Safety protection device for hoisting graphite blank

A safety protection device, graphite technology, applied in manufacturing tools, presses, etc., can solve problems such as loose fixtures, graphite billets falling and dumping, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

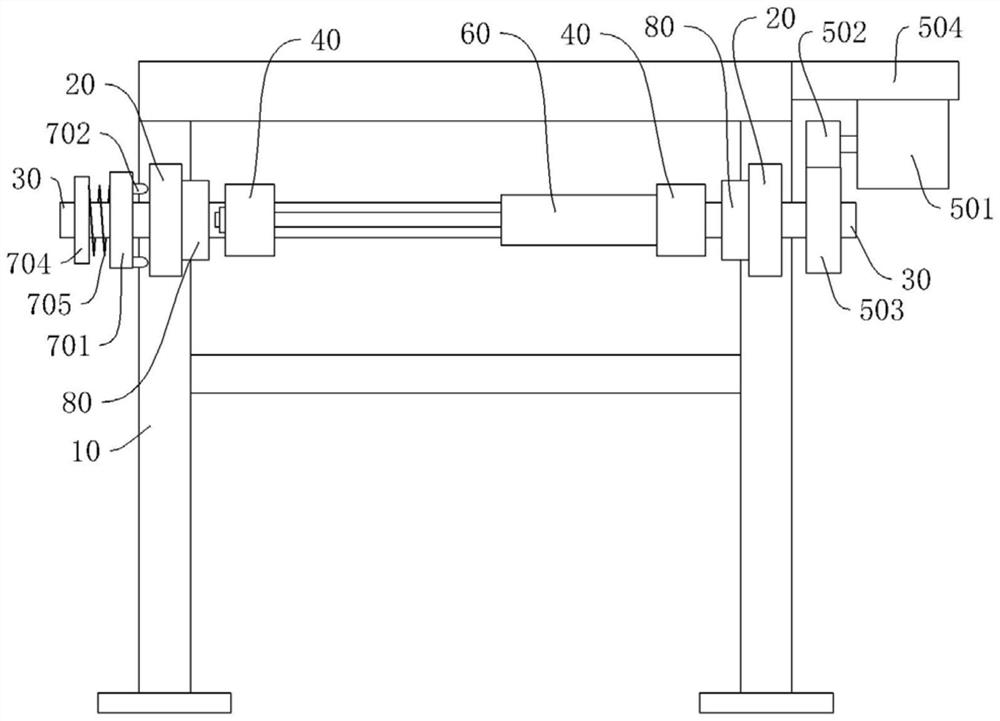

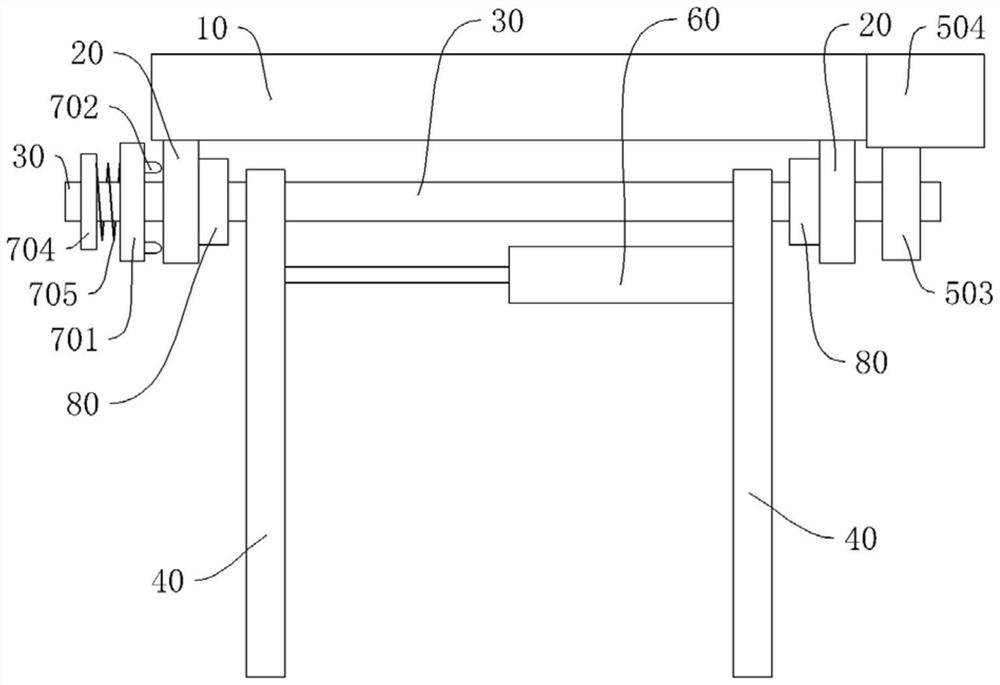

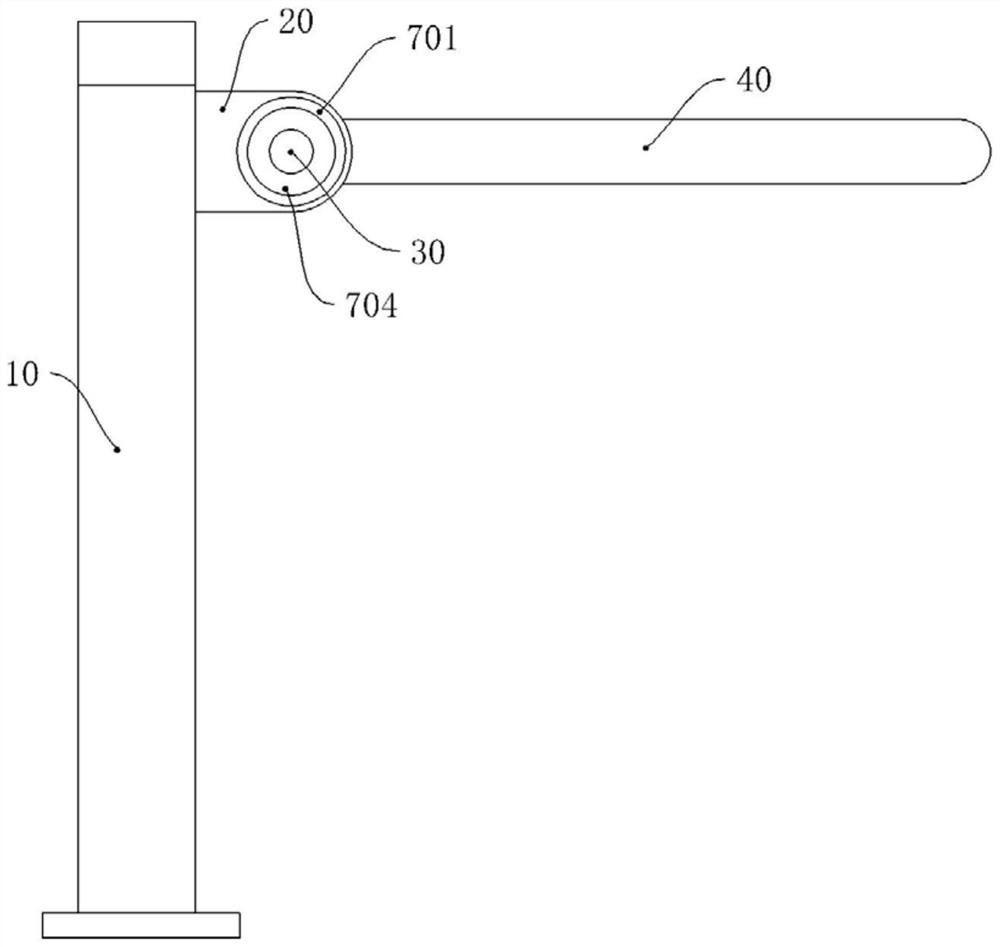

[0028] The reference numerals in the accompanying drawings of the description include: support column 10, fixed plate 20, connecting shaft 30, protective rod 40, first motor 501, first gear 502, second gear 503, connecting plate 504, cylinder 60, brake Disk 701 , fixed rod 702 , socket 703 , fixed ring 704 , first spring 705 , seat body 80 , annular accommodation chamber 801 , bar-shaped protrusion 802 , baffle plate 803 , non-Newtonian flow 804 , and push button switch 90 .

[0029] The safety protection device for lifting the graphite billet of the present embodiment, such as figure 1 As shown, it includes a support and a protective mechanism arranged on the support. The support is a gantry support comprising two vertical support columns 10. The support columns 10 are fixedly connected to the ground, and a fixed plate 20 is fixedly connected to the top of the support column 10. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com