High-precision duct piece clamping and positioning mechanism of ring type duct piece erector

A segment assembly machine, clamping and positioning technology, applied in shaft equipment, wellbore lining, mining equipment, etc., can solve problems such as difficult alignment, large segment installation deviation, etc., to reduce installation deviation, speed up project progress, control high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

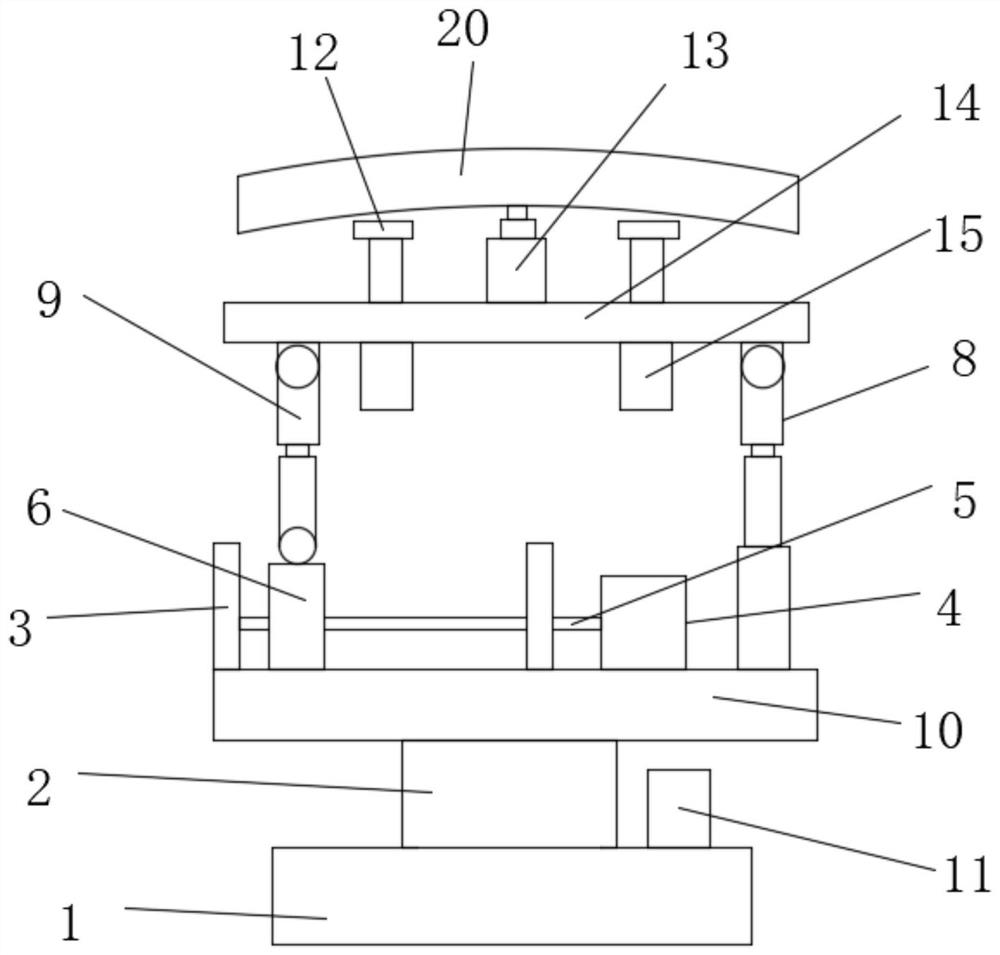

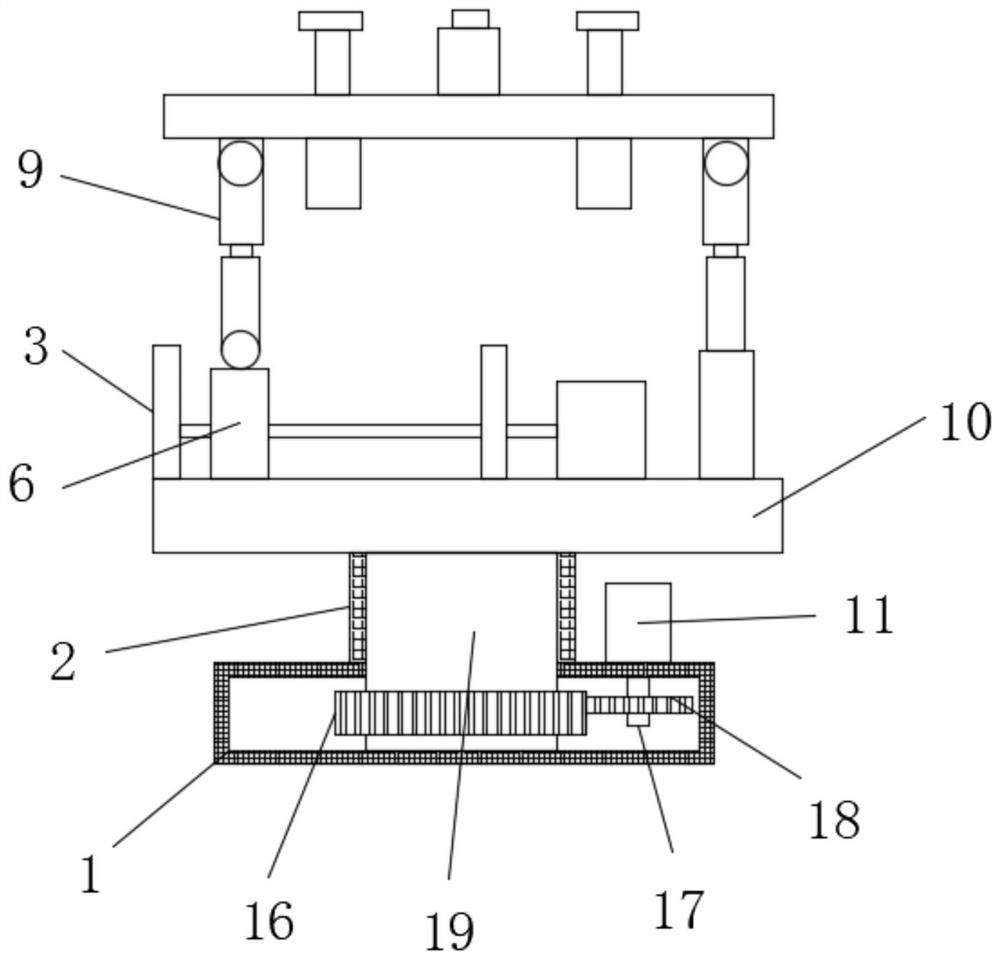

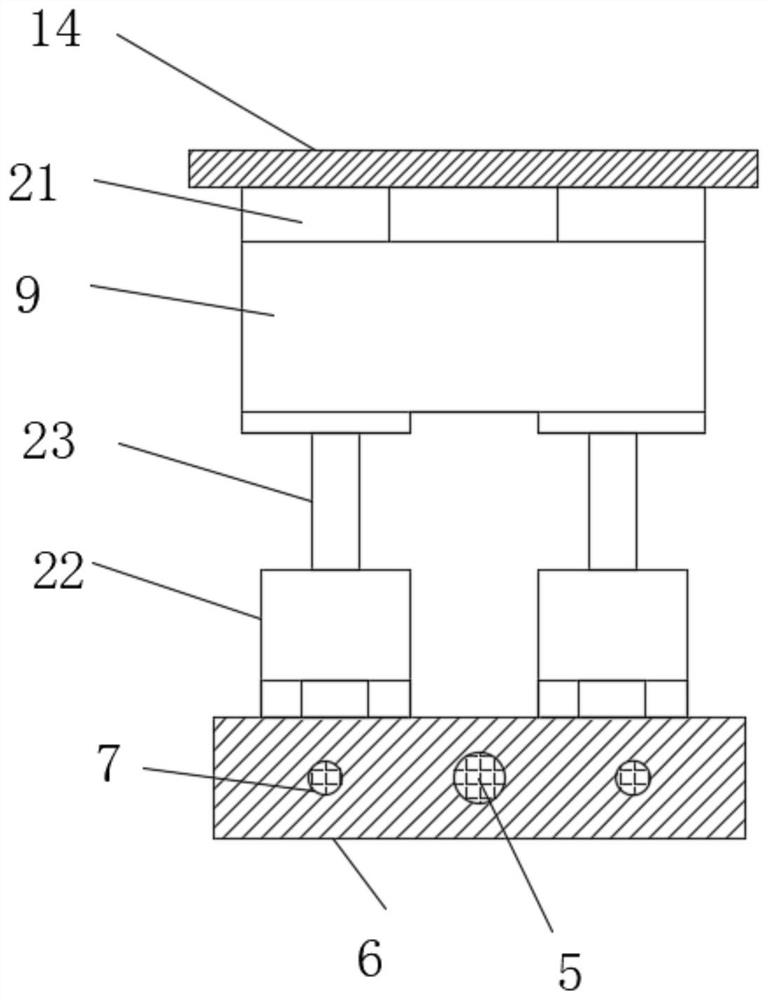

[0024] Such as Figure 1-5 As shown, the embodiment of the present invention provides a high-precision segment clamping and positioning mechanism for a ring-type segment assembly machine, including a base 1, a connecting seat 2 is fixedly connected to the middle of the top of the base 1, and a connecting seat 2 is connected to the top of the connecting seat 2 in rotation. The mounting plate 10, the top side of the base 1 is fixedly connected with the second motor 11, the output end of the second motor 11 is fixedly connected with the shaft 17, the outer side of the shaft 17 is fixedly connected with the pinion 18, and the outer side of the pinion 18 is meshed A toothed ring 16 is connected, the middle part of the toothed ring 16 is fixedly connected with a connecting column 19, the top of the connecting column 19 is fixedly connected in the middle of the bottom of the mounting plate 10, and the top end of the mounting plate 10 is fixedly connected with the first rotating plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com