Helical gear side reducer arrangement structure

A technology for arranging structures and helical gears, which is applied to gear transmissions, belts/chains/gears, transmissions, etc., to achieve the effects of improved load-carrying capacity, long meshing time, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

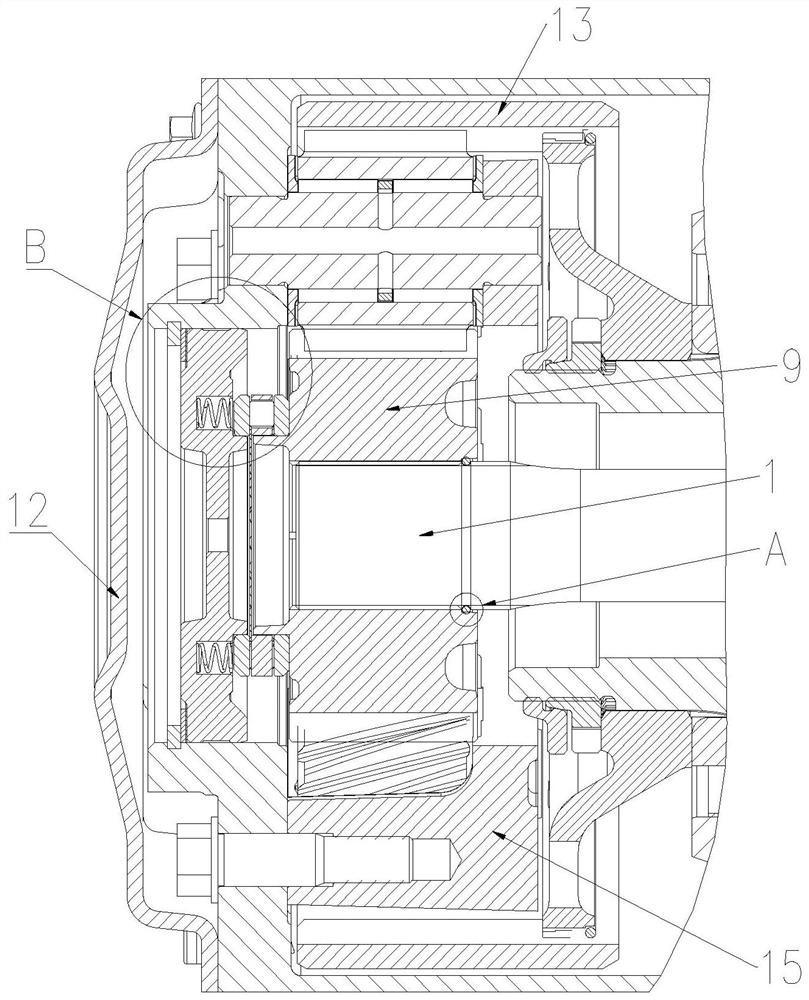

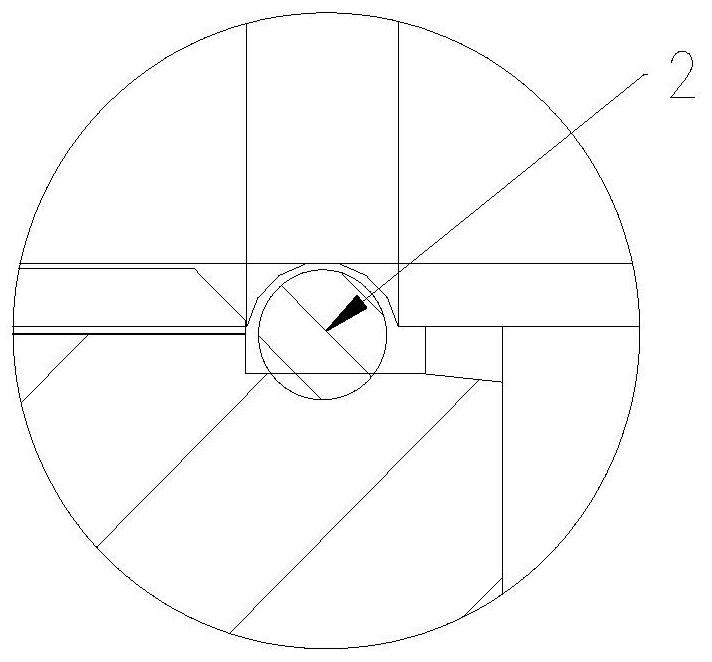

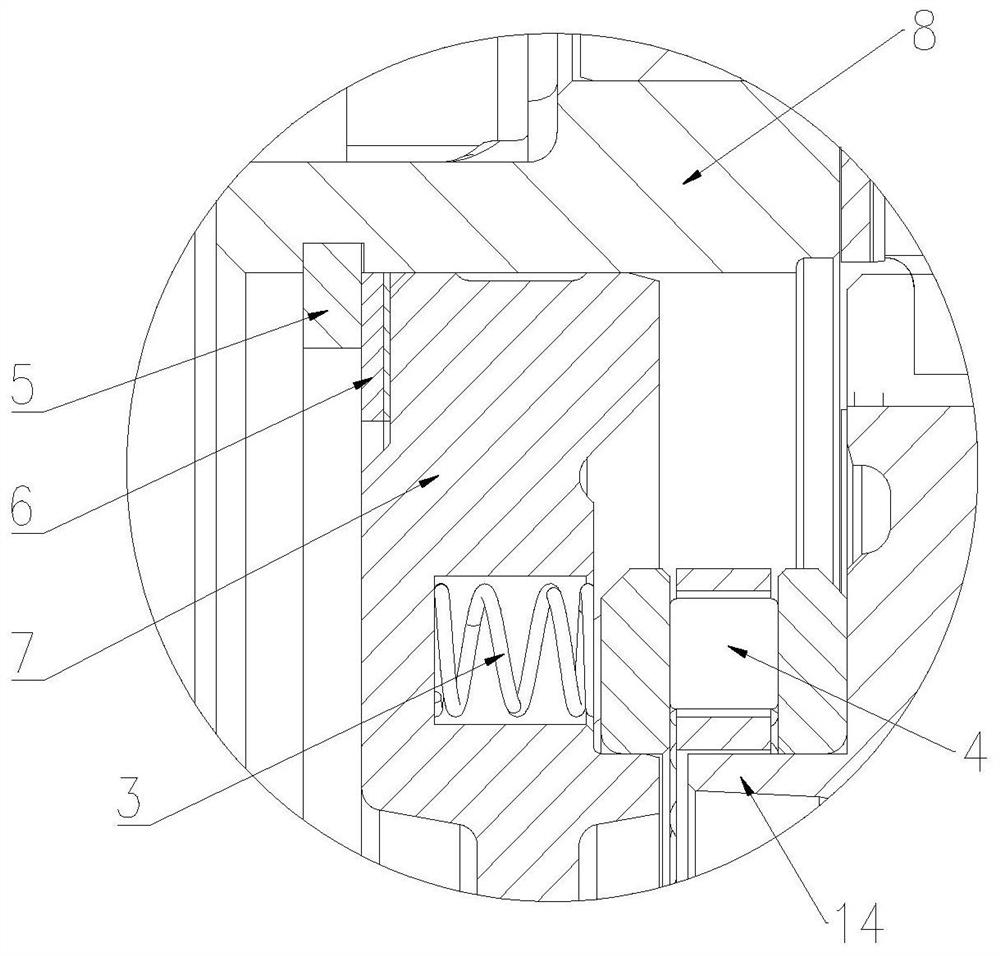

[0030] like figure 1 , 3 As shown in and 4, the arrangement structure of the helical gear side reducer includes a half shaft 1, a cross shaft 11, a ring gear 13, a sun gear 9 and a planetary gear 15, and one end of the half shaft 1 abuts against the cross shaft through a push pin 10 11. The other end of the axle shaft 1 is connected with a sun gear 9, the sun gear 9 is a helical gear, and the side of the sun gear 9 away from the cross shaft 11 is provided with a bearing seat 7, and the bearing seat 7 is close to one side of the sun gear 9. The side is connected with a thrust bearing 4, and the thrust bearing 4 abuts against the sun gear 9, and the planet gear 15 and the ring gear 13 are helical tooth structures, and the planet gear 15 meshes with the sun gear 9 and the ring gear 13 respectively.

[0031] The sun gear 9, the planetary gear 15 and the ring gear 13 are all designed as a helical tooth structure to make the meshing better. The meshing process between the helical t...

Embodiment 2

[0033] like Figure 1-4 As shown, the arrangement structure of the helical gear side reducer includes a half shaft 1, a cross shaft 11, a ring gear 13, a sun gear 9 and a planetary gear 15, and one end of the half shaft 1 abuts against the cross shaft 11 through a push pin 10, The other end of the half shaft 1 is connected with a sun gear 9, the sun gear 9 is a helical gear, the side of the sun gear 9 away from the cross shaft 11 is provided with a bearing seat 7, and the side of the bearing seat 7 close to the sun gear 9 is connected There is a thrust bearing 4, the thrust bearing 4 abuts against the sun gear 9, the planet gear 15 and the ring gear 13 are helical tooth structures, and the planet gear 15 meshes with the sun gear 9 and the ring gear 13.

[0034] The sun gear 9, the planetary gear 15 and the ring gear 13 are all designed as a helical tooth structure to make the meshing better. The meshing process between the helical tooth structures is an excessive process, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com