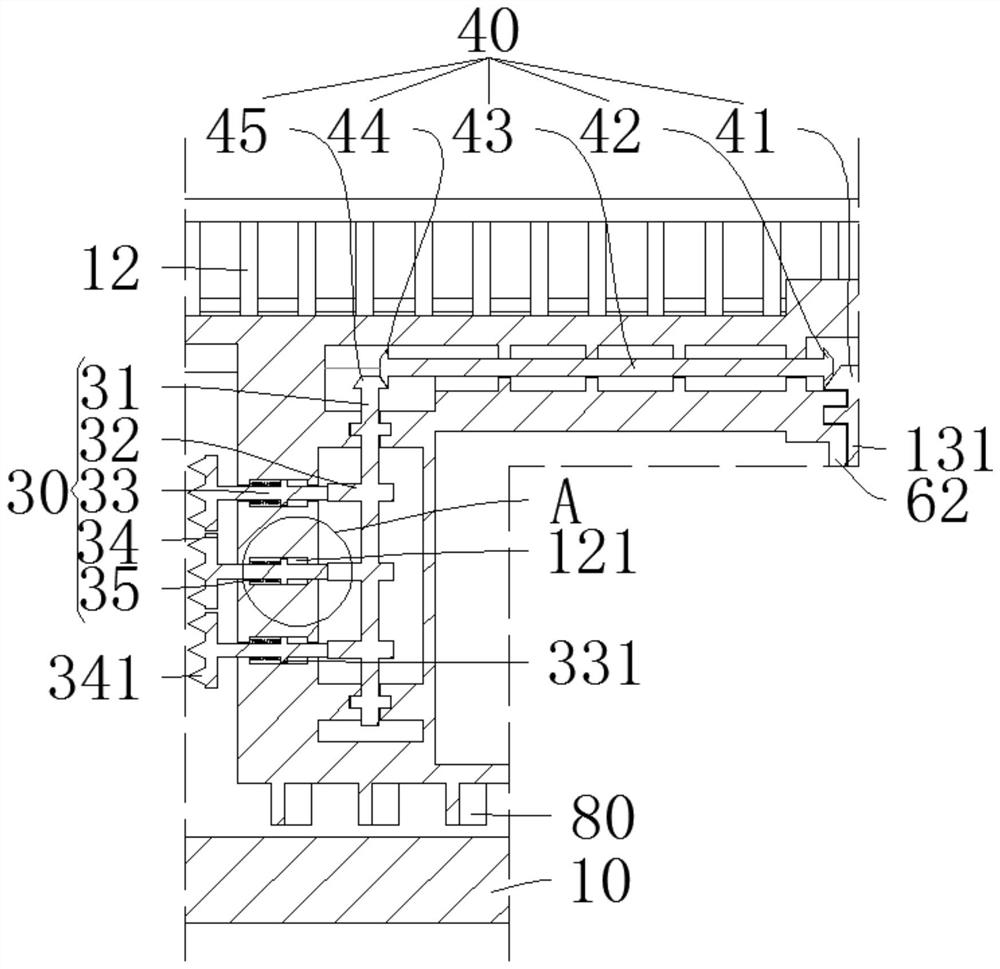

[0050] refer to Figure 1 to Figure 6 , in conjunction with the technical scheme of embodiment 1, in the present embodiment, transmission mechanism 40 comprises central bevel gear 41, main bevel gear 42, transmission rod 43, from bevel gear 44 and transmission bevel gear 45, center table 13 is provided with center column 131, the central bevel gear 41 is arranged on the central column 131, the main bevel gear 42 meshes with the central bevel gear 41, the main bevel gear 42 and the slave bevel gear 44 are both arranged on the transmission rod 43, and the transmission rod 43 is rotatably installed on the turret 12 Above, the transmission bevel gear 45 meshes with the slave bevel gear 44, and the transmission bevel gear 45 is arranged on the rotating rod 31 and can drive the rotating rod 31 to rotate.

[0051] When the turret 12 rotates, the main bevel gear 42 revolves around the central bevel gear 41 and drives the transmission rod 43 to rotate under the action of the central be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com