Green fabricated concrete prefabricated component and preparation method thereof

A prefabricated component and concrete technology, applied in building components, manufacturing tools, supply devices, etc., can solve the problems of inability to meet inspection and acceptance, increased transportation costs, increased mold costs, etc., to improve the overall preparation quality, and facilitate stacking and transportation. , the effect of reducing the space demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

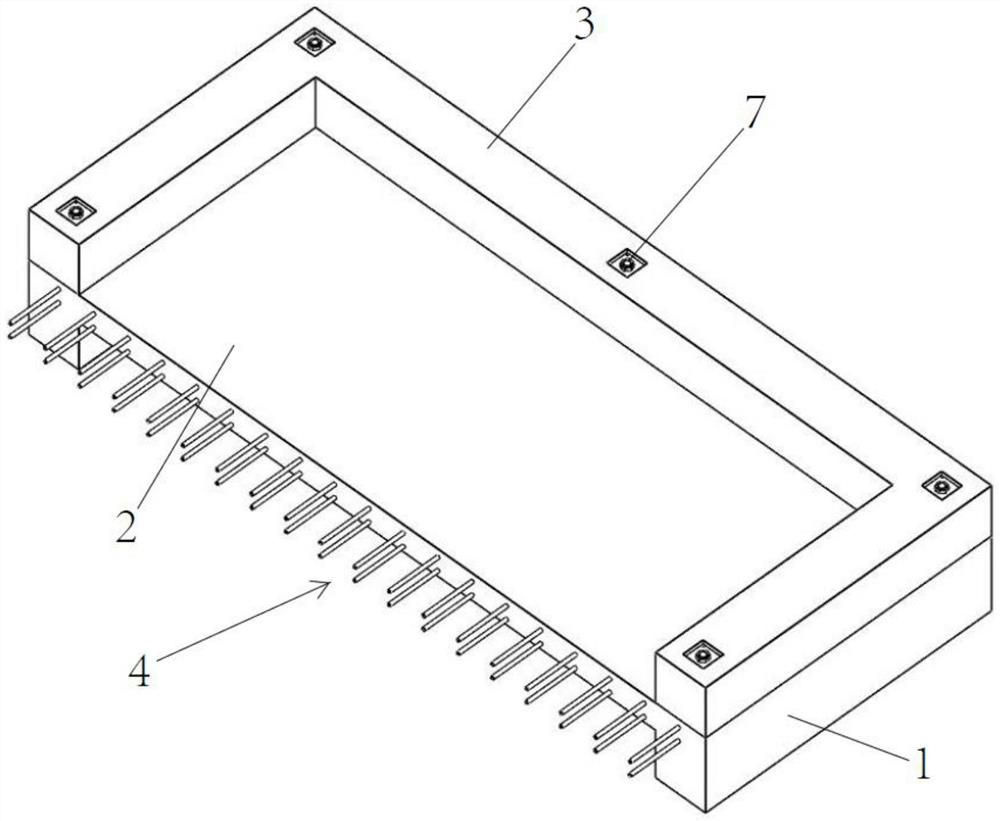

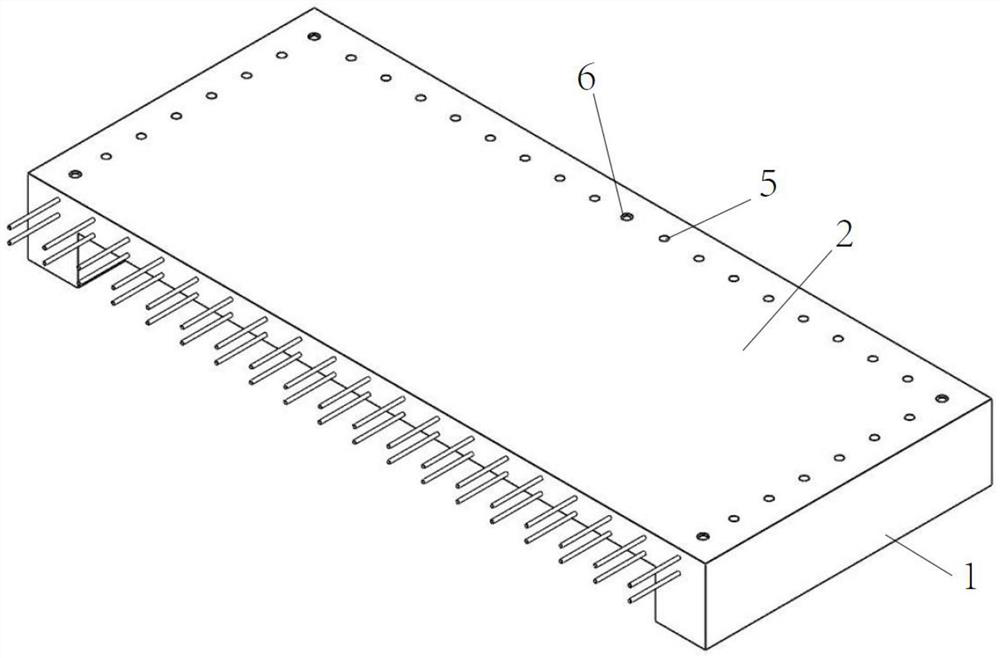

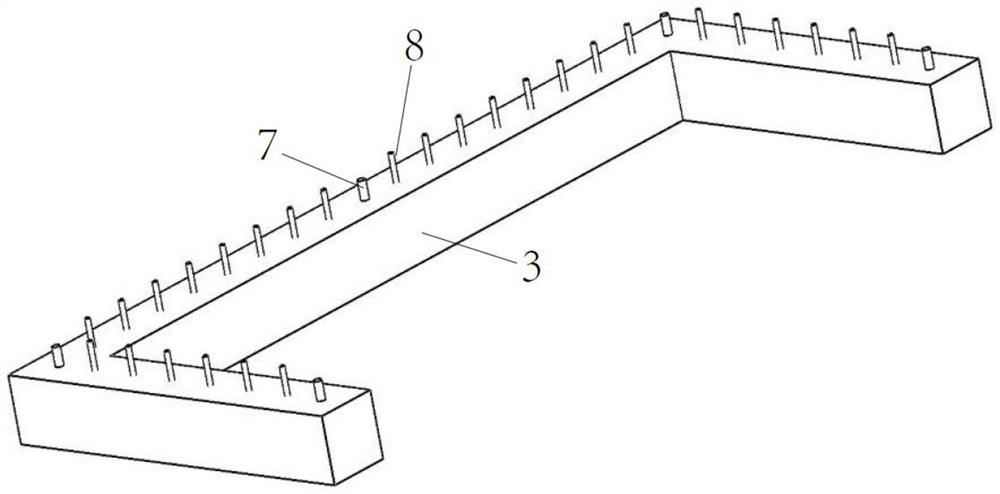

[0033] refer to Figure 1 to Figure 4 As shown, an embodiment of the green prefabricated concrete component of the present invention includes a lower side beam 1, a balcony slab 2 and an upper side beam 3, and the balcony slab and the lower side beam are a structure formed by integral pouring, which is a bottom Module 4, the surface of the balcony slab is set flush with the surface of the lower side beam, which is convenient for preparation and stacking. The surface of the lower side beam is provided with a reinforcement hole 5 and a lock hole 6, and an internal thread sleeve is embedded in the lock hole. For matching connection, the upper side beam corresponding to the internal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com