Multi-frequency selection noise reduction device

A multi-frequency, noise reduction technology, applied in the direction of instruments, synthetic resin layered products, electrical equipment structural parts, etc., to achieve the effect of high practicability, good sound insulation and noise reduction effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

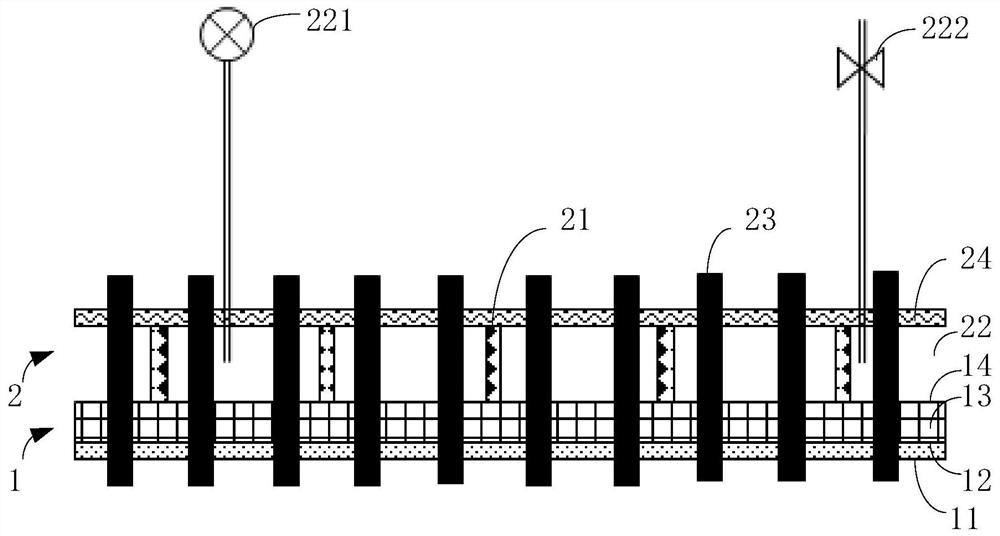

[0038] Such as figure 1 As shown, the multi-frequency selective noise reduction device in Embodiment 1 of the present invention is composed of an inner layer noise reduction unit 1 and a vacuum noise reduction unit 2 . The inner layer noise reduction unit 1 includes an inner substrate 11 , an inner cladding layer 12 , an inner sound absorbing layer 13 and an inner sound insulating layer 14 from inside to outside (the inside is closer to the noise source). The outermost part of the vacuum noise reduction unit 2 is a vacuum outer frame 24 , and the vacuum outer frame 24 is supported on the panel of the inner sound insulation layer 14 through the first vibration-damping connector 21 to form an airtight vacuum layer 22 . The vacuum noise reduction unit 2 further includes a heat conduction connecting member 23 , and the heat conduction connecting member 23 penetrates the inner layer noise reduction unit 1 and the airtight vacuum layer 22 . A vacuum gauge 221 and a vacuum valve 222...

Embodiment 2

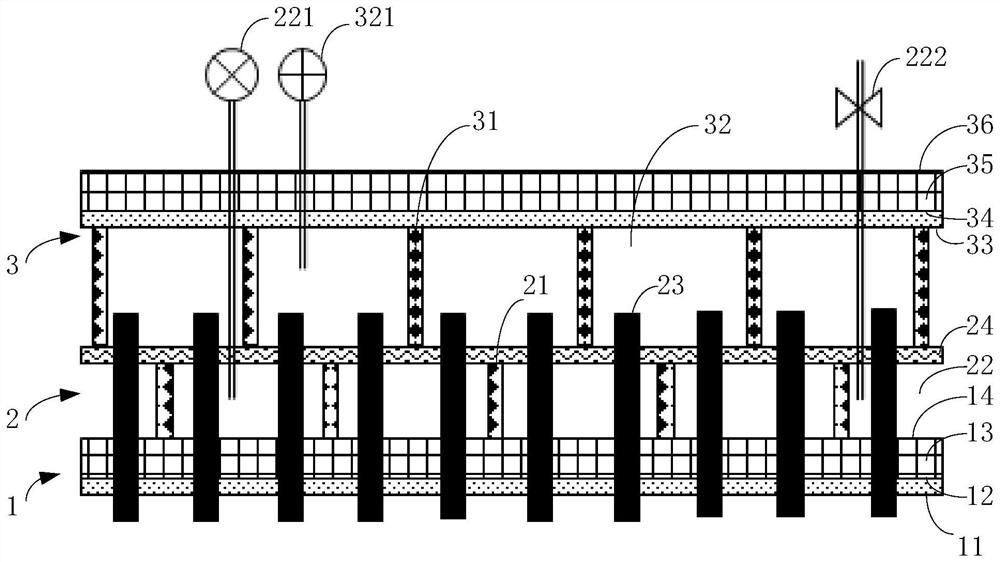

[0043] Such as figure 2 As shown, the multi-frequency selective noise reduction device according to Embodiment 2 of the present invention is composed of an inner layer noise reduction unit 1 , a vacuum noise reduction unit 2 and an outer layer noise reduction unit 3 . The inner layer noise reduction unit 1 includes an inner substrate 11 , an inner cladding layer 12 , an inner sound absorbing layer 13 and an inner sound insulating layer 14 from inside to outside (the inside is closer to the noise source). The outermost part of the vacuum noise reduction unit 2 is a vacuum outer frame 24 , and the vacuum outer frame 24 is supported on the panel of the inner sound insulation layer 14 through the first vibration-damping connector 21 to form an airtight vacuum layer 22 . The vacuum noise reduction unit 2 further includes a heat conduction connecting member 23 , and the heat conduction connecting member 23 penetrates the inner layer noise reduction unit 1 and the airtight vacuum la...

Embodiment 3

[0048] Embodiment 3 is a specific application embodiment of the noise reduction device of the present invention. When the noise spectrum of the high-noise equipment pipeline presents a wide-band, high-intensity feature, and the temperature of the equipment pipeline is 30-40°C, and the temperature difference between the inside and outside air is less than or equal to 5°C, the noise reduction device of the present invention only uses the inner layer noise reduction unit 1 and Vacuum noise reduction unit 2, that is, the structure of embodiment 1: specifically, the inner layer substrate 11 is pasted with the inner cladding layer 12, the inner cladding layer 12 is filled with an inner sound-absorbing layer 13, and the inner sound-absorbing layer 13 is attached with an inner sound-insulating layer 14, The inner sound insulation layer 14 is connected to the vacuum outer frame layer 24 through the first vibration-damping connector 21, the vacuum layer 22 is evacuated by a vacuum pump, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com