Permanent magnet motor rotor with radial and axial magnetism gathering characteristics

A permanent magnet motor, axial technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electromechanical devices, etc., can solve the problems of increasing copper loss, reducing efficiency, complex motor structure, etc., to increase efficiency, improve production efficiency, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

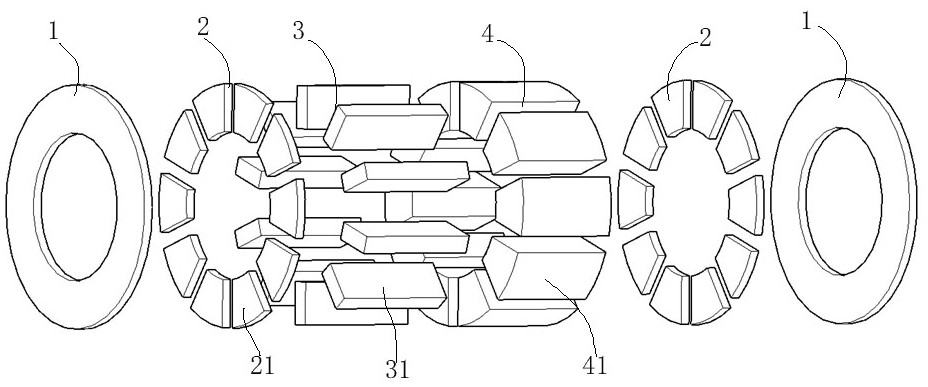

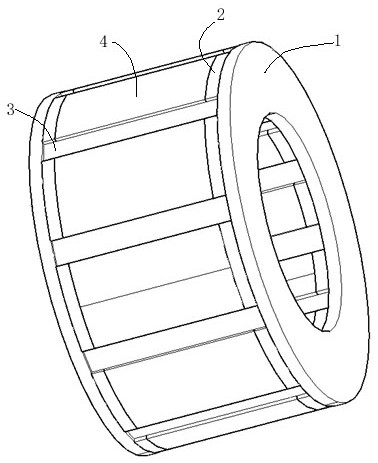

[0031] Such as Figure 1 to Figure 3 As shown, a permanent magnet motor rotor with radial and axial magnetization characteristics includes: a motor shaft, a radial permanent magnet array 3 , a radial yoke array 4 , an axial permanent magnet array 2 and an axial back yoke 5 .

[0032] The motor shaft serves as the basis for structural support and power output.

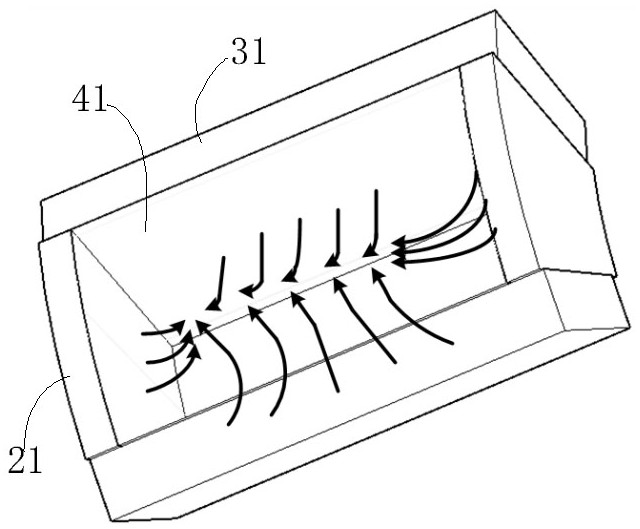

[0033] The radial permanent magnet array 3 contains a plurality of first permanent magnets 31, and the first permanent magnets 31 are distributed in a circular array around the outer cylindrical surface of the motor shaft. The first permanent magnets 31 are in the shape of a cuboid, and each The first permanent magnets 31 are all magnetized tangentially, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com