Novel structure for artificial sunflower straw board and assembly method

A new type of structure, sunflower straw technology, applied in chemical instruments and methods, mechanical processing of plant materials, lamination devices, etc., can solve the problem of not reducing the transverse strength, achieve the standard of transverse strength, reduce production costs, and enhance the longitudinal strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

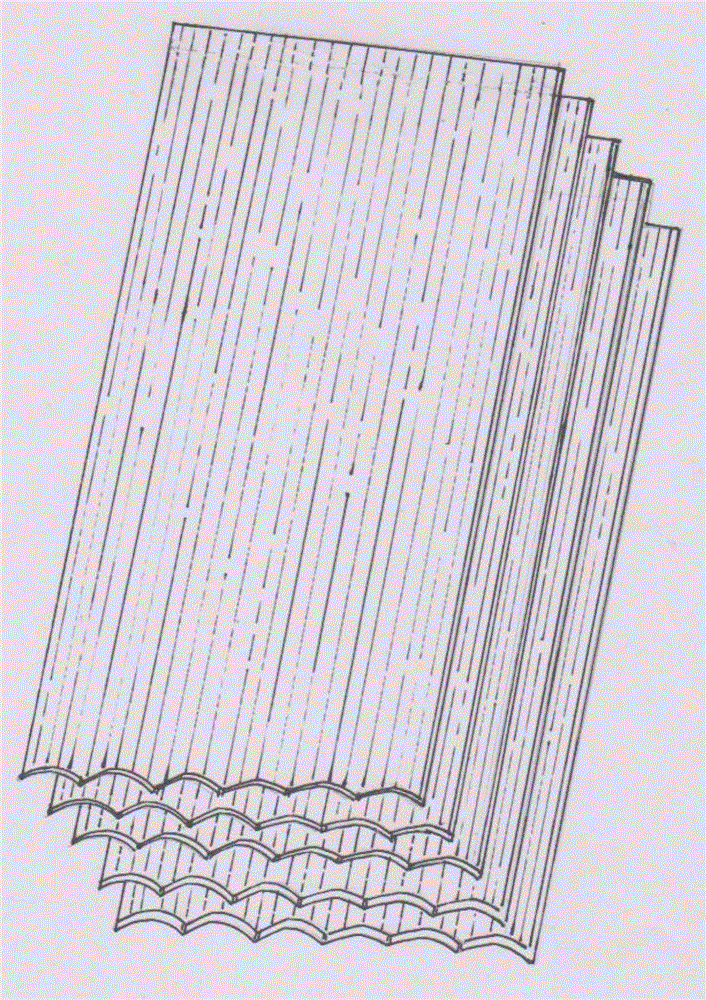

Embodiment 1

[0017] First, the whole sunflower stalks are fed into the self-developed peeling core machine, which processes the sunflower stalks into long strips without skins and cores, and then sizing, which can be done by gluing or spraying. The rubber material can be urea-formaldehyde glue or phenolic glue, or isocyanate glue, and then the stalks after sizing are sent to the self-developed pavement assembly machine along the length, and the pavement assembly machine The long stalks are paved in a single direction, that is, all are longitudinal slab structures, that is, paved into 1.3 meters wide and 2.6 meters long, and the thickness is the thickness specification of each pressed plate according to the thickness compression ratio of 1:2.3 to 1:3.3 To set the thickness of the slab, and then the slab is sent to the hot press by the conveyor belt of the pavement assembly machine, heated and pressurized, solidified and formed, cut four sides, and the product is put into storage, that is, th...

Embodiment 2

[0019] The sunflower stalks after sizing are sent into the pavement and assembly machine, and the work of embodiment 1 is completed by the pavement and assembly machine, except that a layer of wood is respectively laid on both sides of the back surface of the slab before being sent into the hot press machine. The veneer is used as the two sides of the plate, the thickness of the veneer is 2 mm, the width is 1.3 meters, and the length is 2.6 meters. The other process conditions are the same as in Embodiment 1, and a qualified new structural plate can also be produced.

Embodiment 3

[0021] Put a piece of kraft paper or gypsum board paper of the same size on the two sides of the back surface of the complete slab sent out of the paving and billet assembly machine before entering the hot press machine as the two sides of the back surface of the board, and other process conditions are as Example 1 can also produce qualified new structural boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com