Sealing bolt, forming die and forming process

A technology for sealing bolts and bolts, which is applied in the direction of bolts, screws, manufacturing tools, etc., can solve the problems that the sealing performance cannot be guaranteed, and achieve the effects of prolonging the reuse rate, reducing the difficulty of forming, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment, the invention is further described:

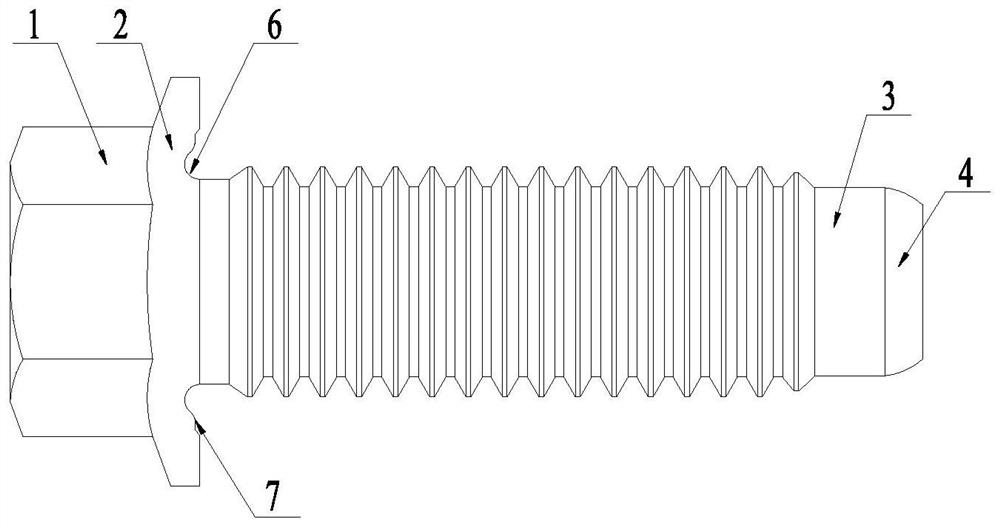

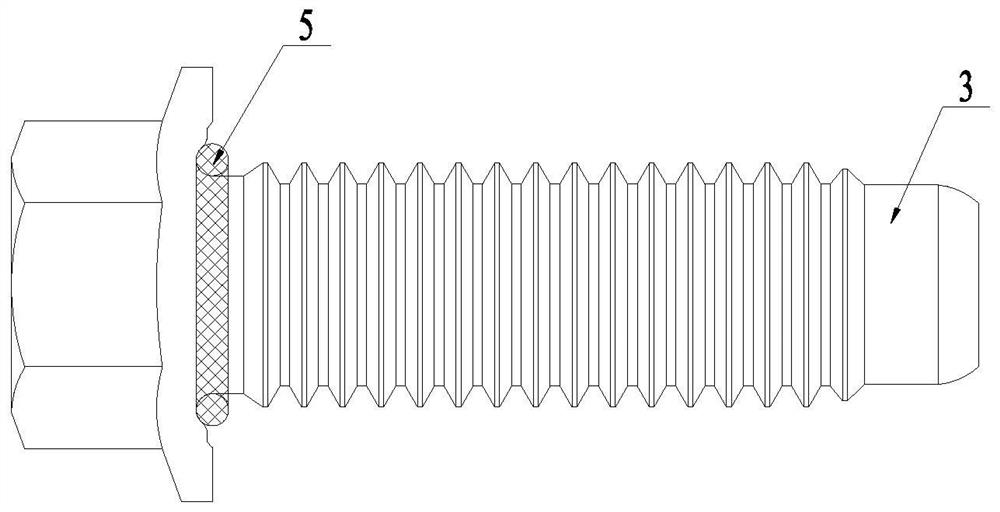

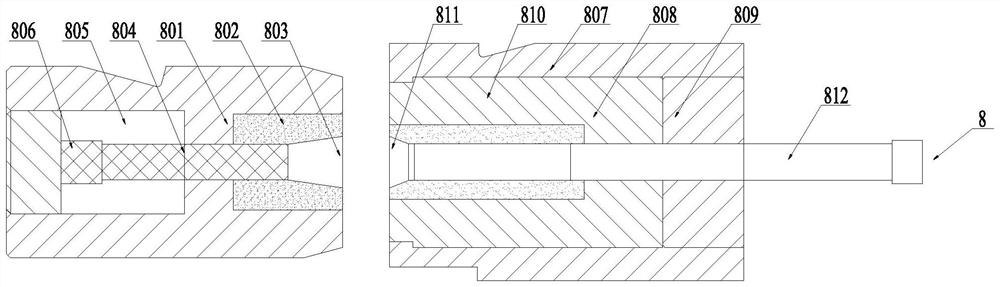

[0039] like figure 1 — figure 2 As shown, a sealing bolt includes an integrally formed head and a stem, the head includes an integrally connected bolt head 1 and a flange 2, and the bolt head 1 has six tightening surfaces evenly distributed along the outer periphery. The end of the bolt head 1 is fixedly connected to the flange plate 2, and the middle part of the other end of the flange plate 2 is connected with a rod portion, and the rod portion includes a screw rod 3 and a double inverted screw rod arranged in a step-like distribution at the tail end of the screw rod 3. Angle 4, the surface of the screw 3 is evenly distributed with threads along the outer peripheral direction, and the upper and lower ends of the connection between the flange 2 and the screw 3 are provided with a groove for accommodating the O-ring 5, and the groove includes a normal The inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com