Electronic detonator shock resistance evaluation and optimization design method

A technology of impact resistance and electronic detonator, which is applied in design optimization/simulation, offensive equipment, electrical digital data processing, etc., can solve problems that restrict the quality of electronic detonators, shorten the development cycle, speed up the development progress, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

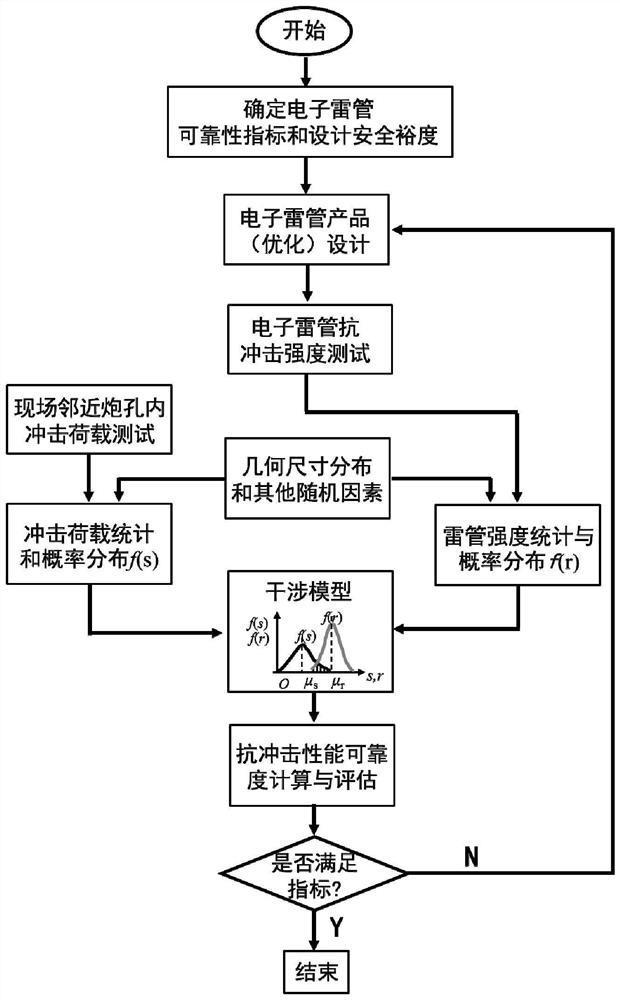

[0050] Example 1, see figure 1 , figure 2 , image 3 , a method for evaluating the impact resistance of an electronic detonator, comprising the following steps;

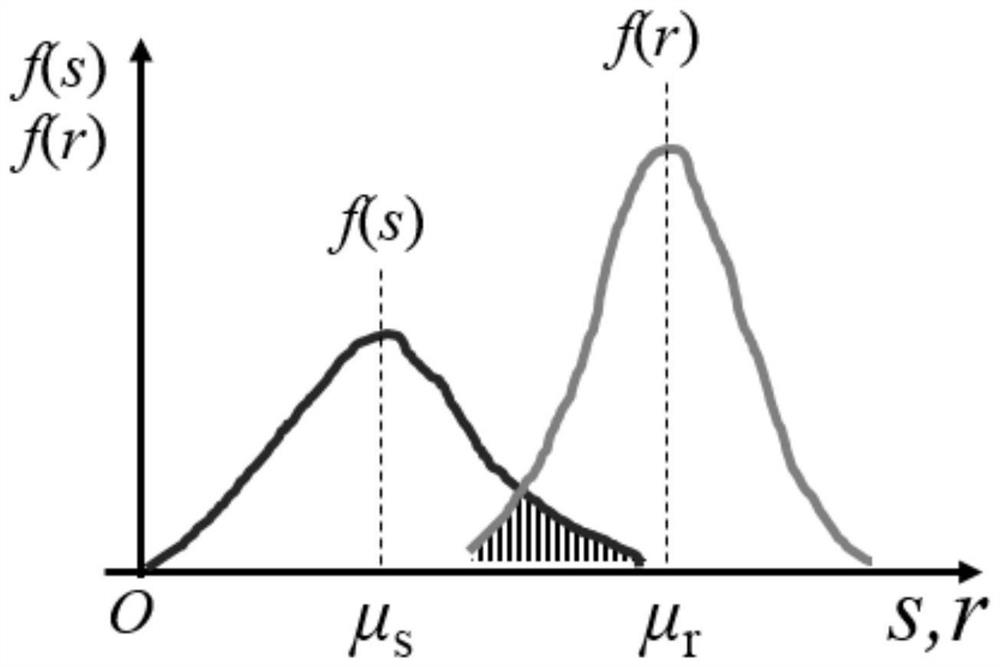

[0051] S1, impact strength test: determine the critical load value of detonator impact failure by impact simulation test, carry out statistical analysis to test data, obtain the probability distribution function g(r)=(r) of the impact resistance r of this batch of electronic detonators 1 , r 2 ,...,r n ); where, n is the number of impact simulation tests;

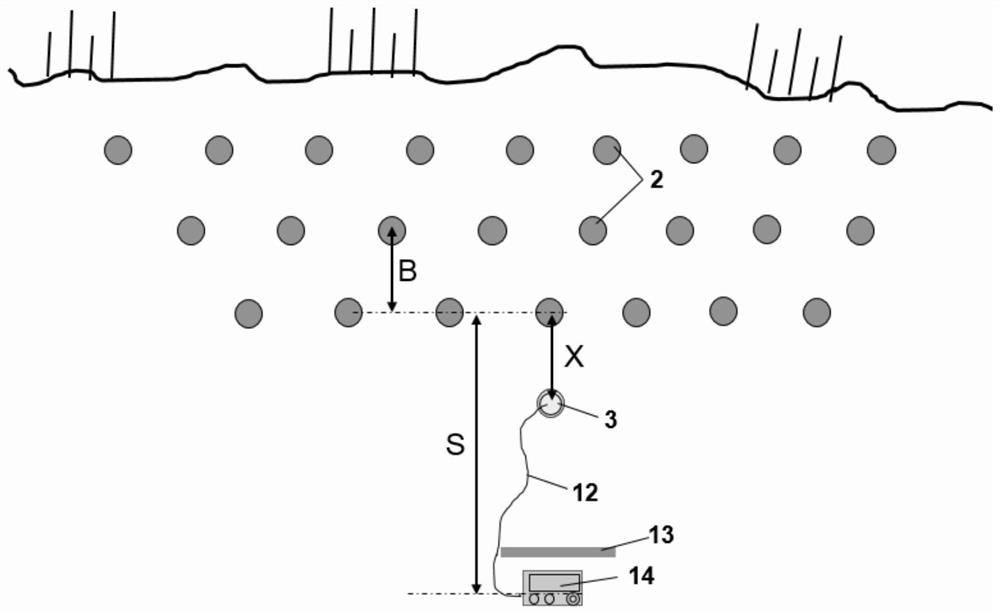

[0052] S2. On-site impact load test and statistical analysis: test the impact load in the test hole through multiple on-site test holes, determine the peak impact load of the electronic detonator in the test hole, and perform statistical analysis on the test data to obtain the test hole in the on-site environment The probability distribution function h(s)=h(s) of the peak value of the internal impact load 1 ,s 2 ,...,s m ); where, m is the number of impac...

Embodiment 2

[0068] Example 2, see figure 1 , figure 2 and image 3 , an optimal design method for an electronic detonator, comprising the following steps in sequence:

[0069] The first step, preliminary design: conduct preliminary design of electronic detonator structure based on the determined reliability index β and design safety margin Nc;

[0070] The second step, safety and reliability evaluation: apply the electronic detonator shock resistance performance evaluation method of embodiment 1, carry out safety and reliability evaluation to the electronic detonator produced by the design standard, and based on failure probability F and safety margin N Quantitative data to give the evaluation results of "pass" or "failure";

[0071] The third step is to determine the follow-up work based on the evaluation result: when the evaluation result is "qualified", execute the fifth or sixth step; when the evaluation result is "unqualified", execute the fourth step;

[0072] The fourth step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com