Environment-friendly energy-saving central air conditioner

A central air-conditioning, energy-saving technology, applied in the direction of space heating and ventilation details, heating methods, lighting and heating equipment, etc., can solve the problem that the air outlet mechanism cannot swing out the air, so as to reduce the multi-layer design and expand the air outlet. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

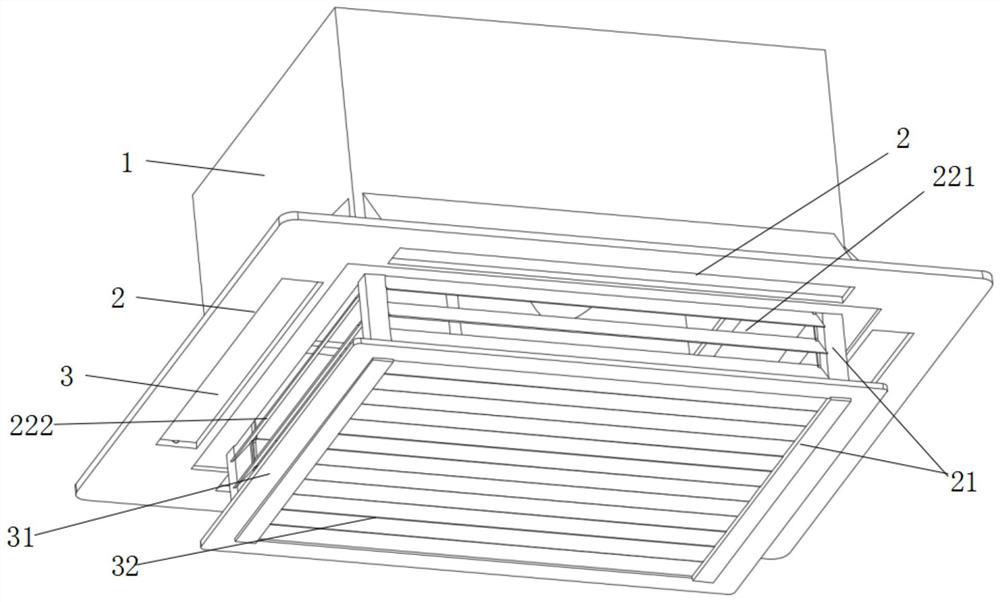

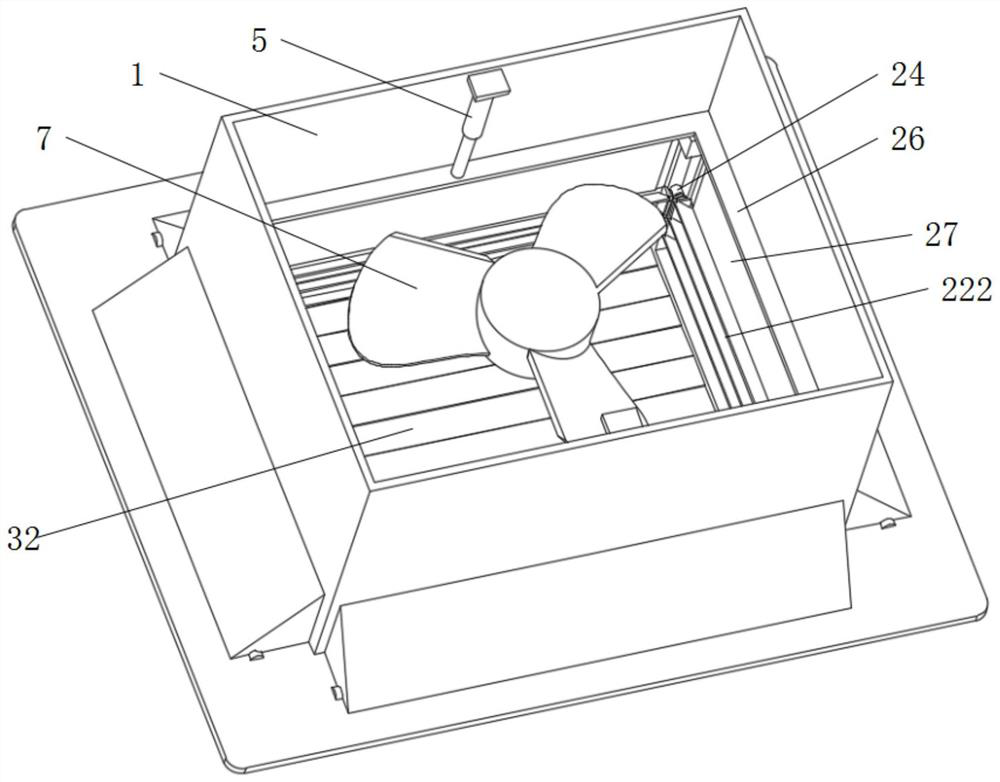

[0029] Such as Figure 1 to Figure 10 As shown, the present invention provides an environment-friendly and energy-saving central air conditioner, comprising an outdoor unit and an air supply pipe, the air supply pipe is connected with the external unit, and also includes an air outlet box 1, which is communicated with the air supply pipe; Slidingly, there is a lifting grille mechanism for swinging air in the horizontal direction, and a vertical grille mechanism for swinging air in the vertical direction is provided at the bottom of the horizontal grille mechanism; The air outlet 2 is rotated with a lateral swing leaf 3, which is connected with the lifting grille mechanism through the telescopic pull rod 4; The swing blade 3 opens and closes the side air outlet 2 through the telescopic pull rod 4, so that when the lifting grille mechanism enters the air outlet box 1, the side air outlet 2 can be opened to combine with the vertical grille mechanism to discharge air; When the gr...

Embodiment 2

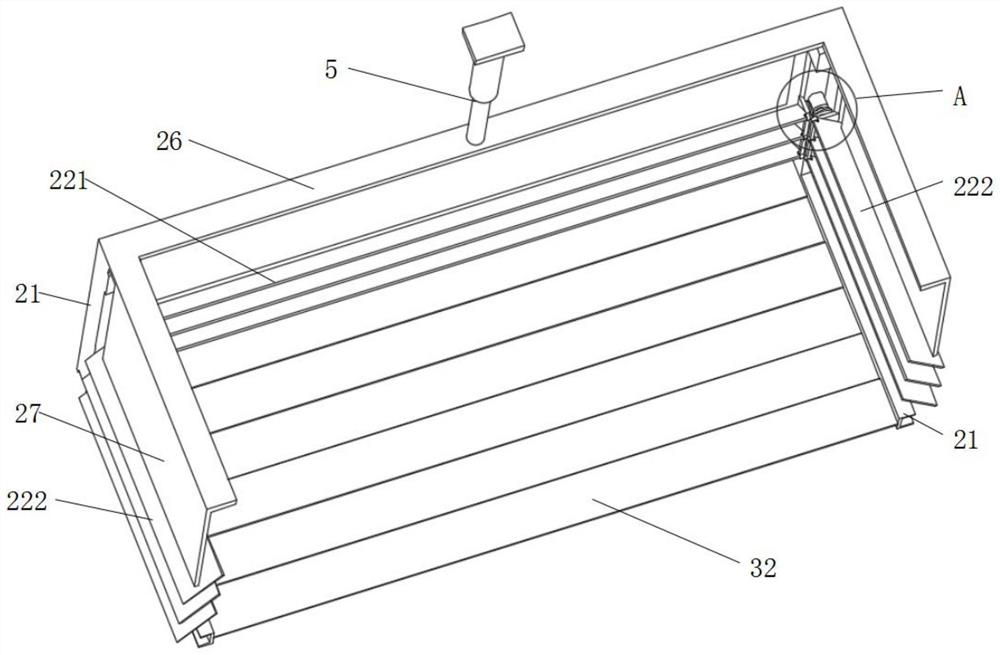

[0035] Such as Figure 4 As shown, in combination with the technical solution of Embodiment 1, in this embodiment, the linkage mechanism 23 includes a first bevel gear 231 and a second bevel gear 232, and the horizontal swing blade 22 includes a horizontal horizontal swing blade 221 and a longitudinal horizontal swing blade 222. A bevel gear 231 is respectively connected to both ends of the horizontal horizontal swing blade 221, a second bevel gear 232 is respectively connected to both ends of the longitudinal horizontal swing blade 222, the output end of the first motor 24 is coaxially connected to the second bevel gear 232, The first bevel gear 231 and the second bevel gear 232 are meshed for transmission, so that the horizontal horizontal swing leaves 221 and the longitudinal horizontal swing leaves 222 form a rectangular frame 26 structure for linkage, so as to realize the synchronous rotation and swing of four groups of horizontal swing leaves 22 Wind; by setting the mesh...

Embodiment 3

[0037] Such as Figure 5 to Figure 8 As shown, in combination with the technical solution of Embodiment 2, in this embodiment, the vertical grid mechanism includes a frame plate 31, a vertical swing leaf 32, a second linkage rod 33 and a second motor 34, and the frame plate 31 is connected to the lifting frame 21 end, the vertical swing blade 32 is rotated and arranged in the frame plate 31, and the two ends of the vertical swing blade 32 are provided with rotating pieces 36, and the rotating pieces 36 on the multiple vertical swing blades 32 pass through the second linkage rod 33 is hinged; the second motor 34 is located in the lifting frame 21, and the end of the vertical swing leaf 32 on one side of the end of the frame plate 31 is provided with a third bevel gear 35, and the second motor 34 connects the third bevel gear through the bevel gear. The gear 35 is meshed and driven to drive the third bevel gear 35 to rotate through the second motor 34 to make the vertical pendul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com