Image-based film mark detection method of scribing machine

A detection method and dicing machine technology, applied in image analysis, image enhancement, image data processing and other directions, can solve the problem of cutting depth relying on manual experience to control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

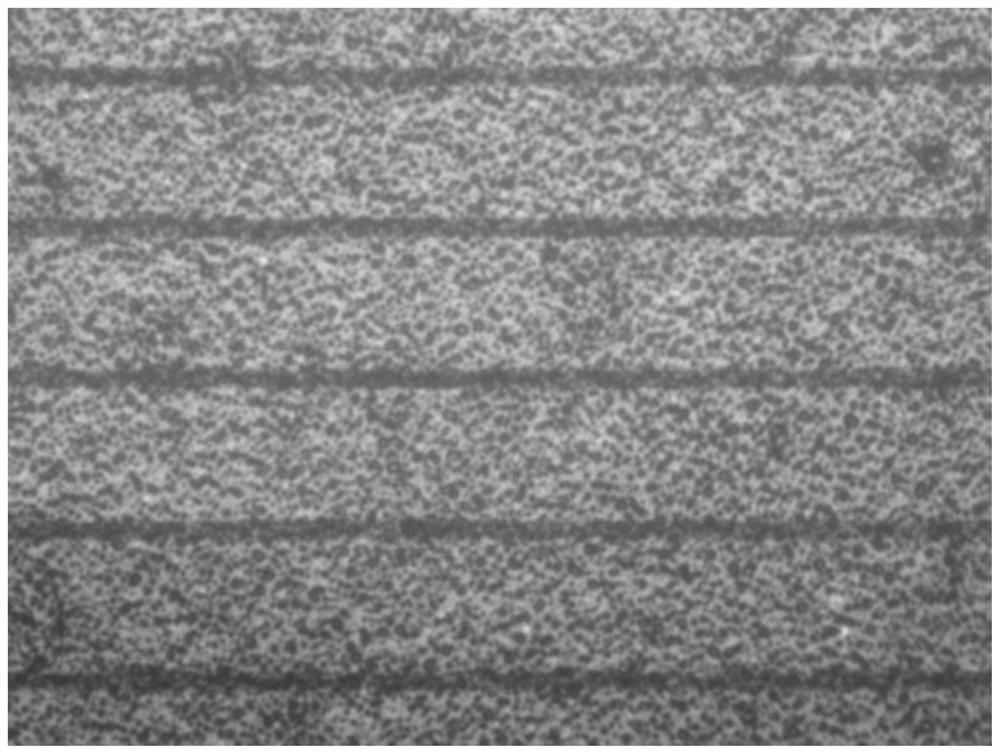

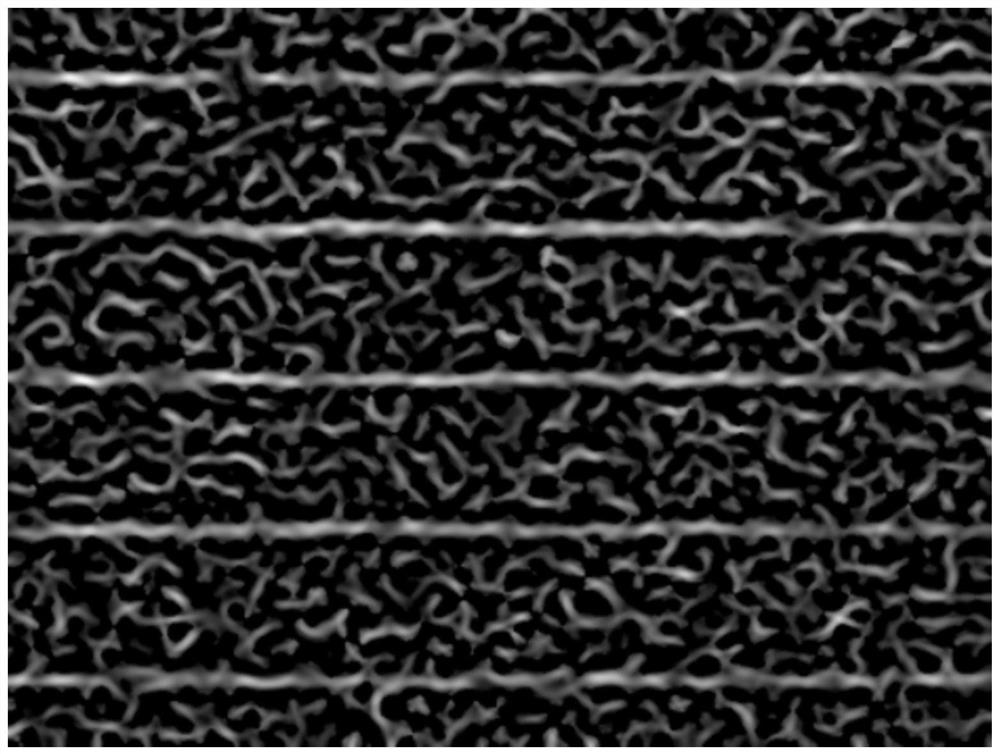

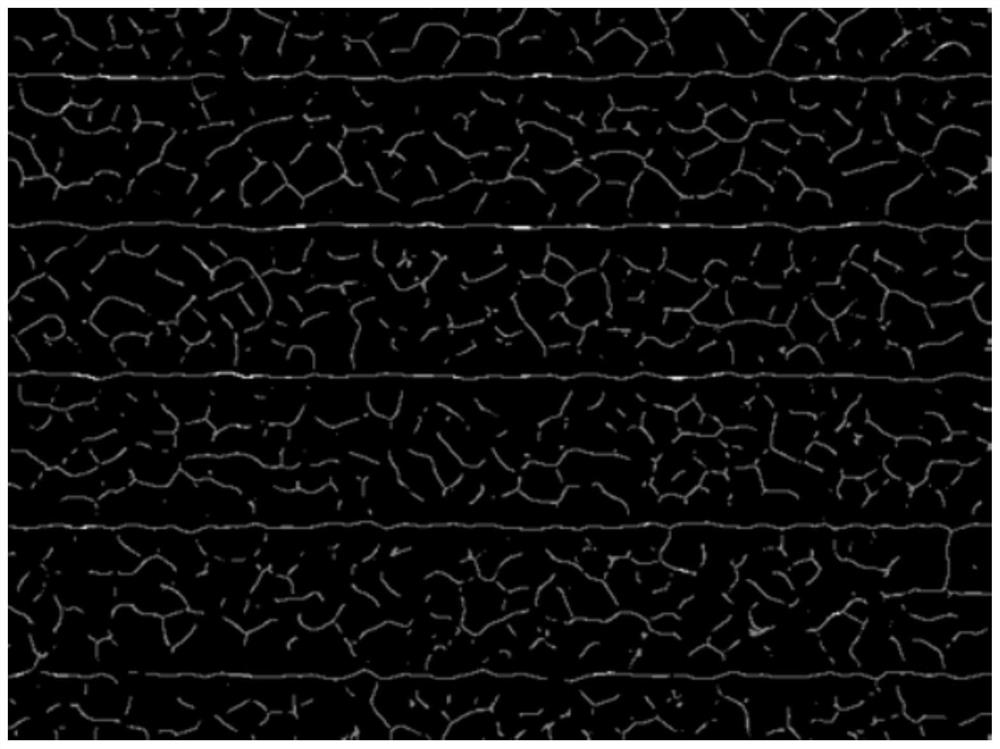

[0035] The detection system of the present invention is based on the motion and image recognition system of the dicing machine. The motion system of the dicing machine is mainly composed of X, Y, Z, and T axes, wherein the T axis represents the rotation axis, and there is a workbench on it. The T axis is fixed on the X axis, and the X axis can move left and right. The microscope is fixed on the Y axis, and the Y axis can move forward and backward. The Z axis is fixed on the Y, and can move up and down. The detection system cooperates with the software algorithm to realize the discrimination of the presence or absence of film marks and the calculation of the corresponding width. The algorithm first calculates the first-order partial derivative and the second-order partial derivative of the image, and then calculates the precise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com