Ball valve capable of reducing impact effect

An impact action, ball valve technology, applied to valve devices, cocks including cut-off devices, mechanical equipment, etc., can solve problems such as damage to the opening and closing parts, the reduction of the ball valve's effect on fluid regulation and control, and the low work efficiency. It is not easy to achieve Damage, increased protection, reduced impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

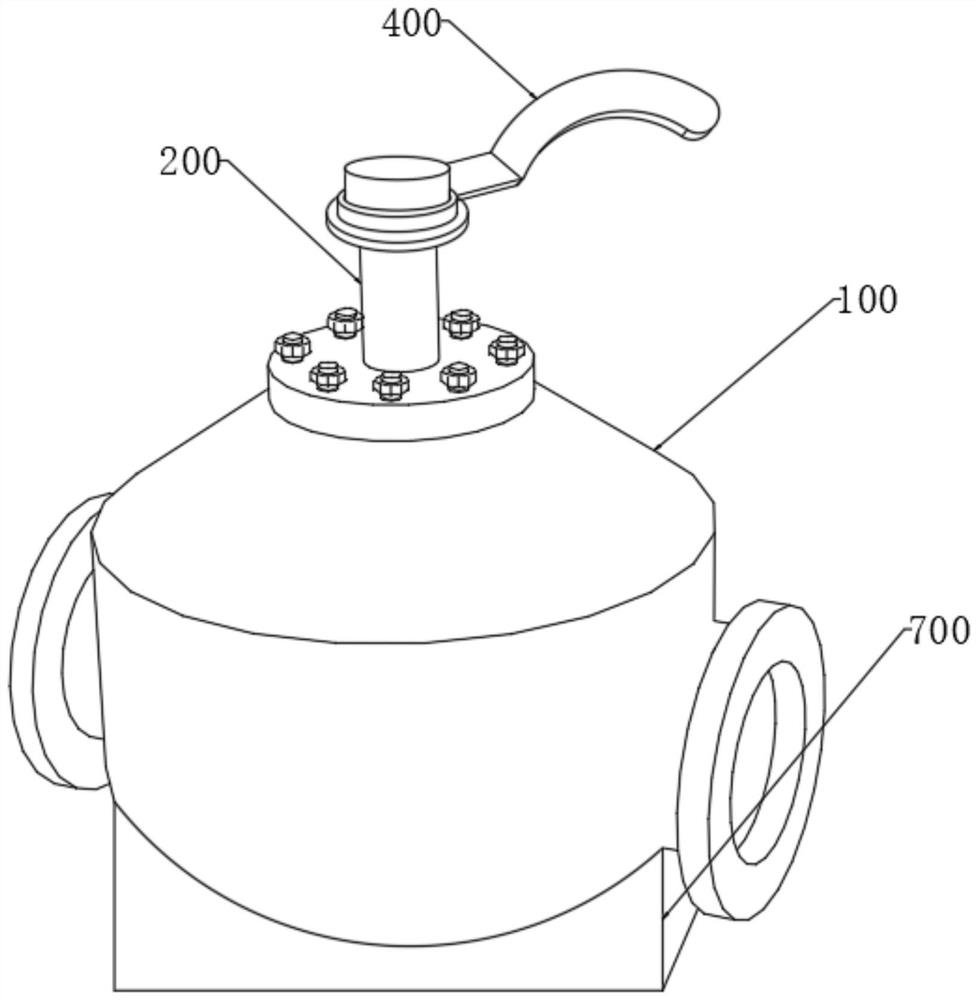

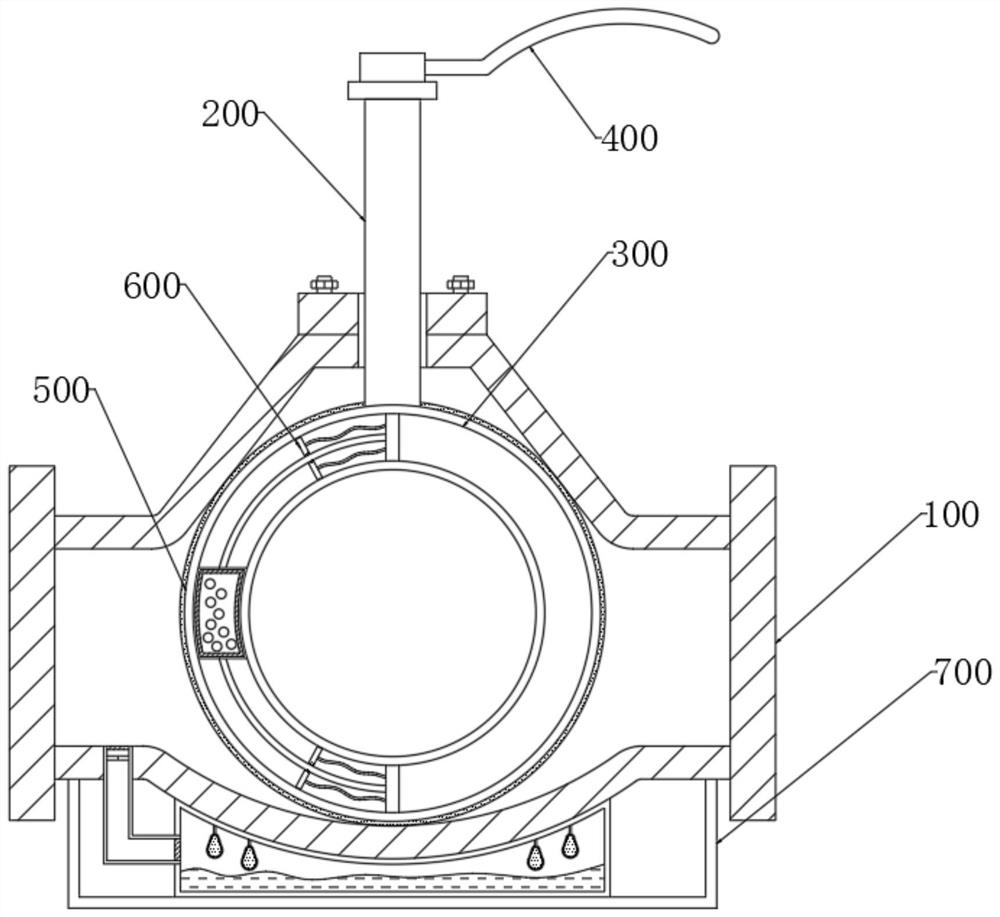

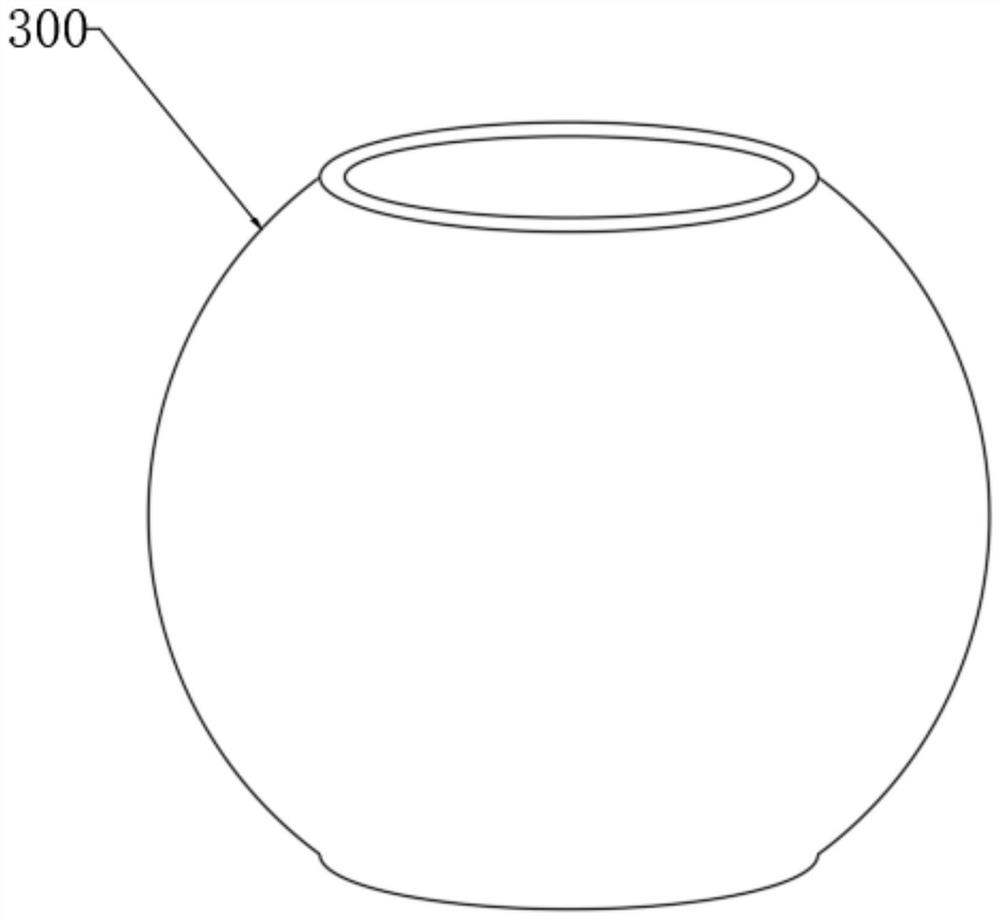

[0042] see Figure 1-8 , a ball valve for reducing the impact effect, comprising a ball valve body 100, a ball valve body 300 is arranged inside the ball valve body 100, a valve stem 200 is rotatably connected to the inside of the ball valve body 100, and the lower end of the valve stem 200 is fixedly connected with the upper end of the valve ball body 300 , the upper side of the ball valve body 100 is provided with a handle 400, the upper end of the valve rod 200 is fixedly connected with the handle 400, the outer end of the valve ball 300 is provided with a buffer dispersion mechanism 500, and the inside of the valve ball 300 is provided with a facing pressure mechanism 600 , the lower end of the ball valve body 100 is equipped with a pneumatic dispersing mechanism 700. In this solution, when the fluid impacts on the valve ball body 300, the impact force received by the valve ball body 300 is dispersed by buffering the dispersion layer of the dispersion mechanism 500, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com