Device and method for detecting surface defects of planar optical element

A technology of optical components and detection devices, which is used in measurement devices, optical testing of defects/defects, material analysis by optical means, etc., can solve the problem that the detection results are not intuitive, the detection process is cumbersome, and the specific location and size of defects cannot be accurately described. size and other problems, to eliminate power instability, improve detection accuracy, and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

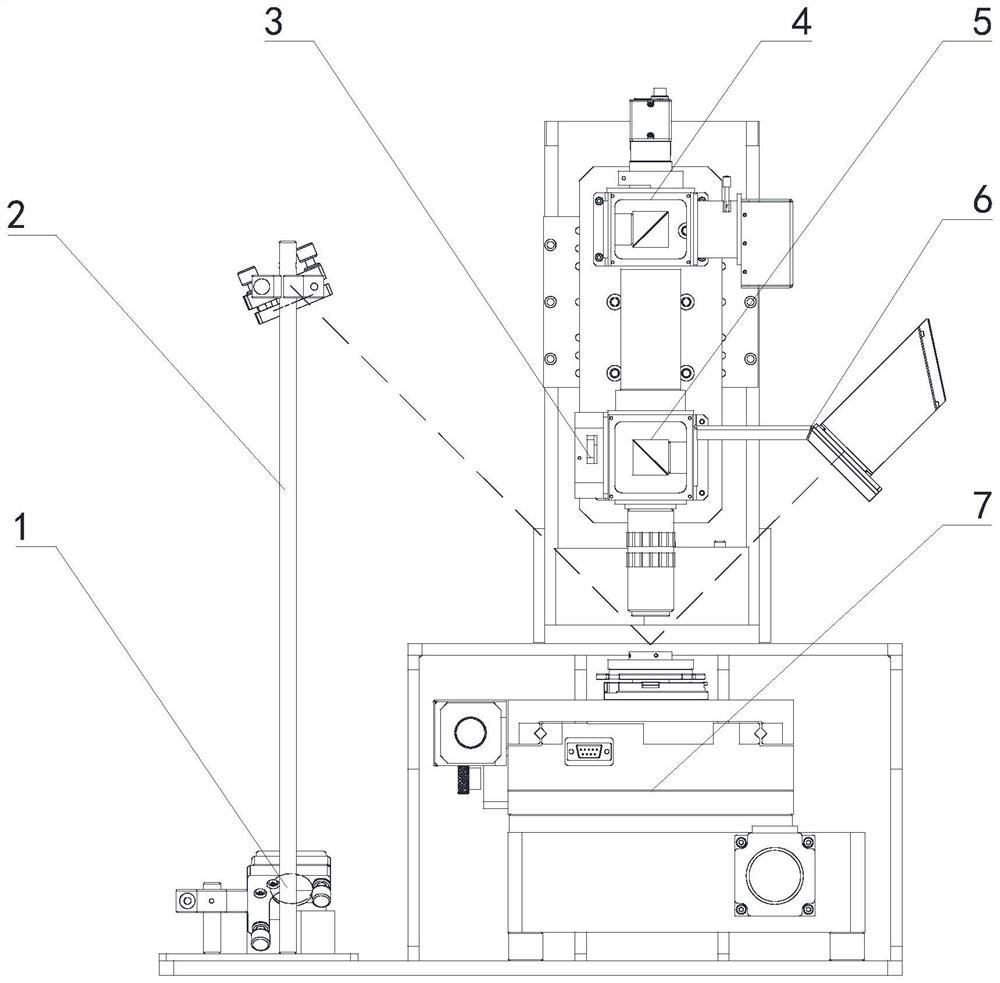

[0065] In this example, if figure 1 As shown, a surface defect detection device for a planar optical element includes: a laser 1, a beam deflection module 2, a focus measurement module 3, a main detection module 4, a main optical path module 5, an optical trap module 6, and a motion control module 7;

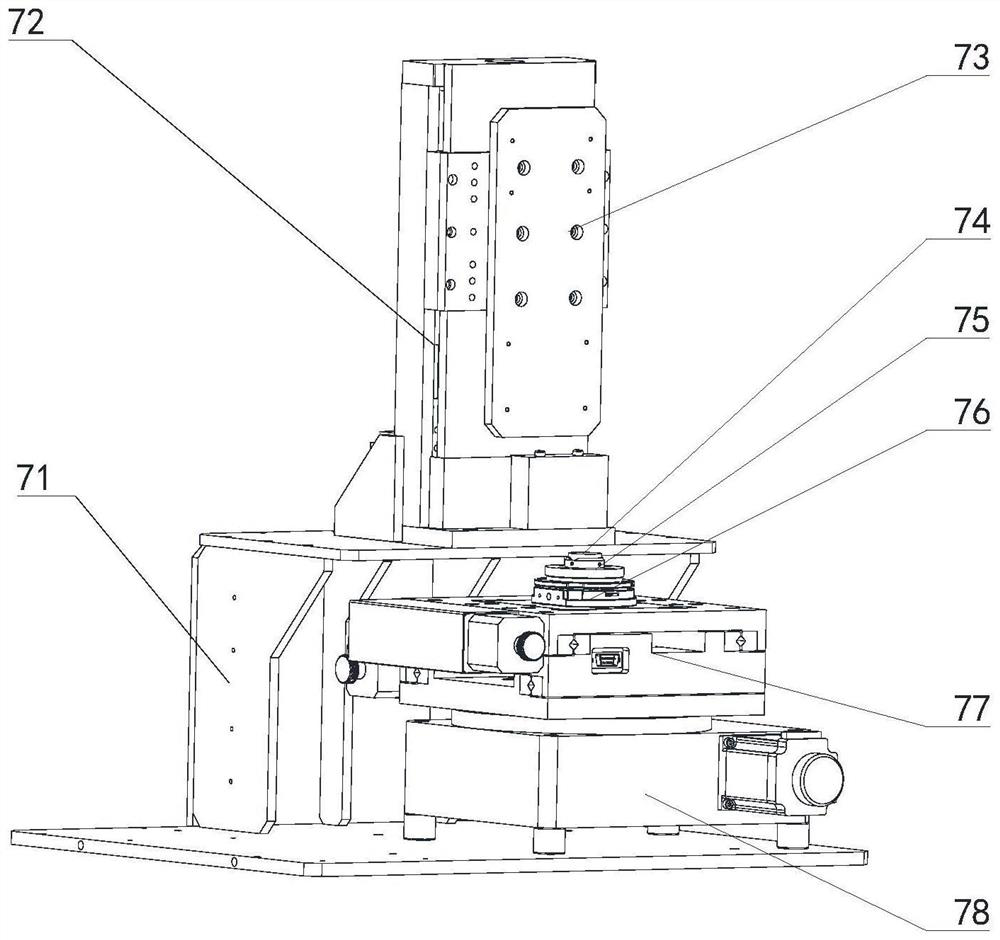

[0066] Such as figure 2 As shown; the motion control module 7 includes: a support 71, a vertical displacement stage 72, a substrate 73, a sample holder 75, an inclined stage 76, a two-dimensional displacement stage 77, and a rotary stage 78;

[0067] The sample 74 to be tested is arranged on the sample holder 75 and fixed on the tilting table 76, the tilting table 76 is fixed on the two-dimensional displacement table 77, and the two-dimensional displacement table 77 is fixed on the rotary table 78; the rotary table 78 is fixed on the support 71 ;

[0068] The base plate 73 is fixed on the vertical displacement platform 72, and the vertical displacement platform 72 is also fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com