Integrated suspension electromagnet, linear motor and maglev train

A technology for levitation electromagnets and maglev trains, applied in electromagnets, electric vehicles, superconducting magnets/coils, etc., can solve problems such as burnout, heat generation, and work heat that affect the improvement of carrying capacity, and achieve the benefits of control, reduction of temperature rise, The effect of ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

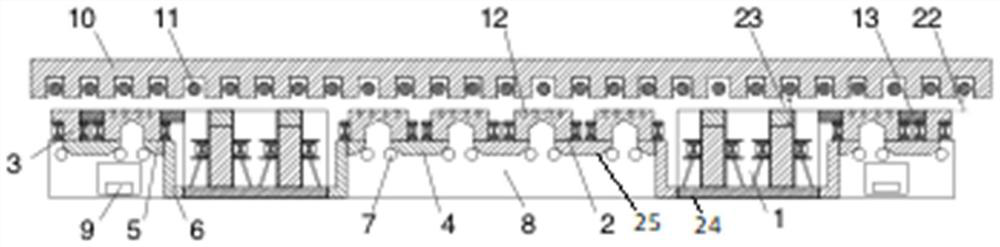

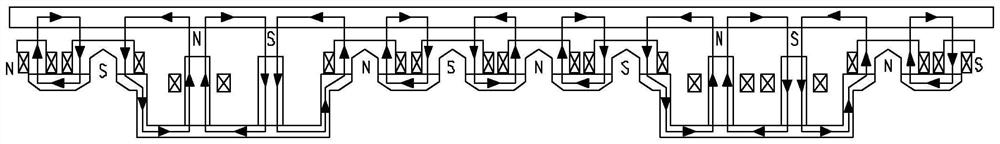

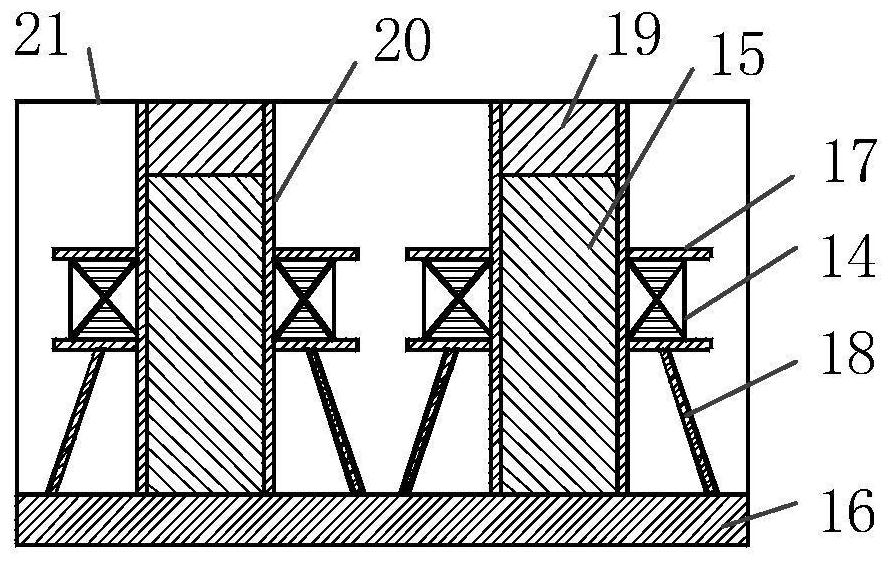

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The existing constant-conduction levitation electromagnet technology can meet the current running speed requirements of high-speed maglev trains. As the speed further increases, the vertical dynamic load of the vehicle will intensify. The levitation electromagnet with constant conduction can improve the levitation ability by increasing the current, but increasing the current will cause serious heating and there is a risk of burning.

[0034]Based on this, the embodiment of the present application provides a superconducting and normally conducting integrated levitation electromagnet, including a plurality of normally conducting magnets and a plurality of superconducting magnets fixed on the box girder, and the normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com