Multidimensional intersecting line tapping and cutting system for pipeline

A cutting system and intersecting line technology, used in welding/cutting auxiliary equipment, auxiliary devices, gas flame welding equipment, etc., can solve the problem of low efficiency, and achieve the effect of simple structure, small cumulative error of action, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

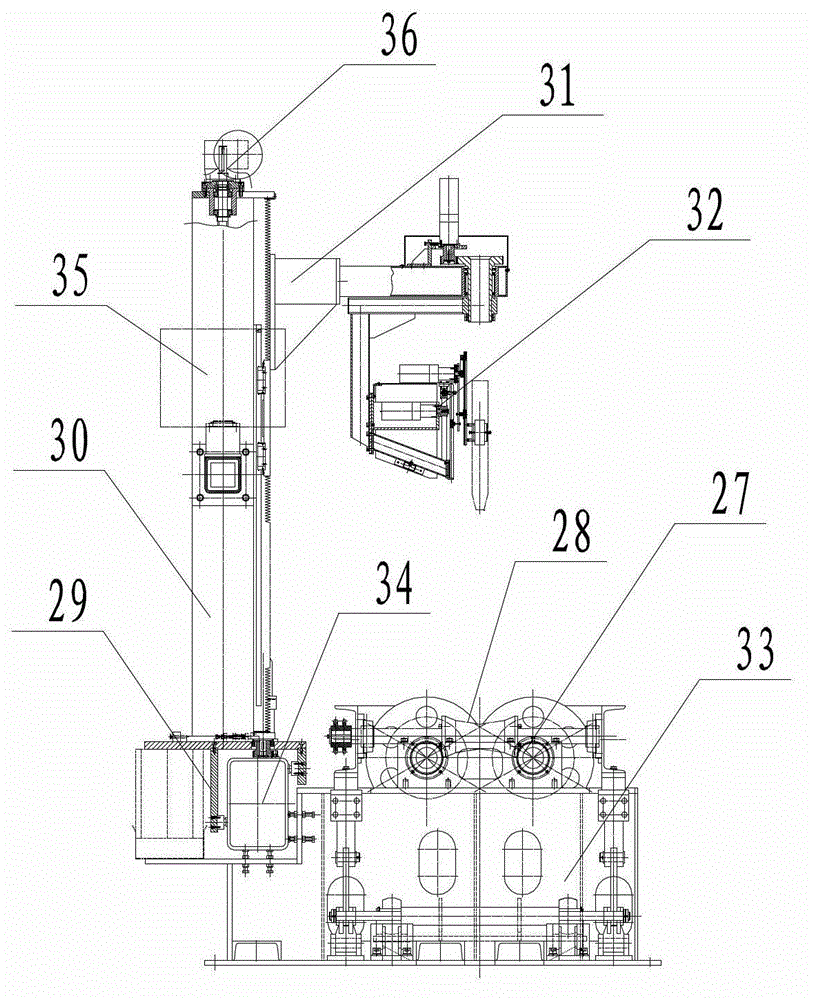

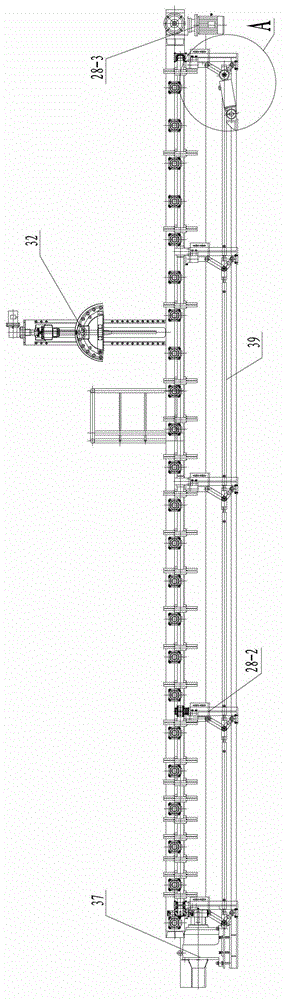

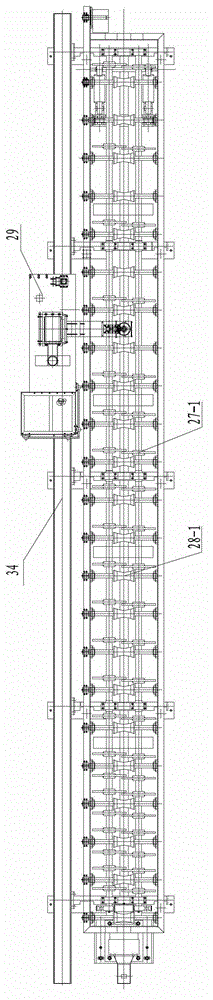

[0022] This embodiment provides a multi-dimensional intersecting line opening cutting system for pipelines, such as figure 1 and image 3 As shown, it is mainly composed of a rotary roller assembly 27, a conveying roller assembly 28, a cutting trolley 29, a column assembly 30, a cross arm 31 and a cutting head 32. The rotary roller assembly 27 and the conveying roller assembly 28 are installed alternately On a roller frame 33, the cutting trolley 29 is arranged on the travel track 34; the roller frame 33 and the travel track 34 are arranged in parallel, and a column assembly 30 is vertically installed on the cutting trolley, and a lifting slide plate 35 is installed on the column assembly 30 to lift the The slide plate 35 is driven by a lift reducer 36 installed on the top of the column assembly, one end of the cross arm 31 is fixedly mounted on the lift slide plate 35, and the other end of the cross arm is fixedly mounted with the cutting head 32; The rotary roller 27-1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com