Material strength detection device for bridge construction

A technology for strength testing and bridge construction. It is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and analyzing materials. It can solve problems such as inconvenient and safe, and facilitate power supply heat dissipation, fast and safe placement or removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Through the electromagnet guide rail 3, the metal sliding seat 4, and the workbench 5, the technical problem that the way of placing or taking out the concrete test block in the prior art is not simple and safe is solved, and the fast and safe placing or taking out of the concrete test block is realized. technical effect.

[0027] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

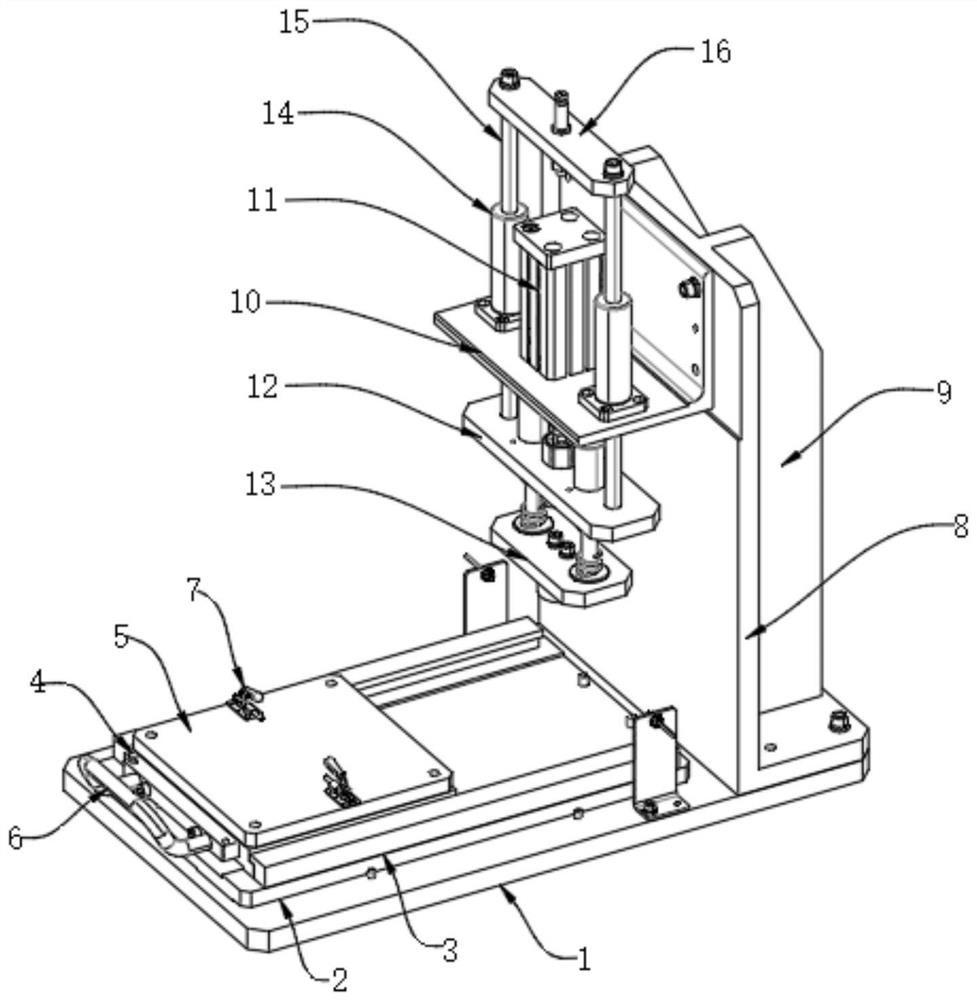

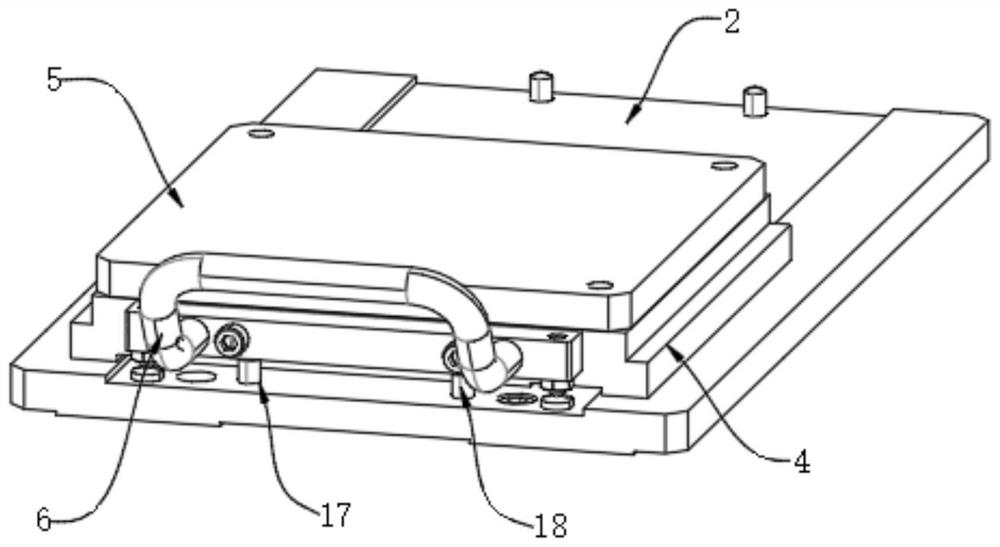

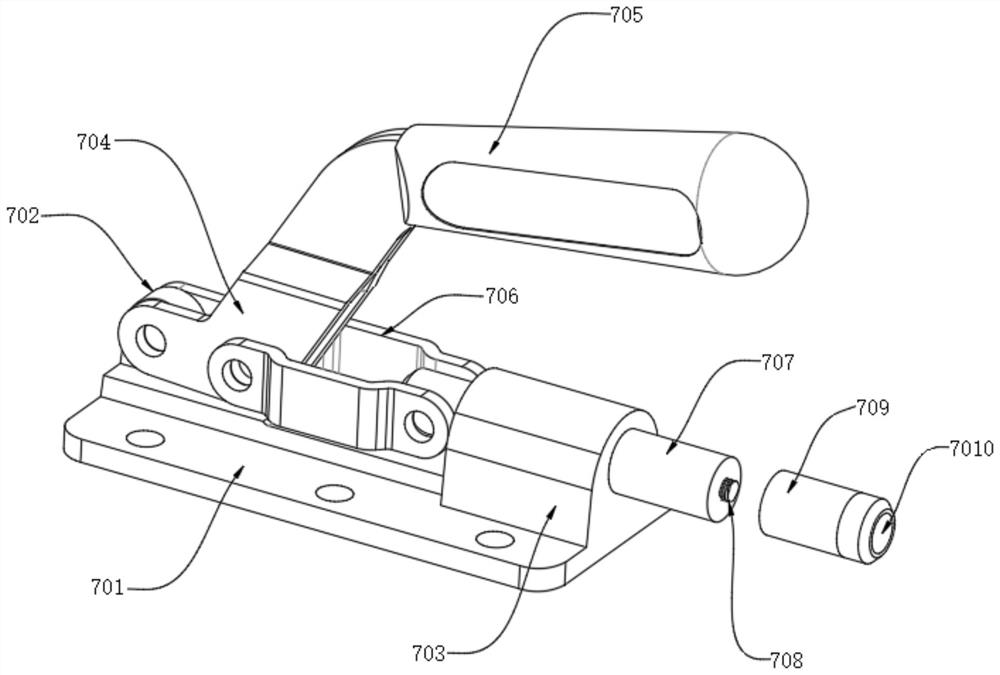

[0028] see Figure 1~6 , in the embodiment of the present application, a material strength detection device for bridge construction includes a base plate 1, an insulating plate 2 is fixedly connected to the top surface of the bottom plate 1, and electromagnets are symmetrically fixedly connected to both sides of the top surface of the insulating plate 2 The guide rail 3 is movably connected with a metal slide 4 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com