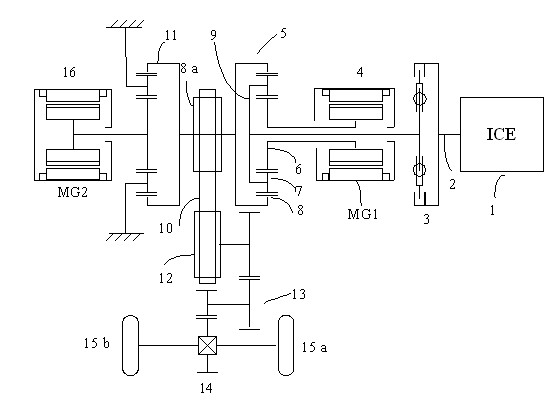

Hybrid power transmission device of dual-mode two-stage planet wheel

A hybrid power and transmission technology, applied in the direction of gear transmission, power plant, transmission, etc., can solve the problems of increasing cost, increasing system complexity, increasing difficulty, etc., and meeting the requirements of reducing speed and torque. It is beneficial to the structural arrangement of the whole vehicle and the effect of reducing the difficulty of processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

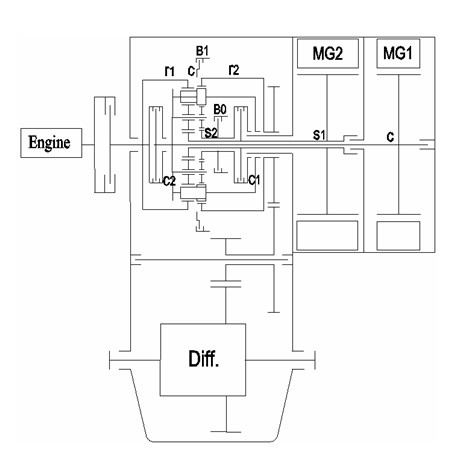

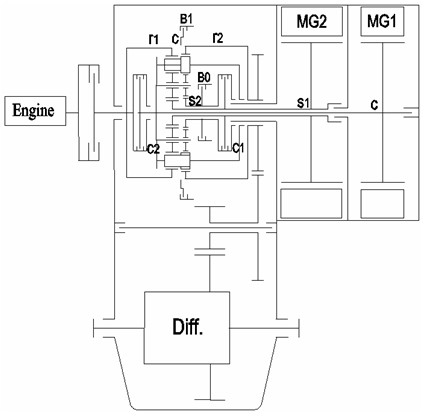

[0043] The mode of operation of the transmission device of the present invention:

[0044] Describe the working method of the scheme through the different working modes of hybrid electric vehicles:

[0045] (1) Engine start: When the engine is started, the motor MG1 can be used to start the engine according to different working conditions. At this time, the clutch C2 is used to couple the first planetary outer ring gear r1 and the planetary carrier C, so that the first planetary sun gear s1 , The first planetary outer ring gear r1 and the planetary carrier C rotate at the same speed, the motor MG1 rotates and outputs torque, and the power is transmitted to the engine through the planetary carrier C and the first planetary outer ring gear r1 to drive the engine to start; the motor MG2 can also be used to start the engine At this time, the planetary carrier C is locked by the brake B1, the motor MG2 rotates and outputs torque, and the power is transmitted to the engine through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com