Pulling plate structure of converter transformer

A technology of converter transformers and pull plates, which is applied in the field of transformers, can solve the problems of magnetic flux leakage in the pull plate structure and low structural strength, and achieve the effects of suppressing magnetic flux leakage, meeting lifting requirements, and facilitating hoisting and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

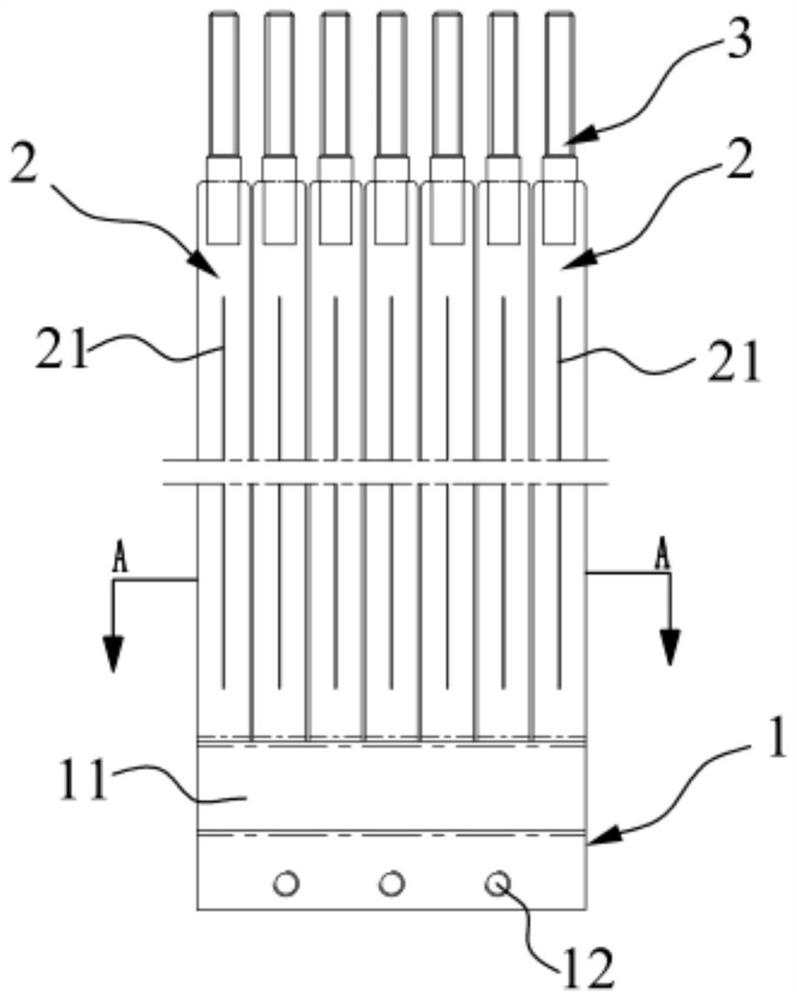

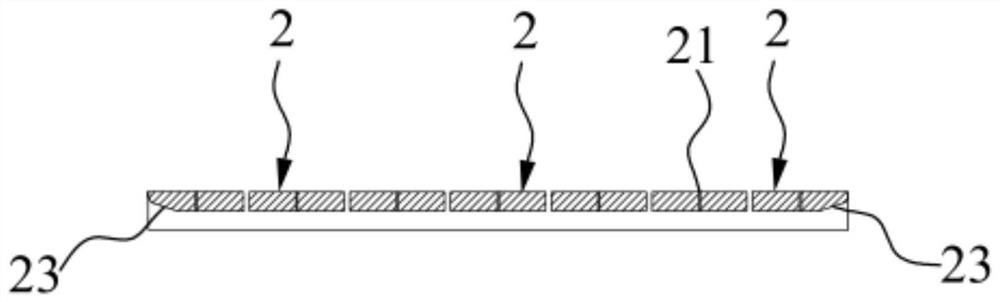

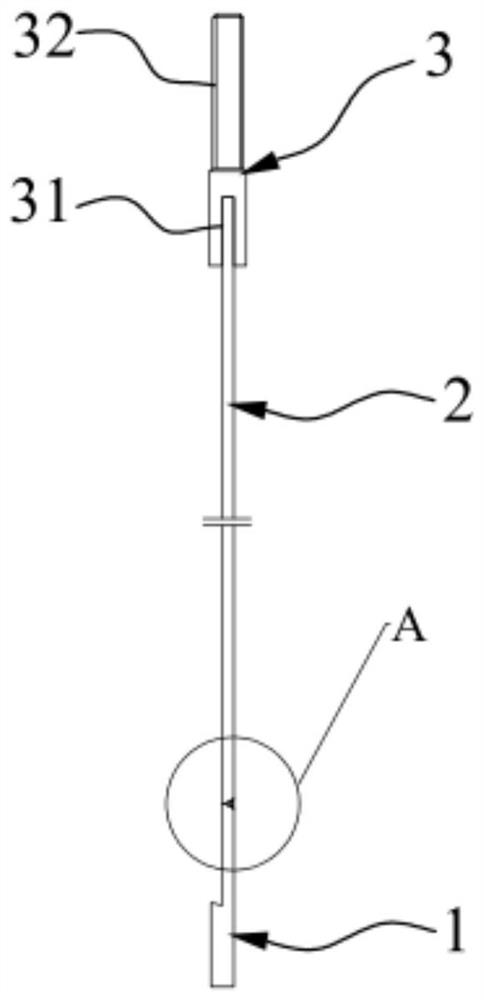

[0040] Such as Figure 1-Figure 12 As shown, the present invention provides a pull plate structure for a converter transformer, including a clamp plate 1 , a pull plate 2 and a lifting piece 3 . There are multiple pull plates 2, which are arranged at intervals along the length direction of the clamp plate 1 and are fixedly connected with the clamp plate 1. The pull plate 2 is provided with a magnetic flux leakage groove 21 along the length direction; the lifting part 3 is provided with multiple, A plurality of lifting parts 3 are fixedly connected with a plurality of pull plates 2 in one-to-one correspondence.

[0041] In this example, refer to the attached figure 1 , The pull plate structure of the converter transformer is composed of a clamp plate 1, seven pull plates 2 and seven lifting parts 3, each pull plate 2 is about 50mm wide, and the gap between two adjacent pull plates 2 is 2.5mm-3.5mm , preferably 3mm in the present embodiment, can effectively reduce the eddy cur...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the pull plate 2 in this embodiment is a high-strength low-magnetism steel plate. Specifically, 14MnMoNbB high-strength low-magnetic steel plate is used. The low-magnetic steel has no induction to ferromagnetism, has stable structure, excellent mechanical properties, low magnetic permeability and high resistivity. The drawing plate 2 is made of high-strength and low-magnetic steel plate, which can further reduce eddy current loss and further suppress the occurrence of magnetic flux leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com