Carriage chassis, carriage assembly comprising carriage chassis and railway dump truck

A technology for carriages and underframes, applied in railway car body parts, railway transportation, railway transportation, etc., can solve problems such as limited resistance to bending deformation and torsional deformation, small vertical section modulus, and deformation of the underframe structure. Achieve the effect of reducing load, simplifying functions and increasing vehicle load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

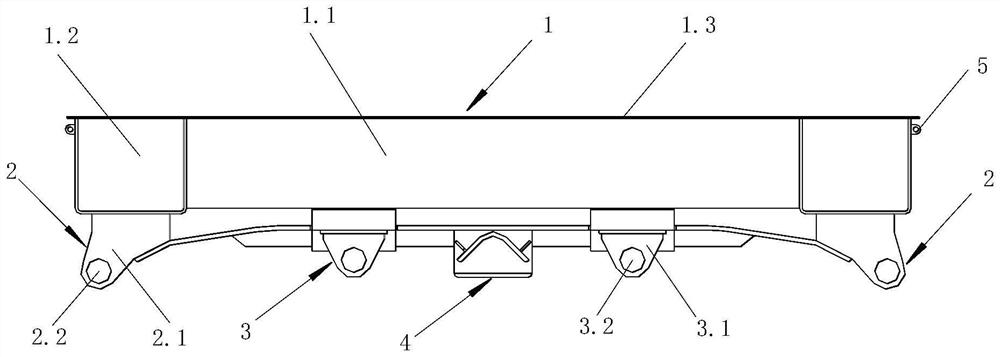

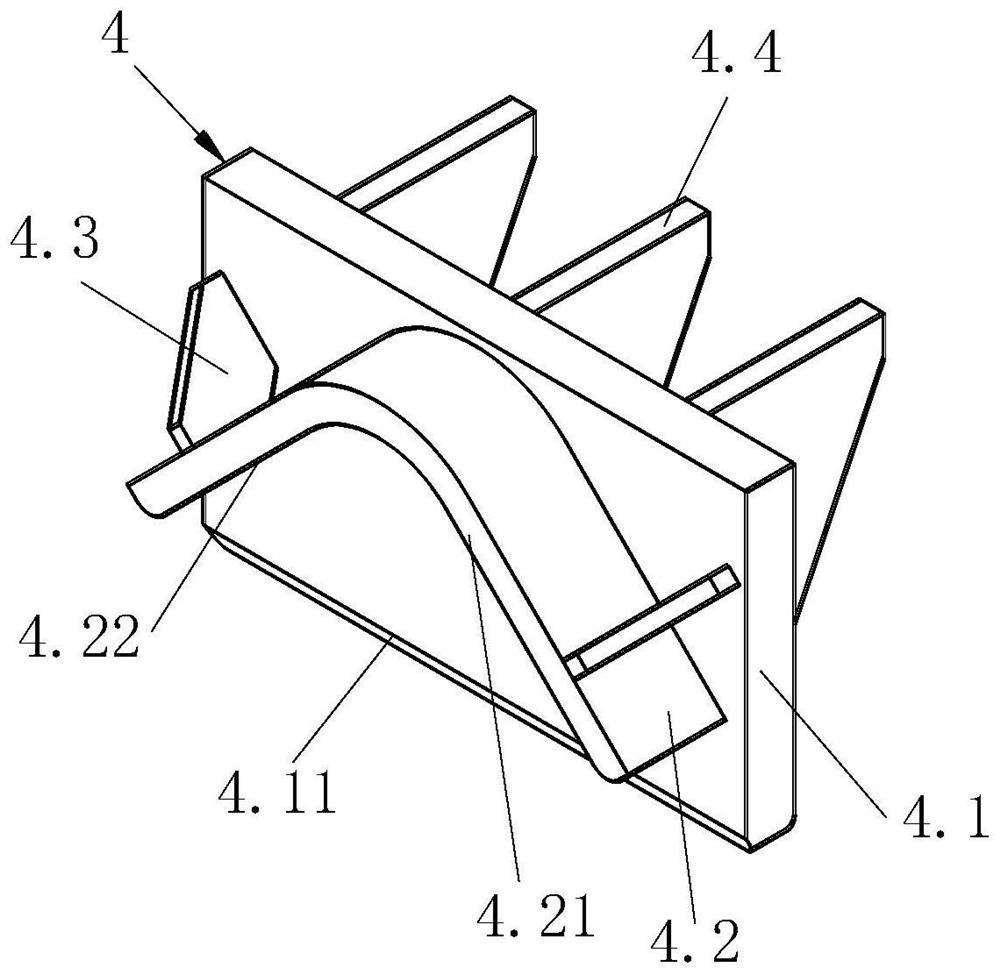

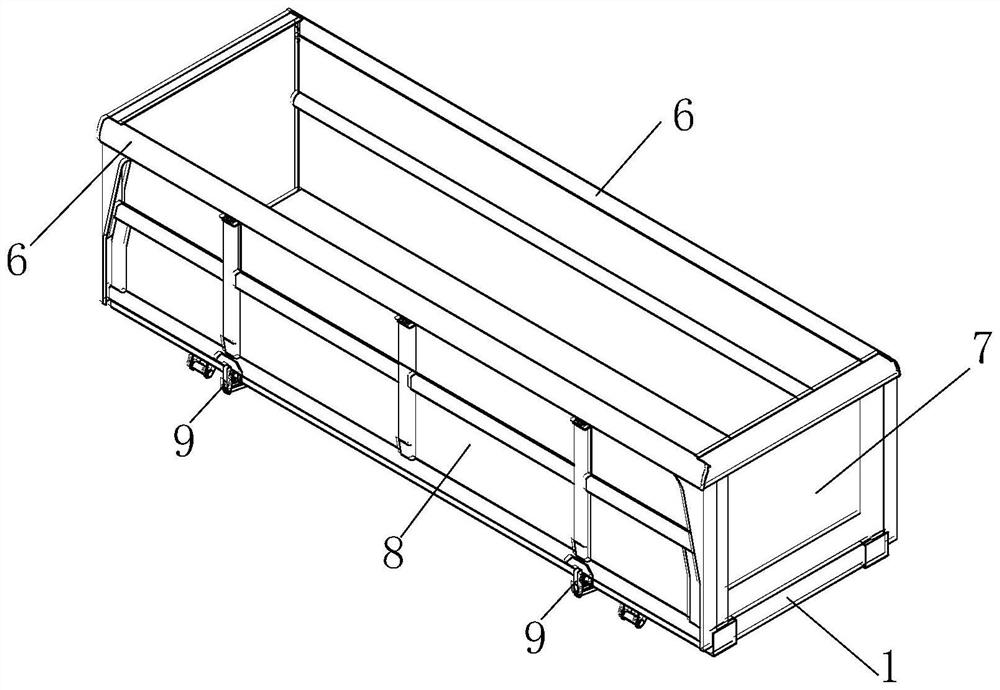

[0040] Such as figure 1 The shown carriage chassis includes a load-bearing frame 1, which is formed by at least two beams 1.1 and at least two side beams 1.2, and the frame formed by the beams 1.1 and the side beams 1.2 is provided with a floor 1.3; At least two outer shaft mechanisms 2 are provided on the bottom of the bearing frame 1, at least two inner shaft mechanisms 3 are arranged between the outer shaft mechanisms 2, and at least one is provided between the inner shaft mechanisms 3 for forming cooperation with the chassis The upper limit block assembly 4 is used to limit the longitudinal and lateral positioning of the chassis of the carriage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com