Machining method for thin-wall gear ring with small width-diameter ratio

A thin-walled ring gear and processing method technology, which is applied in the direction of expanding mandrels, etc., can solve the problem of inability to meet the precision requirements of the flower keyboard ring gear, and achieve the effects of improving processing rigidity, meeting high precision requirements, and improving aspect ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] A processing method of a thin-walled ring gear with a small aspect ratio of the present invention comprises the following steps:

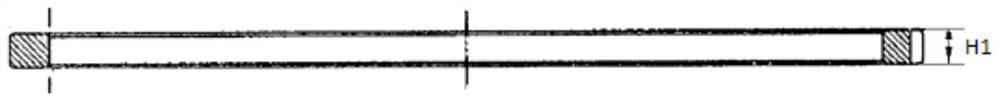

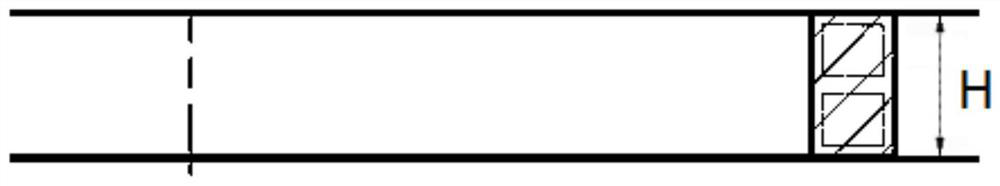

[0043] 1) Determine the axial width H of the blank according to the required thin-walled ring gear with a small width-to-diameter ratio, and H satisfies the conditional formula:

[0044] H=mH1+(m-1)a+2b;

[0045] Among them, m is an integer greater than or equal to 2 and less than or equal to 4; H1 is the axial width of the thin-walled ring gear with a small aspect ratio required, a is the loss per cutting, and b is the end face turning loss of the blank;

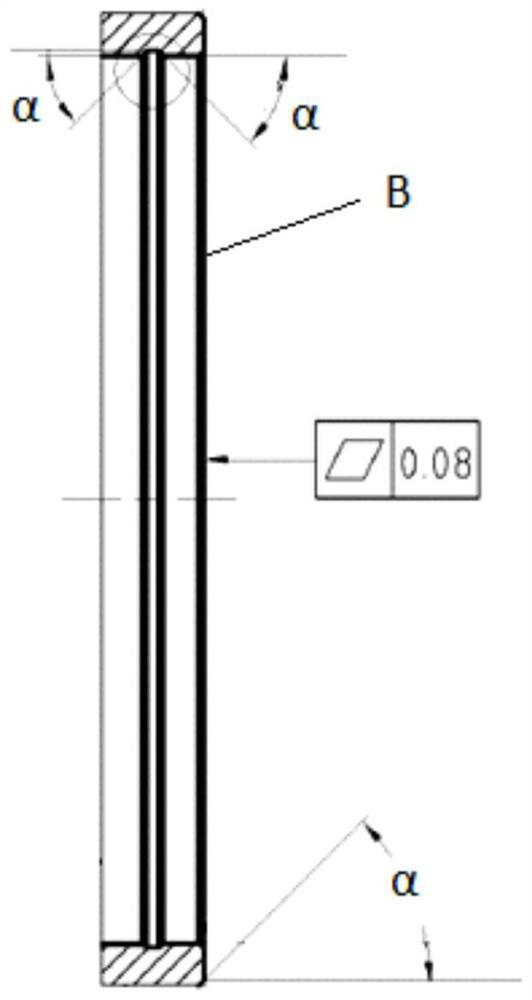

[0046] 2) Use the jaws to clamp the blank, set the end face of the blank close to the jaws as the A end face, and the other end face as the B end face; then turn the inner hole of the blank to the required diameter of the design, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com