Preparation method of conical mica tube

A mica tube and tapered technology, which is applied in the field of preparation of tapered mica tubes, can solve the problems of difficult processing and achieve the effects of reducing the difficulty of processing and manufacturing, improving product quality, and preventing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The application will be described in further detail below in conjunction with the accompanying drawings.

[0041] The embodiment of the present application discloses a method for preparing a tapered mica tube, which specifically includes the following steps:

[0042] Step 1. Preparation of raw materials. Mix mica powder and binder in a certain proportion according to requirements and then stir to obtain raw materials. Organic silica gel adhesive can be used as the binder.

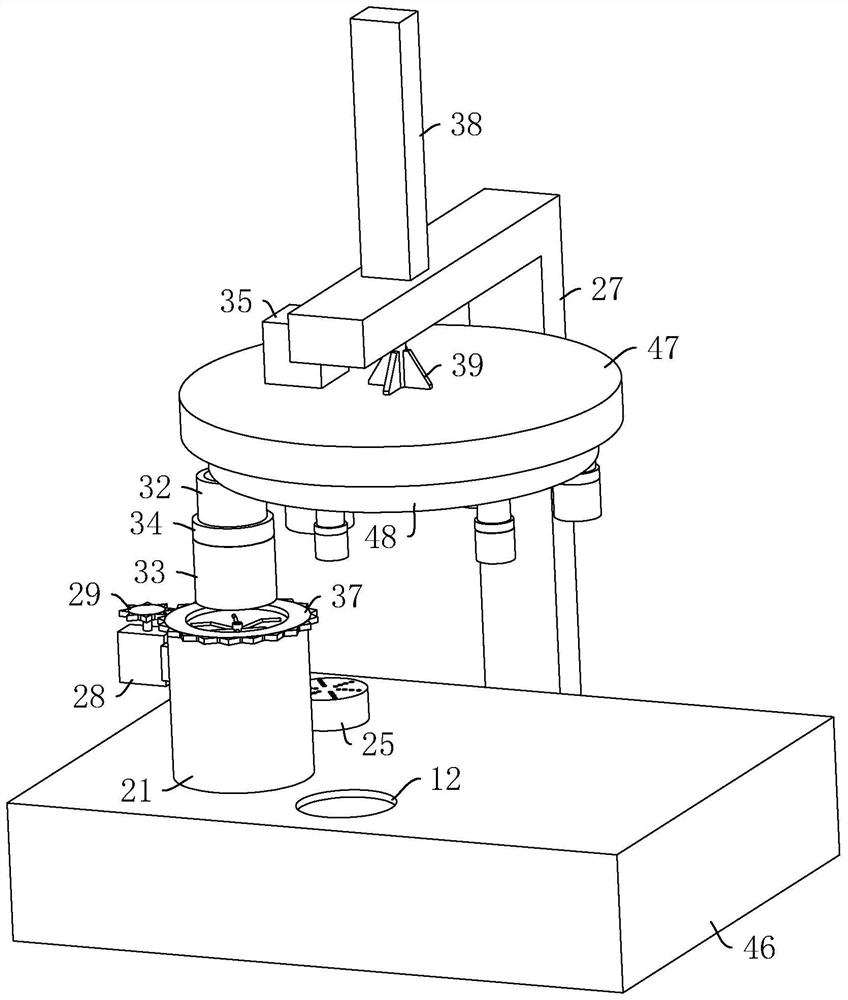

[0043] Step 2. Preliminary shaping. Workers hold pipes to pump raw materials into corresponding preparation molds, and use extrusion equipment to extrude and shape the raw materials in the preparation molds.

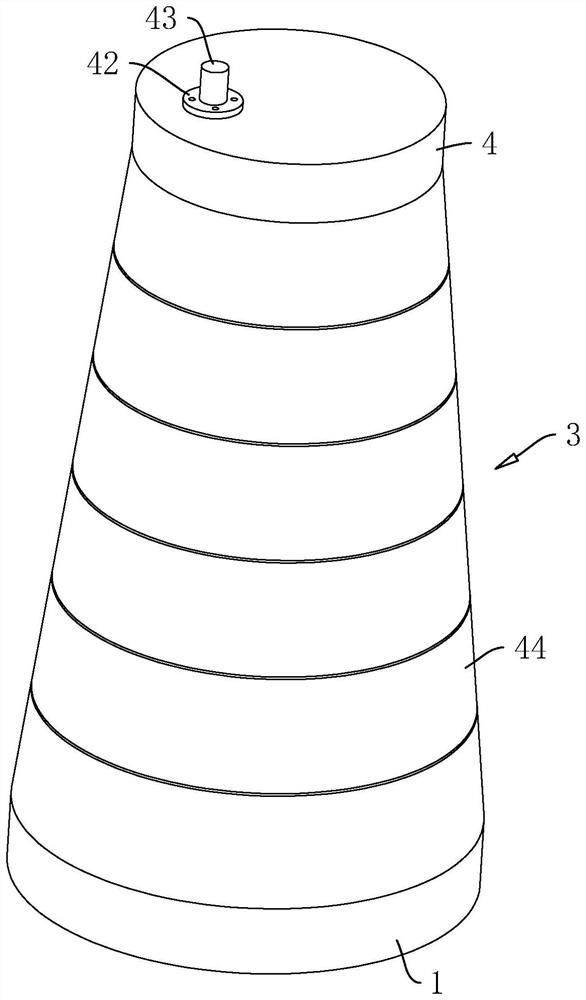

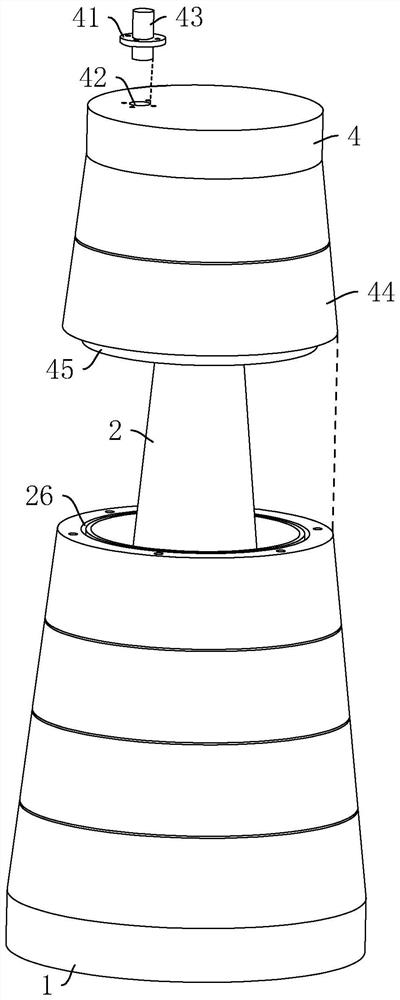

[0044] refer to figure 1 and figure 2 , the preparation mold includes a horizontal bottom plate 1, the bottom plate 1 is circular, and the upper surface of the bottom plate 1 is coaxially fixedly connected with a vertical core rod 2. Greater than the cross-sectional area of its upper end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com