Preventing microbial growth in heat exchangers

A technology of heat exchangers and microorganisms, applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of increased production costs and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

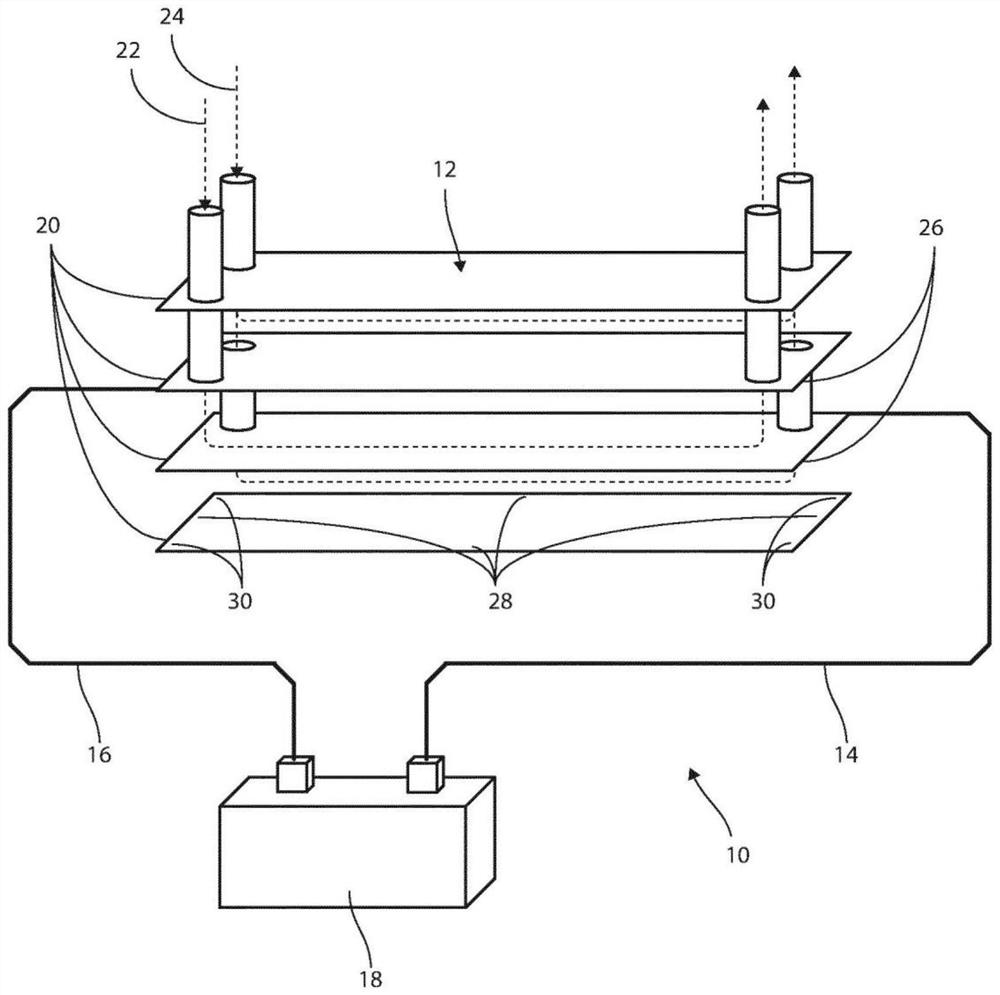

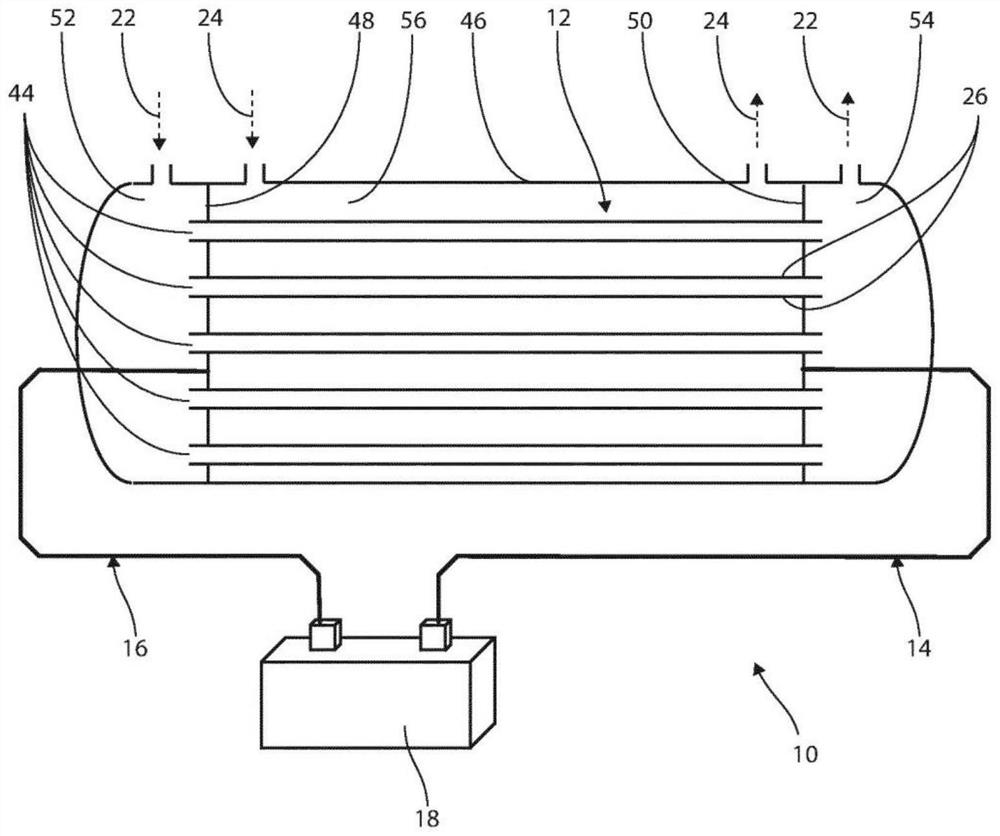

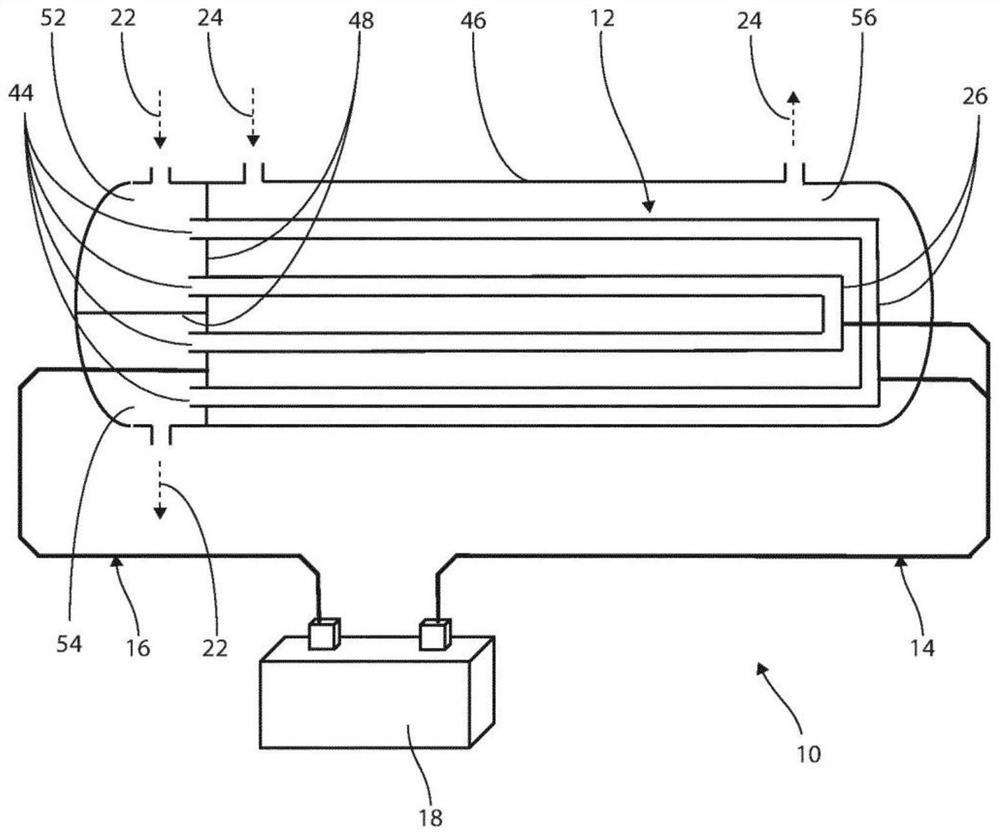

[0057] An embodiment of a heat exchanger assembly 10 is schematically shown in figure 1 middle. It consists of a heat exchanger 12 , a first electrical connector 14 , a second electrical connector 16 and a power source 18 . The heat exchanger 14 is a plate heat exchanger with four parallel plates 20 . The plates are rectangular and stainless steel. This means that each panel 20 has four sides 28 and four corners 3, as figure 1 shown.

[0058] The plates 20 are joined at edges (not shown) and form three channels in which the first fluid 22 and the second fluid 24 pass as figure 1 The flow indicated by the dotted line in . The first fluid 22 is sea water and the second fluid 24 is fresh water. The flow of the first fluid 22 and the second fluid 24 is created or provided by a pump (not shown). The flow direction of the first fluid 22 and the second fluid 24 is determined by figure 1 Indicated by arrows in , which show parallel flow. In alternative embodiments, the flow m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com