Four-quadrant hydraulic pump performance optimization test system and method

A testing system and hydraulic pump technology, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve problems such as difficulty in testing, inability to simulate negative loads, and inability to quantify the size of different negative loads. Achieve the effect of making up for a single function and optimizing parameter matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

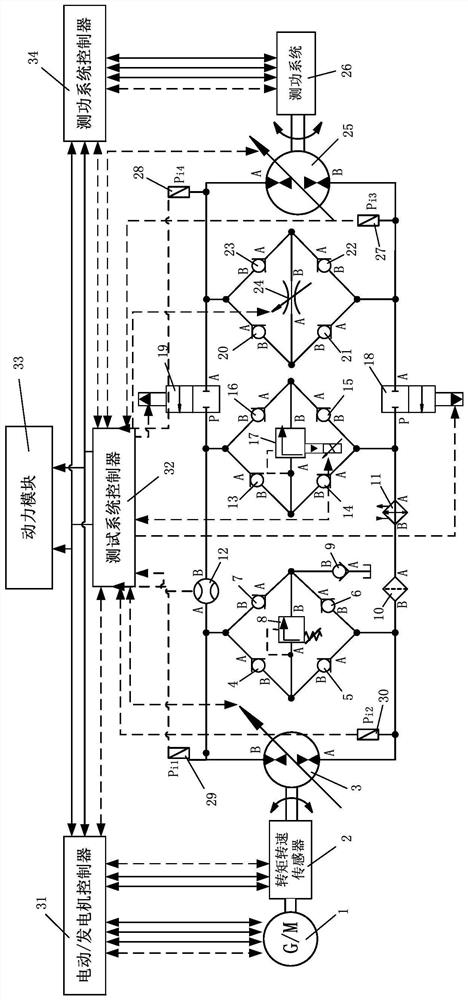

[0039] Please refer to figure 1 As shown, the present invention provides a four-quadrant hydraulic pump performance optimization test system, the system includes a motor / generator (1), a torque speed sensor (2), a first tested pump (3), a first unidirectional Valve (4), second one-way valve (5), third one-way valve (6), fourth one-way valve (7), safety valve (8), fifth one-way valve (9), filter ( 10), cooler (11), flow sensor (12), sixth one-way valve (13), seventh one-way valve (14), eighth one-way valve (15), ninth one-way valve (16) , Proportional overflow valve (17), first two-position two-way electromagnetic reversing valve (18), second two-position two-way electromagnetic reversing valve (19), tenth one-way valve (20), eleventh one-way valve Directional valve (21), twelfth one-way valve (22), thirteenth one-way valve (23), proportional throttle valve (24), second tested pump (25), dynamometer system (26), The first pressure sensor (27), the second pressure sensor (28),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com