Thin-gauge alloy steel and production method thereof

A production method and alloy steel technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that restrict the development of thin-gauge low-carbon alloy steel, low-quality single product of thin-gauge products, and scratches on the upper and lower surfaces of steel plates To achieve the effect of improving welding performance and cold and hot processing performance, improving customer use requirements, and easy control of plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

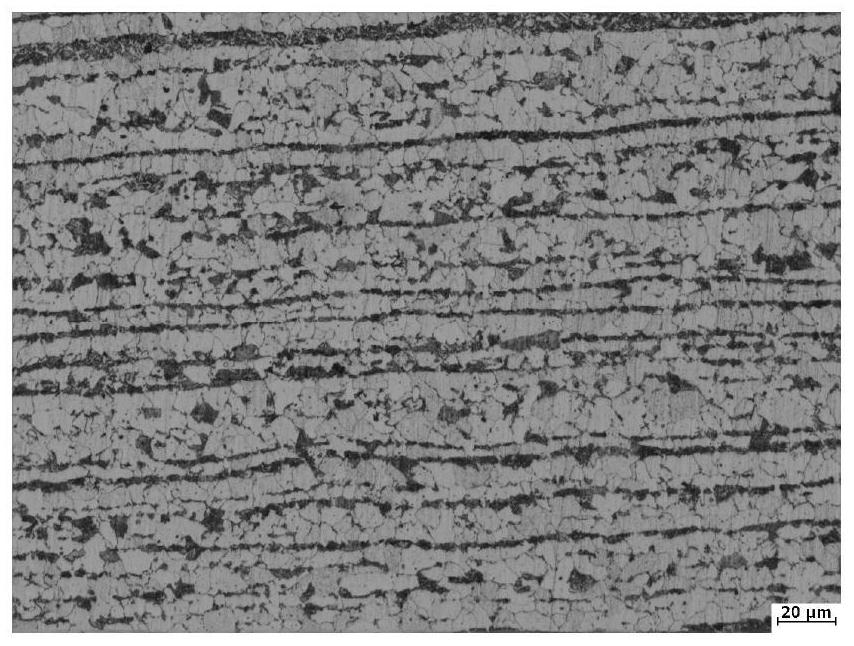

Image

Examples

Embodiment 1

[0024] A thin-gauge alloy steel provided in this example, steel grade Q390C, steel plate thickness 8mm, its chemical composition and mass percentage are as follows: C: 13%, Si: 0.22%, Mn: 1.31%, P: 0.013%, S: 0.009%, Nb: 0.031%, V: 0.002%, Ti: 0.013%, Cr: 0.16%, Ni: 0.02%, Mo: 0.005%, Cu: 0.02%, Al: 0.031%, N: 0.0031%, balance For Fe and unavoidable impurities.

[0025] Its manufacturing method comprises the following steps:

[0026] S1. After desulfurization, molten iron is sent to smelting furnace for smelting, LF deoxidation alloying, vacuum furnace degassing treatment (non-essential process), and sent to continuous casting for casting and casting;

[0027] S2. According to the size of the order, the billet is opened to 63mm. After the billet is opened, it is not watered, and it is cooled for 48 hours. The billet after stacking is purged or peeled according to the order requirements. After surface treatment, groove the lower billet at 2mm around, the groove depth is 2.3mm...

Embodiment 2

[0033] A thin-gauge alloy steel provided in this example, the steel grade is ship plate E460, the thickness of the steel plate is 6mm, and its chemical composition and mass percentage are as follows: C: 0.06%, Si: 0.21%, Mn: 1.61%, P: 0.008% , S: 0.0020%, Nb: 0.033%, V: 0.036%, Ti: 0.016%, Cr: 0.18%, Ni: 0.41%, Mo: 0.003%, Cu: 0.029%, Al: 0.018%, N: 0.0041% , B: 0.0003%, the balance is Fe and unavoidable impurities.

[0034] Its manufacturing method comprises the following steps:

[0035] S1. After desulfurization, molten iron is sent to smelting furnace for smelting, LF deoxidation alloying, vacuum furnace degassing treatment (non-essential process), and sent to continuous casting for casting and casting;

[0036] S2. According to the size of the order, the billet is opened to 68mm. After the billet is opened, it is not watered, and it is cooled for 48 hours. The billet after stacking is purged or peeled according to the order requirements. After surface treatment, groove t...

Embodiment 3

[0042]A thin-gauge alloy steel provided in this example has a steel grade of Q550 and a steel plate thickness of 12 mm. Its chemical composition and mass percentage are as follows: C: 0.13%, Si: 0.27%, Mn: 1.41%, P: 0.013%, S : 0.002%, Nb: 0.029%, V: 0.001%, Ti: 0.019%, Cr: 0.39%, Ni: 0.11%, Mo: 0.20%, Cu: 0.02%, Al: 0.033%, B: 0.0015%, N : 0.0037%, the balance is Fe and unavoidable impurities.

[0043] Its manufacturing method comprises the following steps:

[0044] S1. After desulfurization, molten iron is sent to smelting furnace for smelting, LF deoxidation alloying, vacuum furnace degassing treatment, and sent to continuous casting for casting and casting;

[0045] S2. According to the size of the order, the billet is opened to 68mm. After the billet is opened, it is not watered, and it is cooled for 48 hours. The billet after stacking is purged or peeled according to the order requirements. After surface treatment, groove the lower billet at 2mm around, the groove dept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com