Clutch self-locking ratchet wheel and machining device thereof

A processing device and clutch technology, which is applied in metal processing, metal processing equipment, couplings, etc., can solve the problems of switching failure, ratchet collision and breaking, etc., to achieve enhanced reliability, reduced collision strength, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

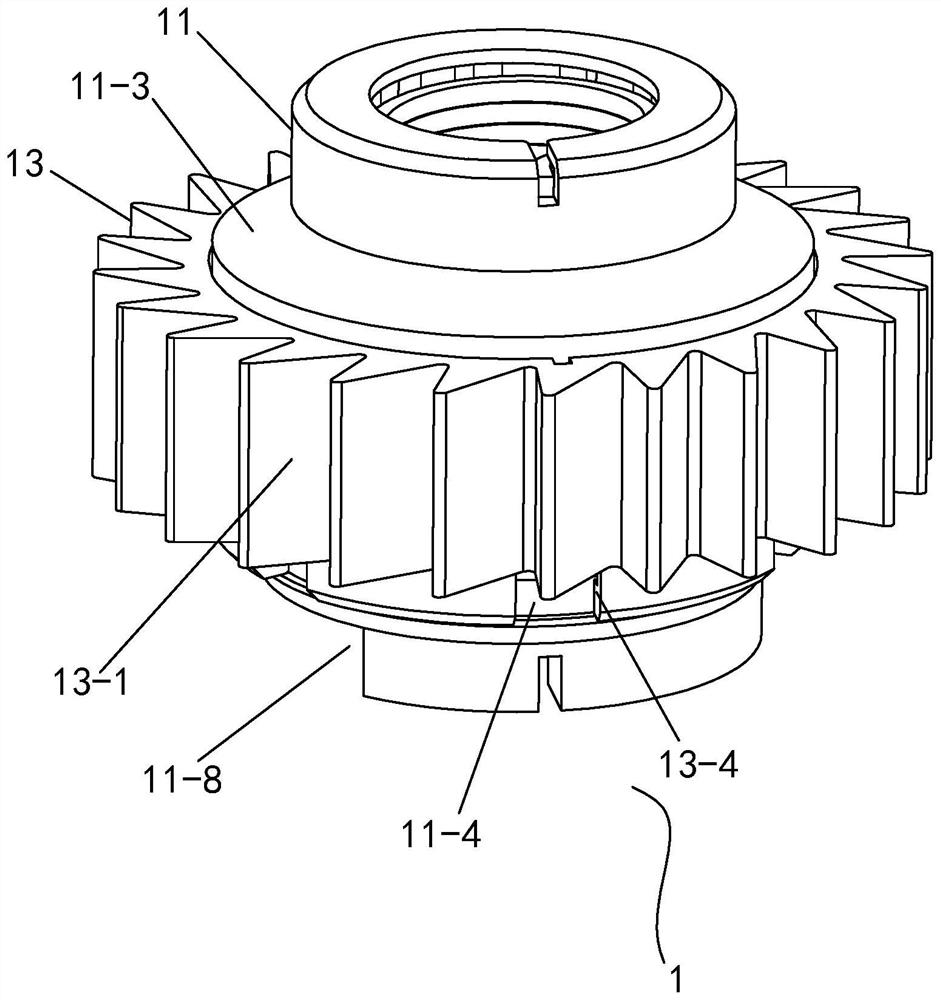

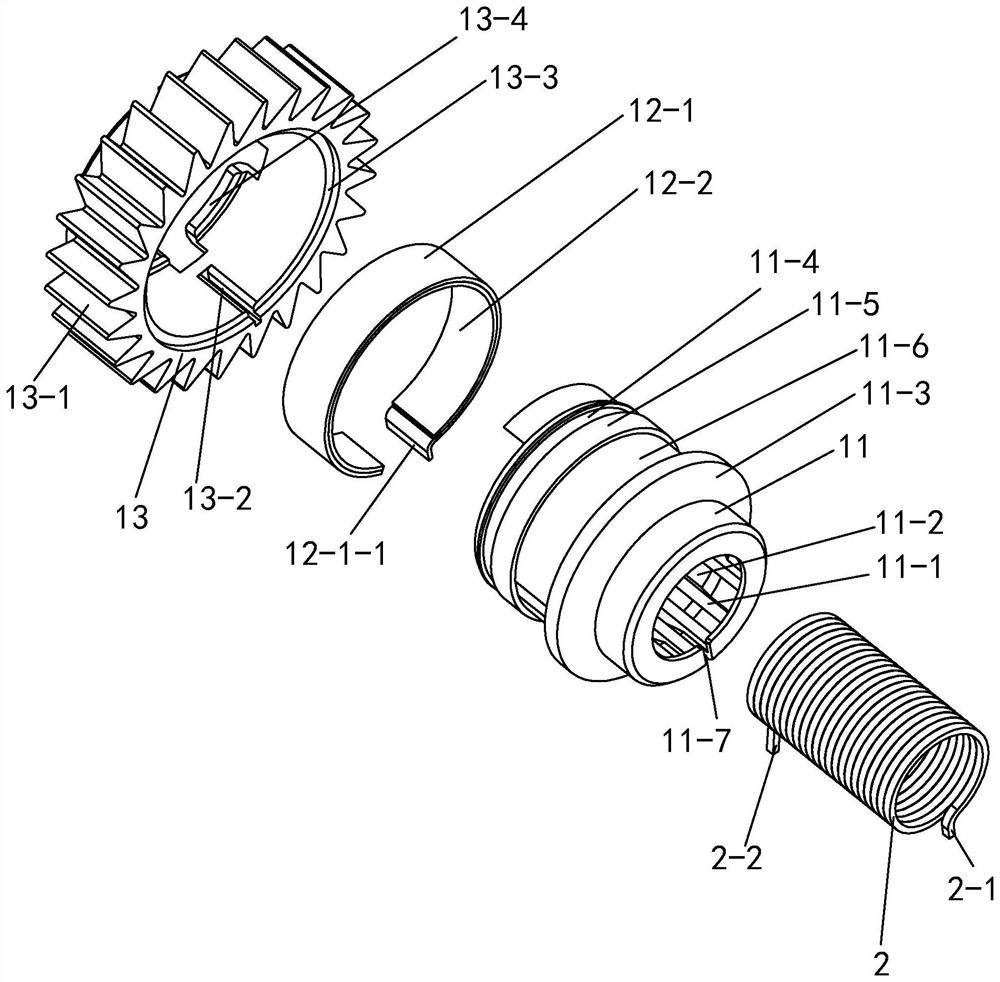

[0022] This example figure 1 and 2 Shown is a clutch self-locking ratchet, including a shaft sleeve 11, a self-locking coil spring 12 and a ratchet sleeve 13. A plurality of raised ribs 11-1 are arranged on the inner wall of the shaft sleeve 11, and between the raised ribs 11-1 are Oil storage tank 11-2, ratchet 13-1 is arranged on the outer wall of ratchet sleeve 13; The sleeve 13 and the shaft sleeve 11 are axially limited, and the control end 12-1-1 of the self-locking coil spring 12 is embedded in the ring groove 13-2 on the inner wall of the ratchet sleeve 13, and the locking direction of the self-locking coil spring 12 is in line with the ratchet teeth The reverse direction of 13-1 is the same.

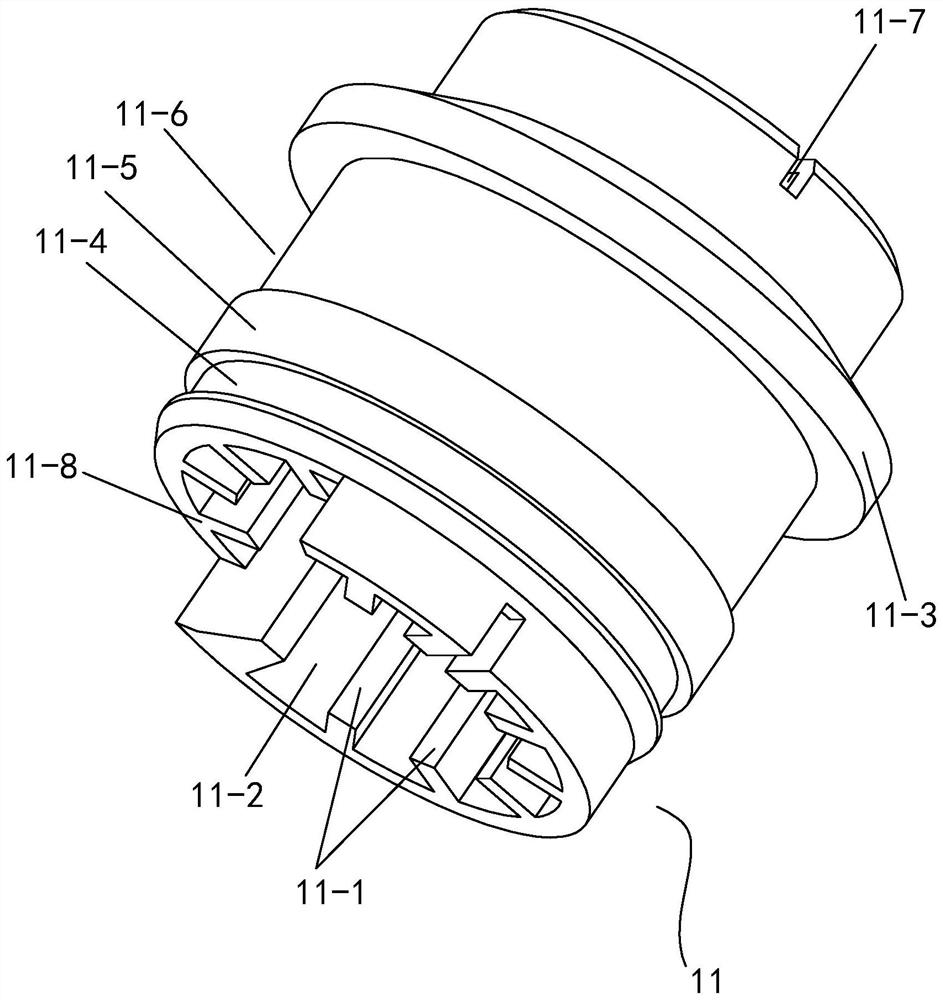

[0023] In this embodiment, the bushing 11 is as image 3 As shown, the outer wall is provided with a protruding ring 11-3 and an annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com