Flow battery stack liquid guide plate structure and application

A technology of liquid flow battery and liquid guide plate, which is applied in the direction of fuel cells, regenerative fuel cells, circuits, etc., to avoid material damage and improve the reliability of stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

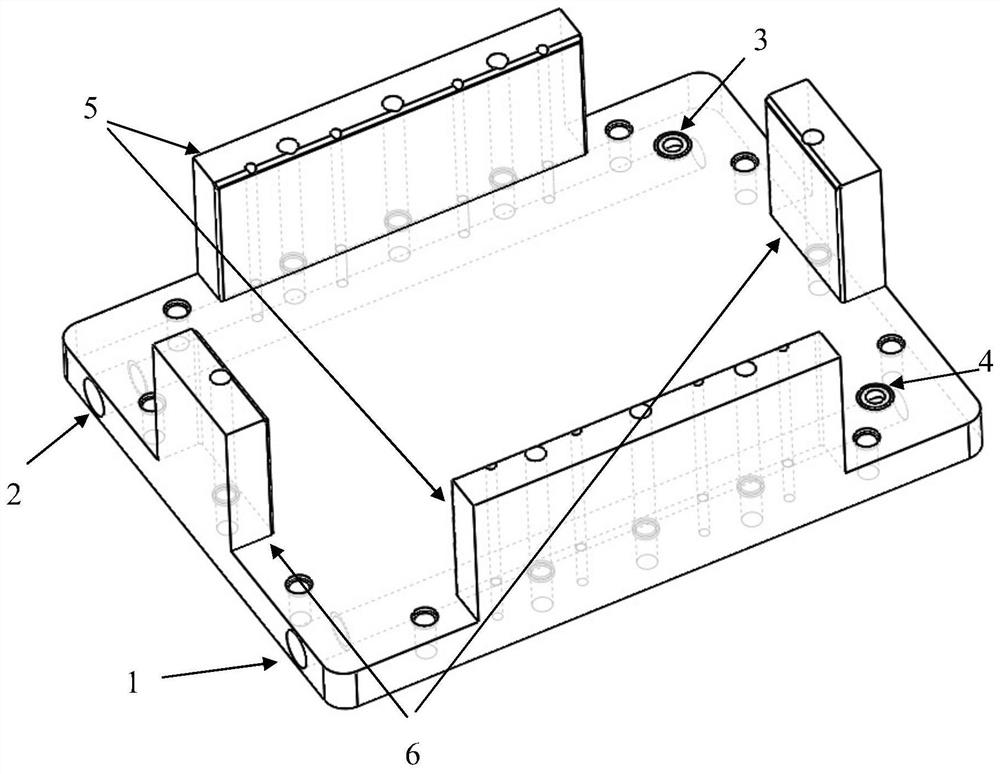

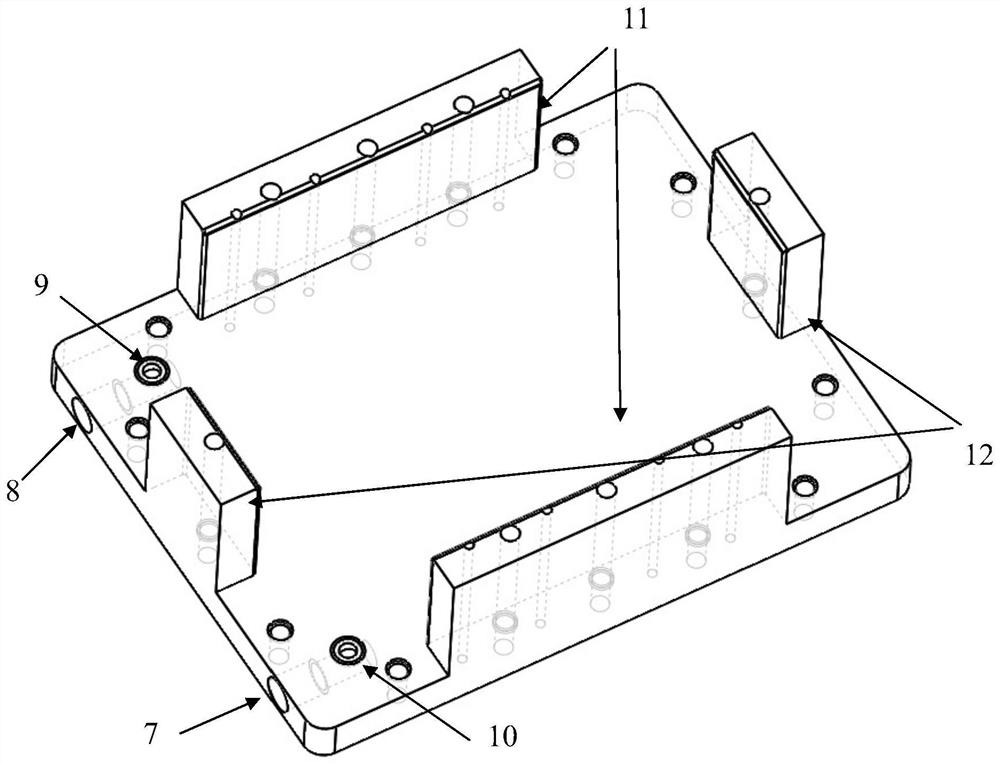

[0034] A stack structure of a liquid flow battery, which consists of aluminum or steel metal end plates on both sides of the stack, figure 1 with figure 2 The matching PVC liquid guide plates A1 and B1, copper collector plates and several single cells are connected in series. Among them, the positive electrolyte flows into the stack through the positive electrolyte inlet 1, and then flows into the positive electrolyte inlet 4 on the electrode frame from the positive electrolyte distribution port 4 flowing into the electrode frame, flows through the electrodes of each single cell, and then aggregates through the outflow electrodes The positive electrolyte distribution port 10 of the frame flows into the liquid guide plate, and then flows out of the stack through the positive electrolyte outlet 7; the negative electrolyte flows into the stack through the negative electrolyte inlet 2, and then flows into the negative electrolyte distribution port 3 of the electrode frame Flow i...

Embodiment 2

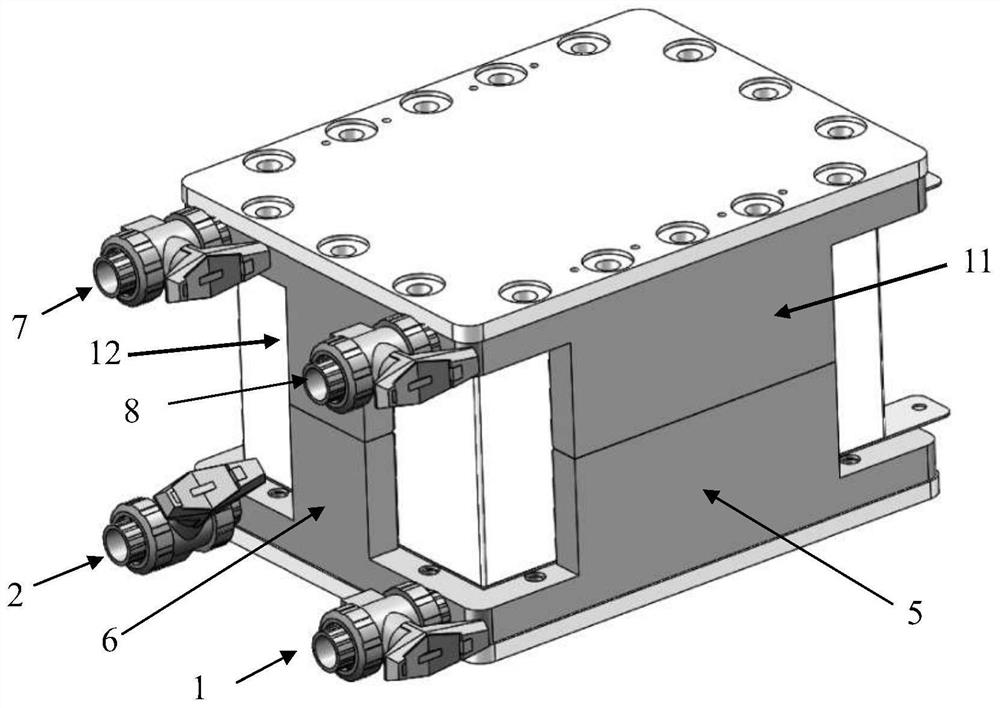

[0041] A stack structure of a liquid flow battery, which consists of aluminum or steel metal end plates on both sides of the stack, Figure 4 with Figure 5 The matching PVC liquid guide plates A2 and B2, copper current collector plates and several single cells are connected in series. Among them, the positive electrolyte flows into the cell stack through the positive electrolyte inlet 1, and then flows into the positive electrolyte liquid inlet port 4 on the electrode frame from the positive electrolyte distribution port 4 flowing into the electrode frame, and flows through the electrodes of each single cell before being aggregated. The positive electrode electrolyte distribution port 10 flowing out of the electrode frame flows into the liquid guide plate, and then flows out of the stack through the positive electrode electrolyte outlet 7; the negative electrode electrolyte flows into the stack through the negative electrode electrolyte inlet 2, and then the negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com