Paper surface plasterboard cutting process

A paper-faced gypsum board and cutting technology, which is applied in metal processing, glass production, etc., can solve the problems that gypsum board is difficult to cut, is not suitable for cutting large-scale gypsum board, and is limited in size, so as to achieve easy cutting, easy splitting, and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

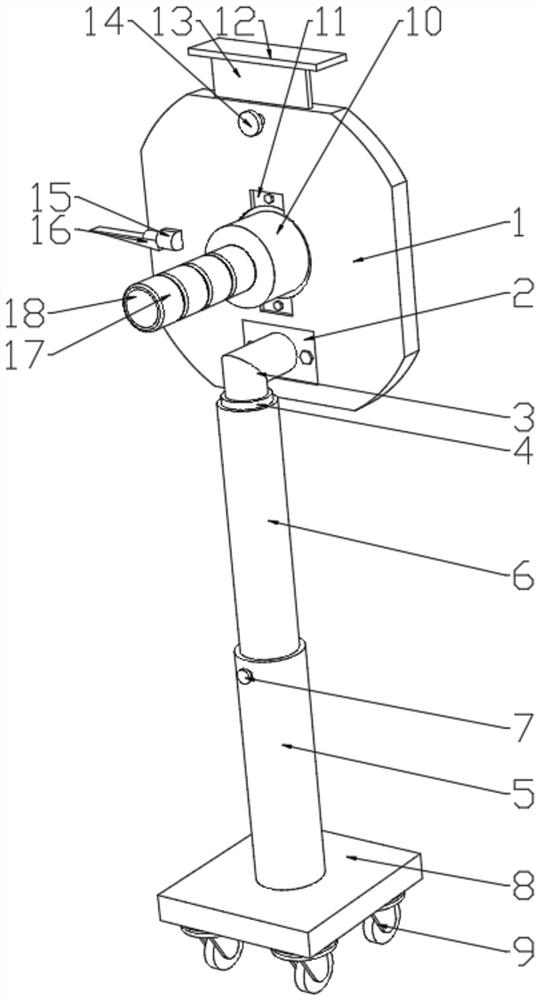

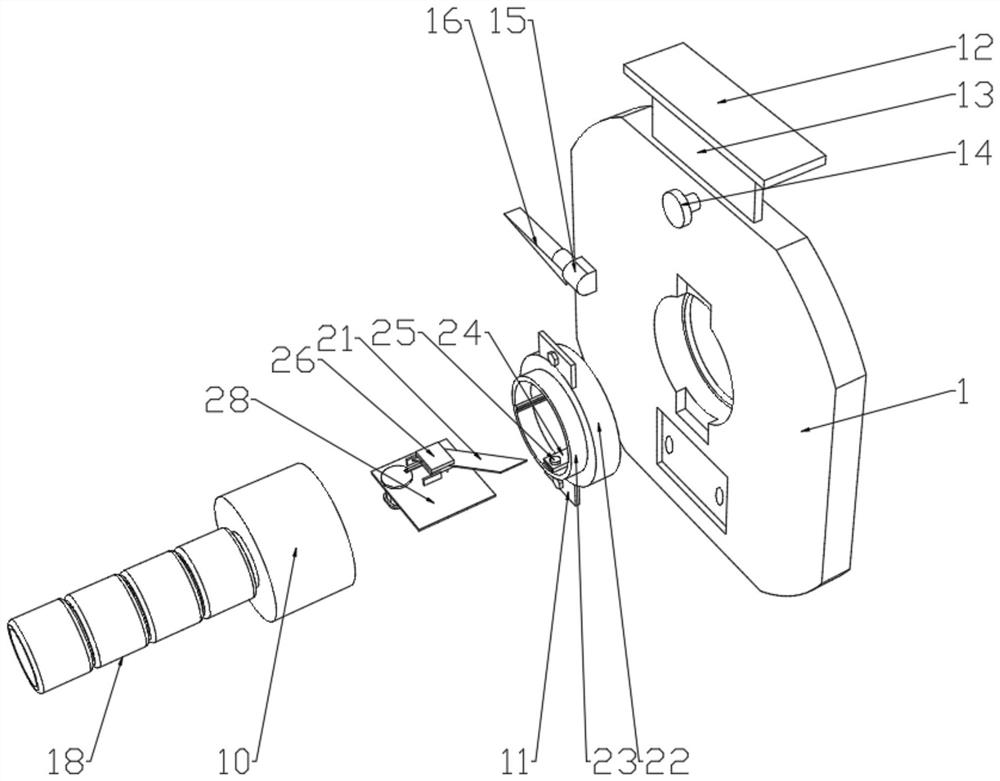

[0039] See Figures 1 to 5 , in the present embodiment provides a paper gypsum board cutting process, comprising a cutting plate 1 and a moving plate 8, the cutting plate 1 is provided with a connection plate 2, the connection plate 2 is fixed connected to the connecting tube 3, the connecting tube 3 is fixed to connect the limited bit ring 4, the moving plate 8 is provided with several moving wheels 9 at the bottom, the moving plate 8 is fixed to be connected to the fixed rod 5, the fixed rod 5 sliding connection is connected to the telescopic rod 6, the fixing rod 5 is provided with a first fastener 7, the connecting tube 3 is connected to the telescopic rod 6 card connection;

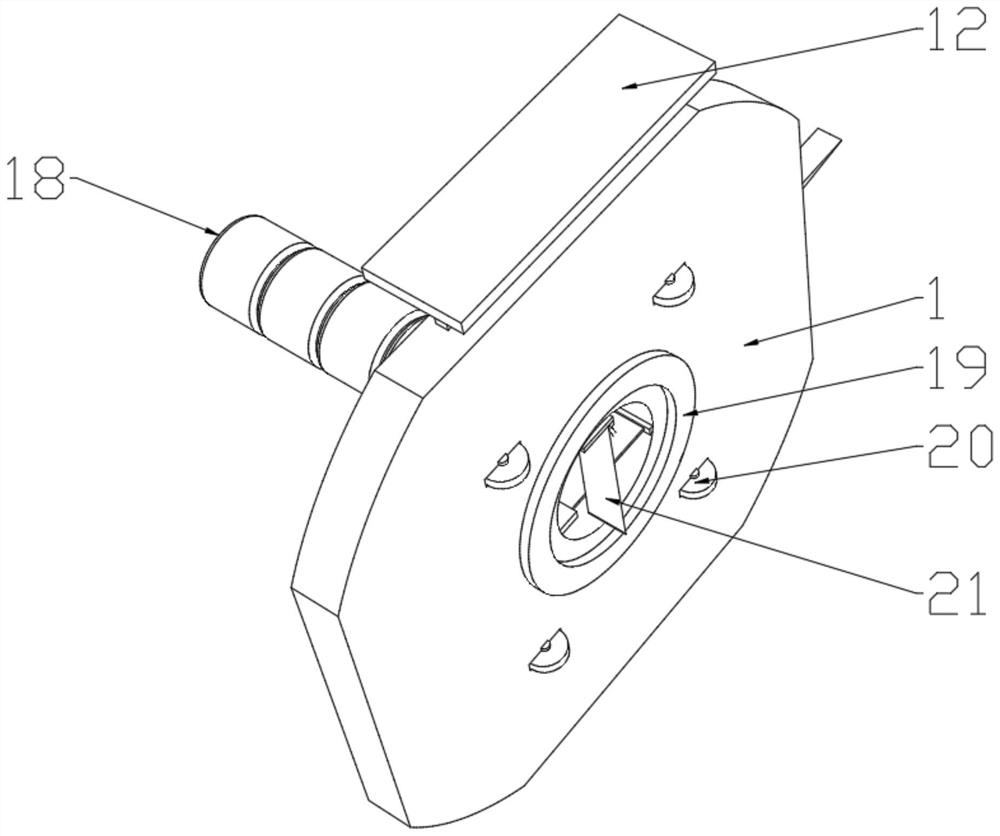

[0040] The cutting plate 1 fixed connection is connected to a fixing ring 19, the cutting plate 1 is provided with a mounting ring 22, the mounting ring 22 is fixed to a threaded joint 23, the threaded joint 23 is connected with a cover 10, the outer cover 10 is fixed to be connected to a handle 18, the h...

Embodiment 2

[0049] See Figure 6 , in the present embodiment, the cutting plate 1 fixed connection fin 36, the cutting plate 1 corresponding to the cover 10 on both sides of the connecting frame 32, the connecting frame 32 and the limiting column 36 sliding connection, the cutting plate 1 is provided with a fourth fastener 31, the connecting frame 32 slide connection is connected to the activity plate 33, the activity plate 33 is provided with a fifth fastener 34.

[0050] The two cutting plates 1 are connected by the connecting frame 32 and the activity plate 33, adjust the height of the activity plate 33, so that the two cutting plates 1 are located on both sides of the gypsum board, while the sides of the gypsum board are scratched, so that the gypsum board is easier to break open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com