Automatic rapid cooling system, cold bin and automatic rapid cooling method

A quick-cooling and automatic technology, applied in coolers, refrigerated rooms, household refrigeration devices, etc., can solve the problems of insignificant changes in gas field flow, small number of placements, low cooling efficiency, etc., to improve the efficiency of rapid cooling and rapid cooling. ability, the effect of speeding up the flow through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and examples. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

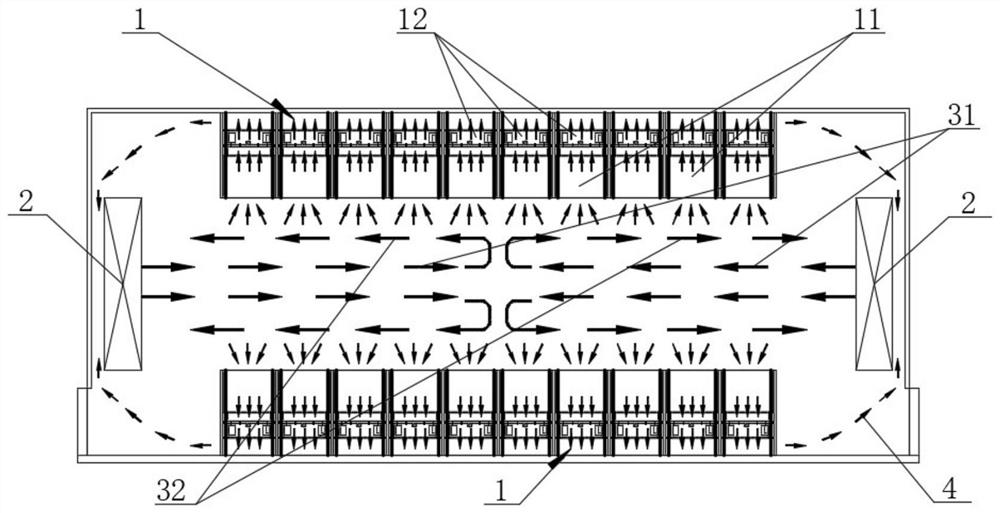

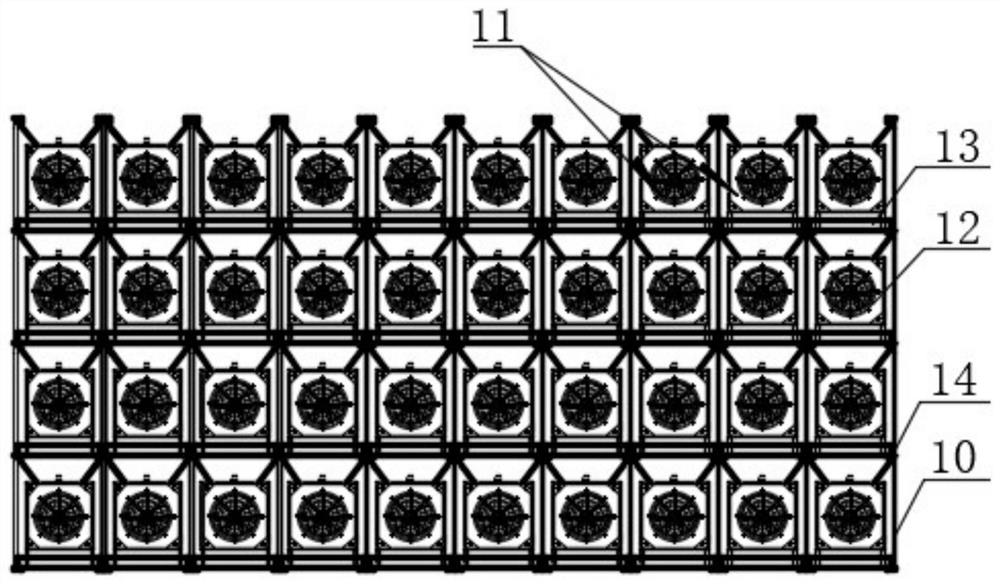

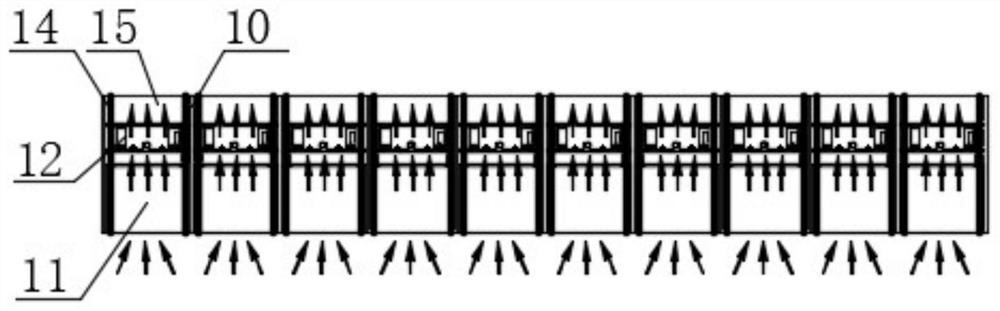

[0073] like Figure 1 to Figure 9 As shown, the embodiment of the present invention provides an automatic rapid cooling system, and based on the automatic rapid cooling system, an automatic rapid cooling method and a cold storage are proposed.

[0074] like figure 1 As shown, the automatic quick-cooling system according to the embodiment of the present invention includes at least one pair of quick-cooling shelves 1 and at least one pair of refrigeration units 2 . Wherein, each pair of quick-cooling shelves 1 are arranged opposite to each other, so as to leave an air flow passage between each pair of quick-cooling shelves 1 . At least one pair of refrigeration units 2 are respectively installed at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com