Processing technology of special-shaped coil

A processing technology and special-shaped coil technology, applied in coil manufacturing, instruments, measuring devices, etc., can solve problems such as loose air-core coils, failure to meet user's requirements for the shape of air-core coils, and failure to achieve bending effects, so as to prevent looseness and improve Pressing stability and molding effect, the effect of avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

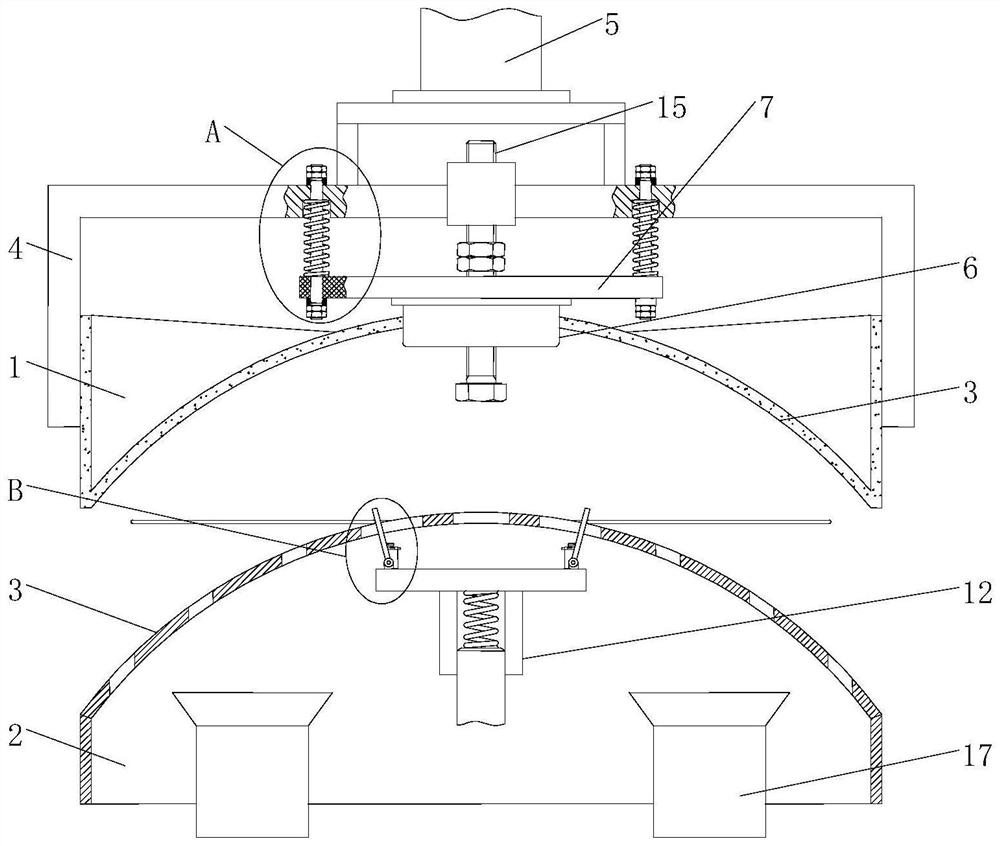

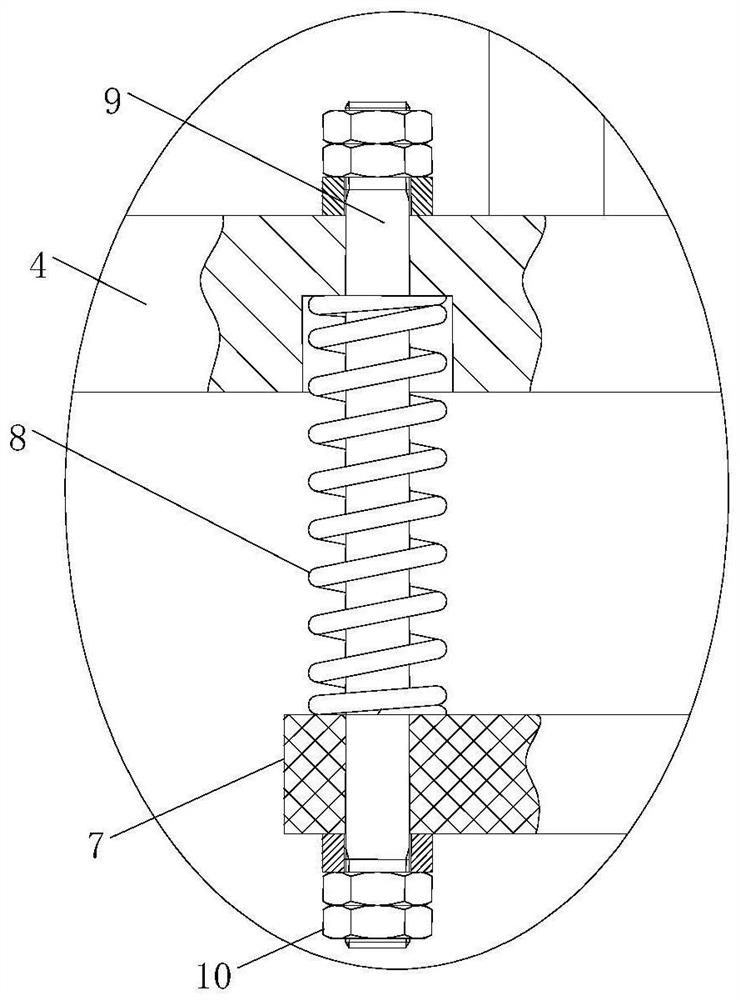

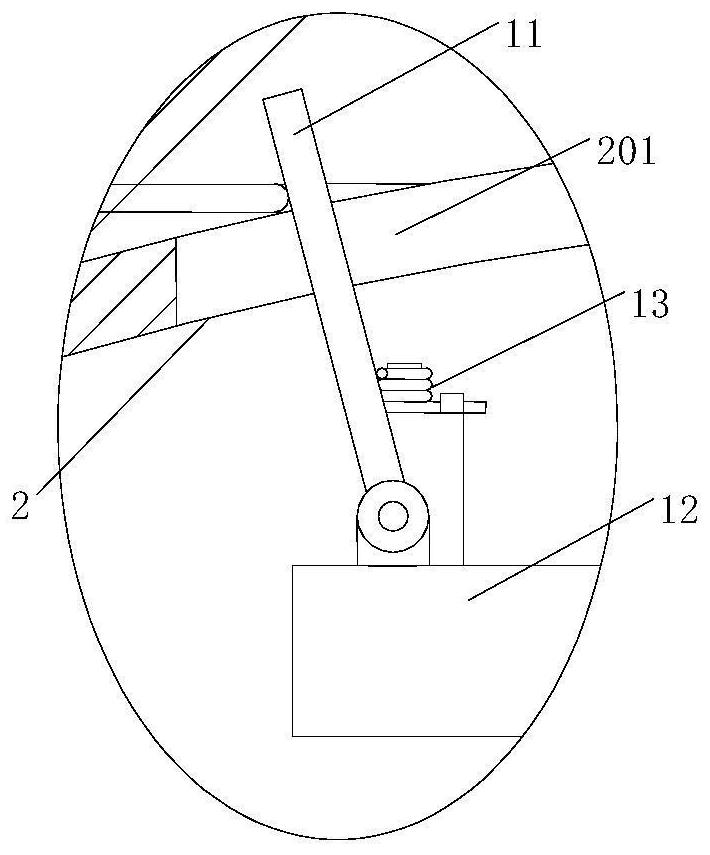

[0036] Example 1. A processing technology for special-shaped coils, comprising the following steps:

[0037] ① Use self-adhesive paint to paint the surface of the enameled wire to form a self-adhesive enameled wire. The self-adhesive paint layer is the existing self-adhesive paint with secondary bonding function. The self-adhesive paint can be heated after the hollow coil is wound. or energized for secondary bonding; then wind the self-adhesive enameled wire to form a hollow coil with a flat shape to obtain a hollow coil A;

[0038] ②Place the air-core coil A on the lower mold base to get the air-core coil B;

[0039] ③Heating or energizing the hollow coil, so that the self-adhesive paint on the surface of the B hollow coil is converted from a solid state to a molten state, and the C hollow coil is obtained;

[0040] ④The C hollow coil is pressed by the upper template, so that the C hollow coil changes from a flat shape to an arc shape curved along the thickness direction un...

Embodiment 2

[0054] Example 2. A processing technology for special-shaped coils, comprising the following steps:

[0055] ① Use self-adhesive paint to paint the surface of the enameled wire to form a self-adhesive enameled wire. The self-adhesive paint layer is the existing self-adhesive paint with secondary bonding function. The self-adhesive paint can be heated after the hollow coil is wound. or energized for secondary bonding; then wind the self-adhesive enameled wire to form a hollow coil with a flat shape to obtain a hollow coil A;

[0056] ②Place the air-core coil A on the lower mold base to get the air-core coil B;

[0057] ③Heating or energizing the hollow coil, so that the self-adhesive paint on the surface of the B hollow coil is converted from a solid state to a molten state, and the C hollow coil is obtained;

[0058] ④The C hollow coil is pressed by the upper template, so that the C hollow coil changes from a flat shape to an arc shape curved along the thickness direction un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com