Efficient surface mounting type permanent magnet synchronous motor structure with cooling structure

A technology of permanent magnet synchronous motor and cooling structure, applied to synchronous motor with static armature and rotating magnet, magnetic circuit shape/pattern/structure, magnetic circuit and other directions, can solve the problem of small air gap magnetic density and irreversible permanent magnet Problems such as demagnetization and large harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

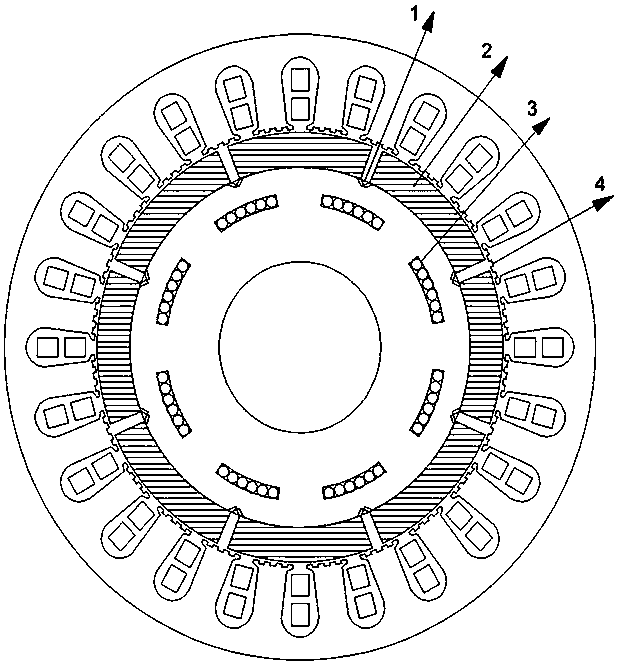

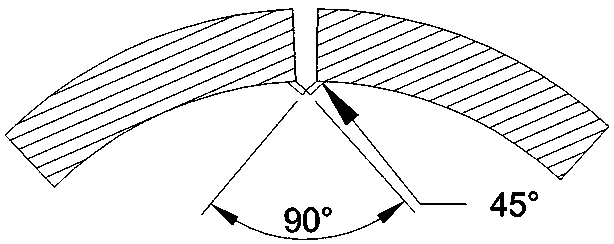

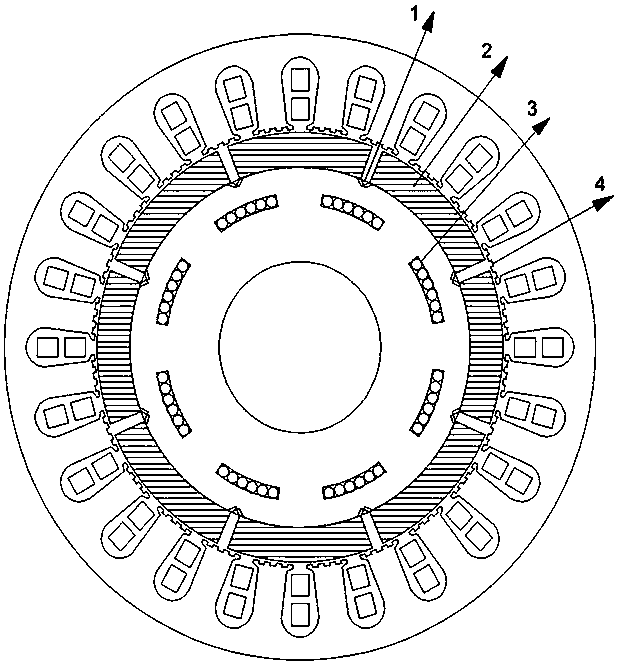

[0010] Such as figure 1 It is a structural schematic diagram of a high-efficiency surface-mounted permanent magnet synchronous motor with a cooling structure of the present invention; figure 2 It is a partial enlarged view of the magnetic bridge of a high-efficiency surface-mounted permanent magnet synchronous motor structure with a cooling structure in the present invention; it is characterized in that the motor adopts an inner rotor permanent magnet synchronous motor, and the internal structure of the stator and the rotor is improved; The above-mentioned stator teeth are added with 3 equidistant virtual slots on the original basis, and these virtual slots do not need windings; the surface of the rotor is a magnetic pole, and a 90° permanent magnet bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com