Patents

Literature

31results about How to "Avoid material damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

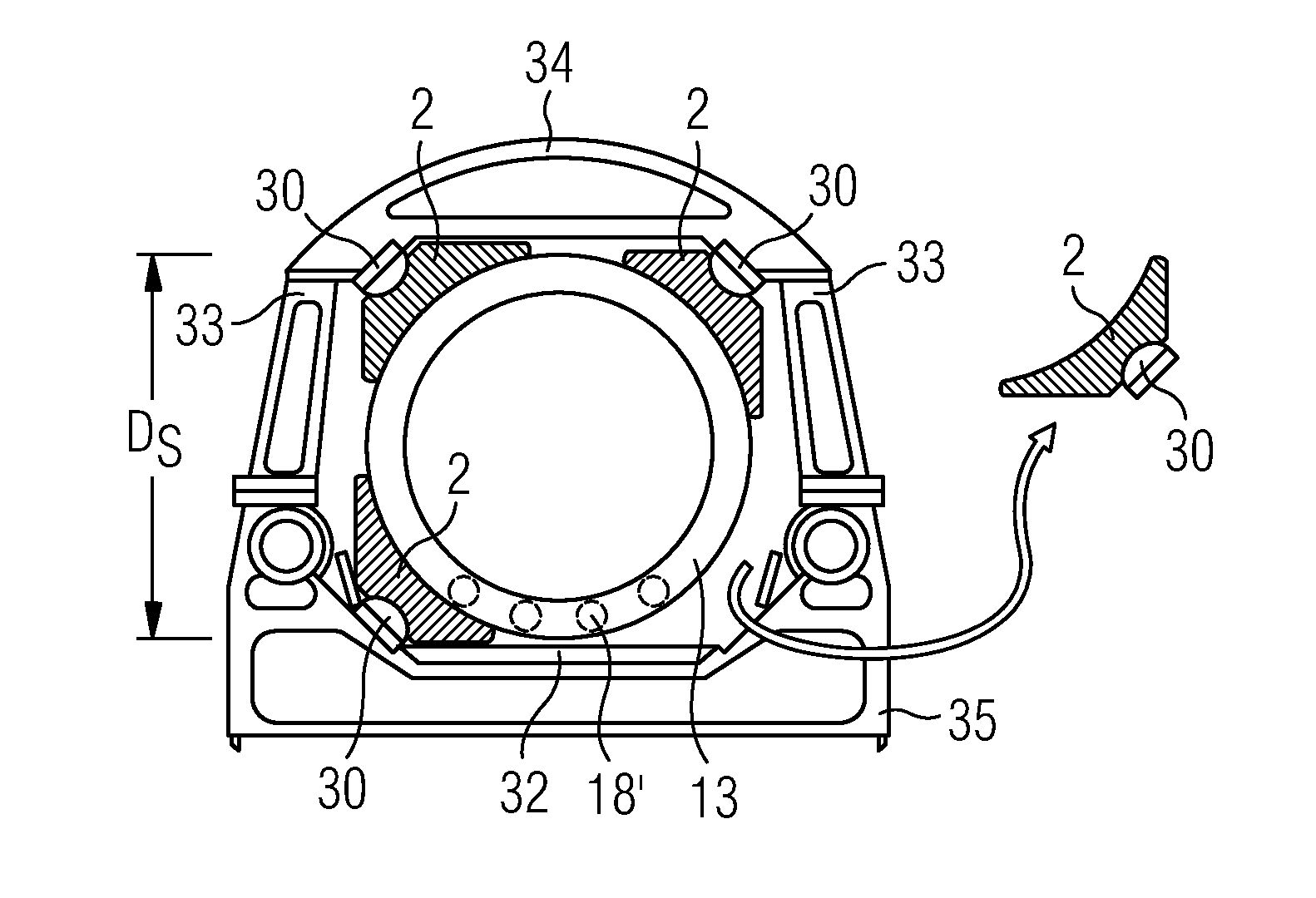

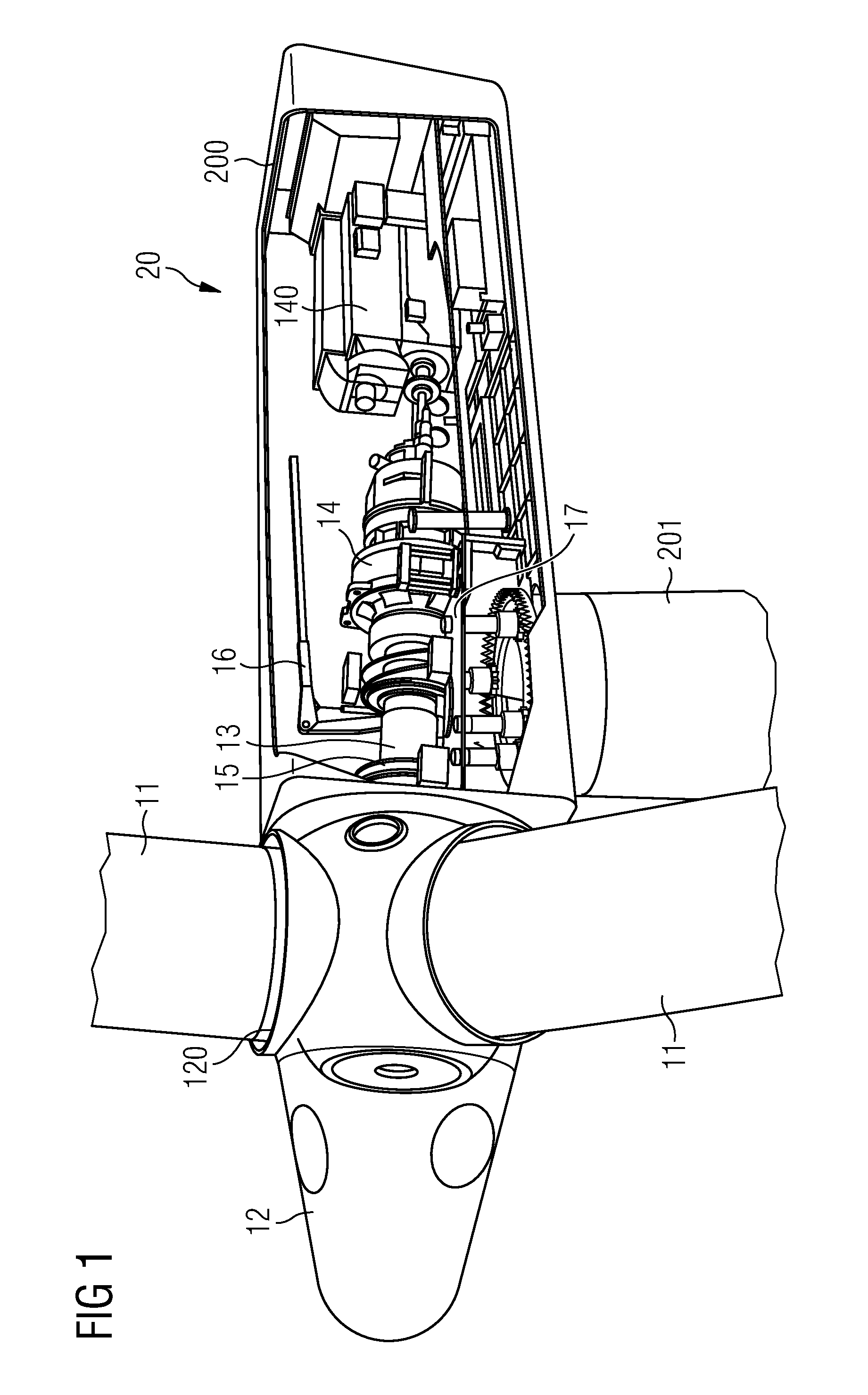

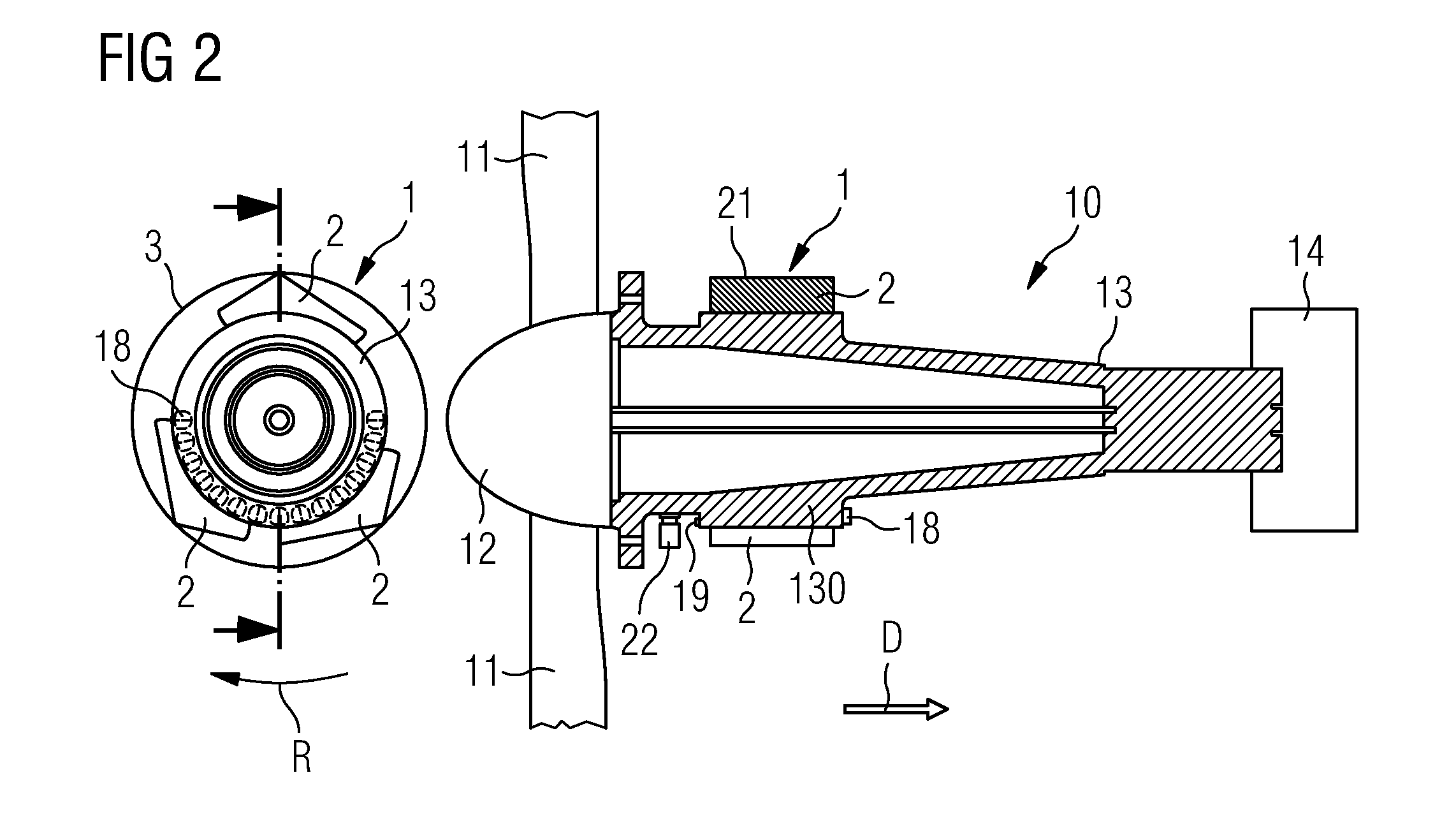

Wind turbine main bearing

ActiveUS20120099993A1Reduce loadEasy to removeBearing repair/replacementPropellersTurbineFluid bearing

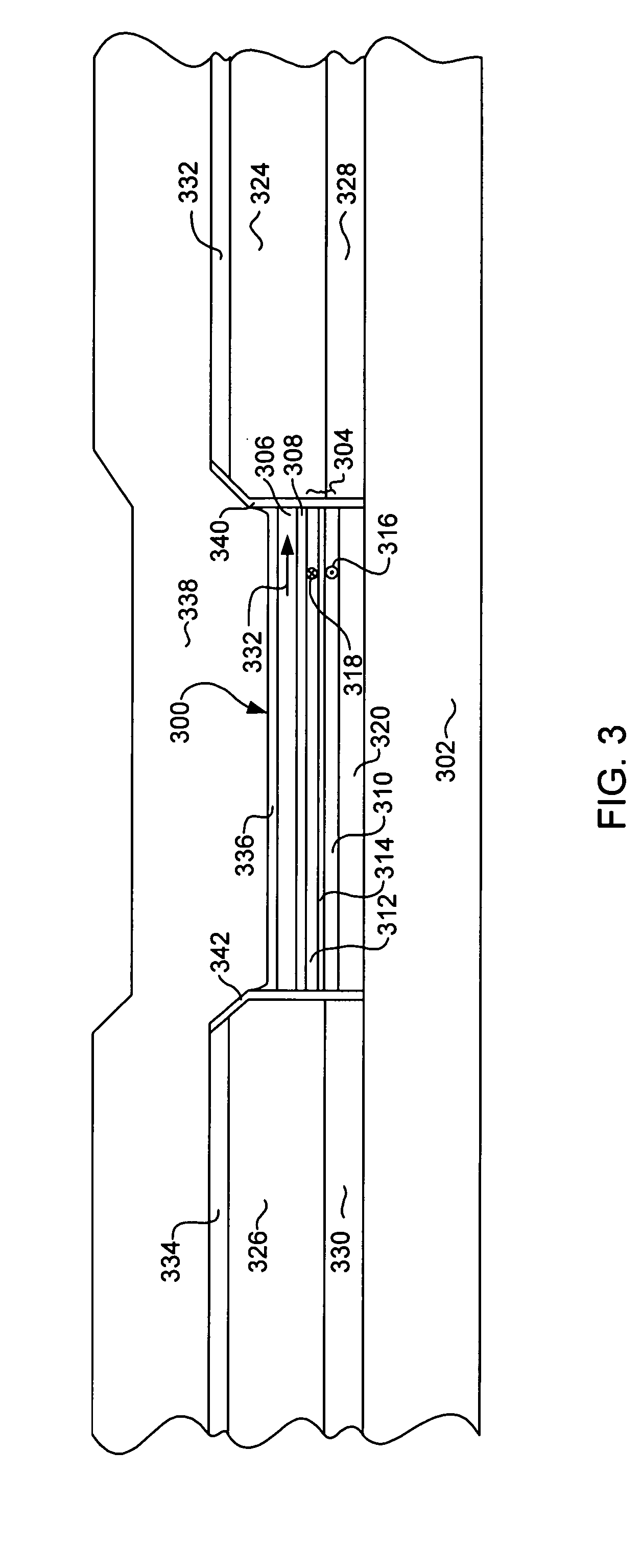

A wind turbine main bearing realized to bear a shaft of a wind turbine, which shaft is caused to rotate by a number of blades connected to the shaft is disclosed. The wind turbine main bearing includes a fluid bearing with a plurality of bearing pads arranged about the shaft. Also disclosed is a wind turbine with a number of blades connected to a shaft and realized to rotate the shaft, which wind turbine includes as main bearing a wind turbine main bearing. Further described is a method of performing maintenance on a wind turbine, including the steps of halting a rotation of the shaft, operating a lifting arrangement to raise the shaft, and removing a bearing pad of the wind turbine main bearing from the bearing housing of the wind turbine main bearing.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

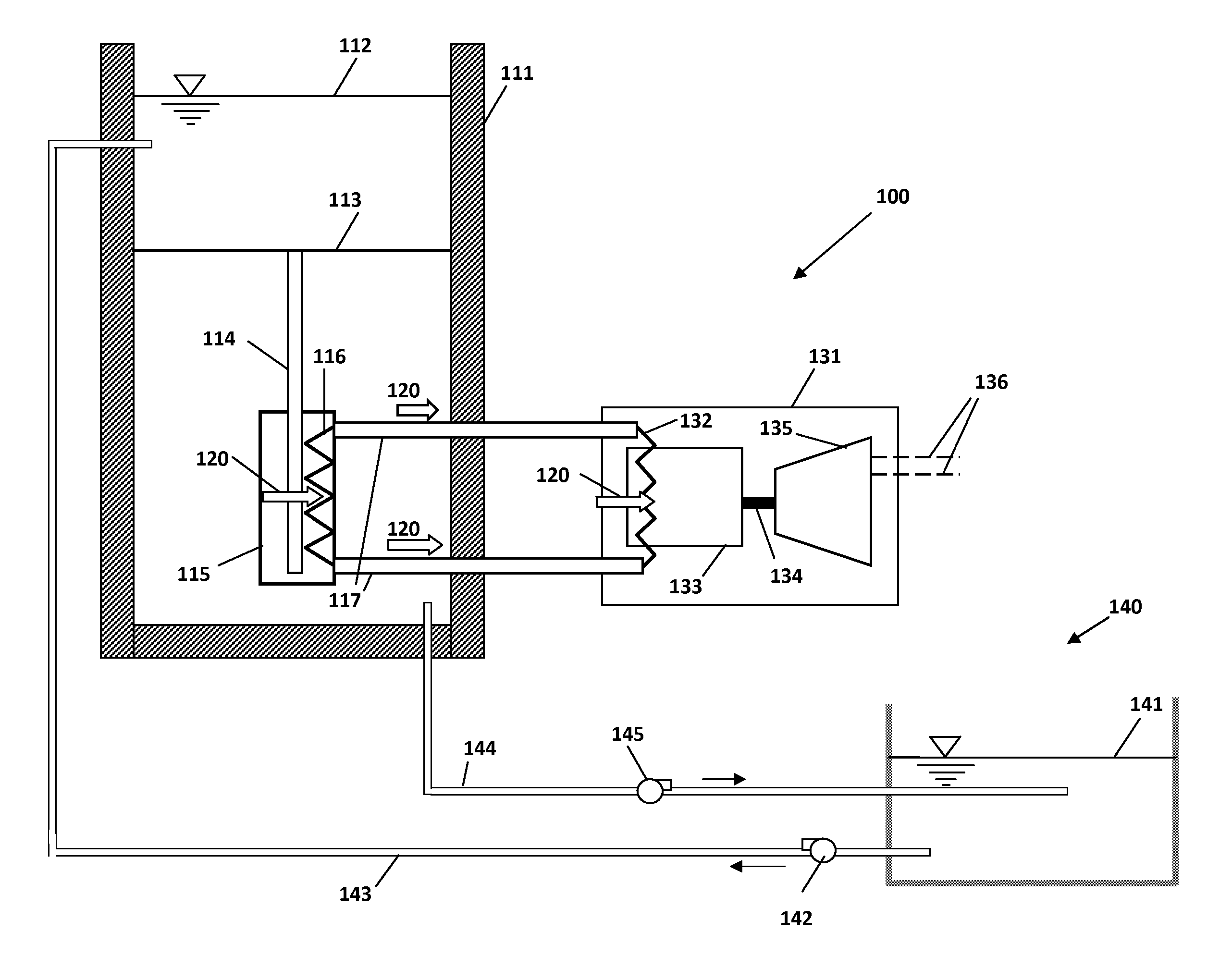

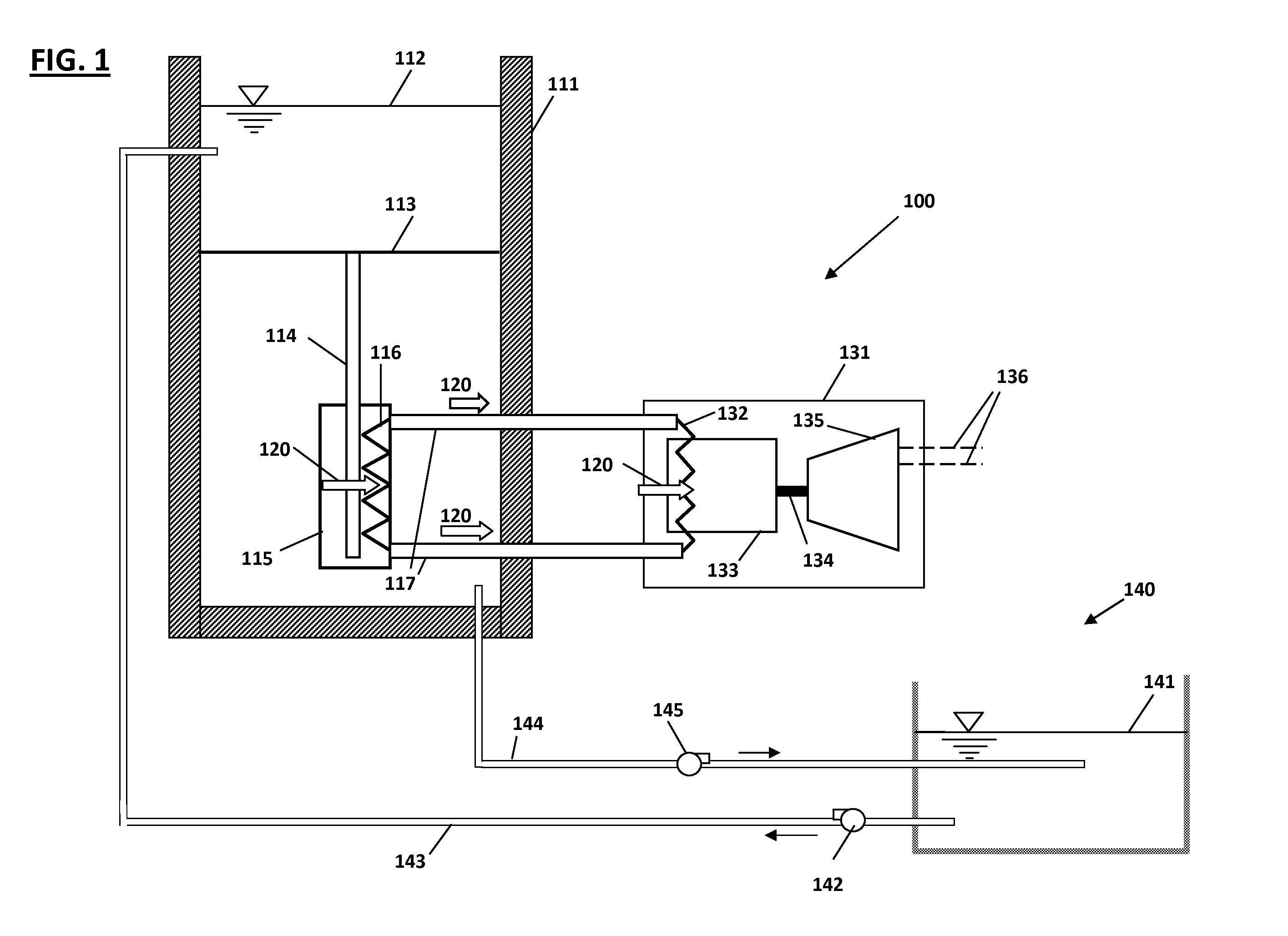

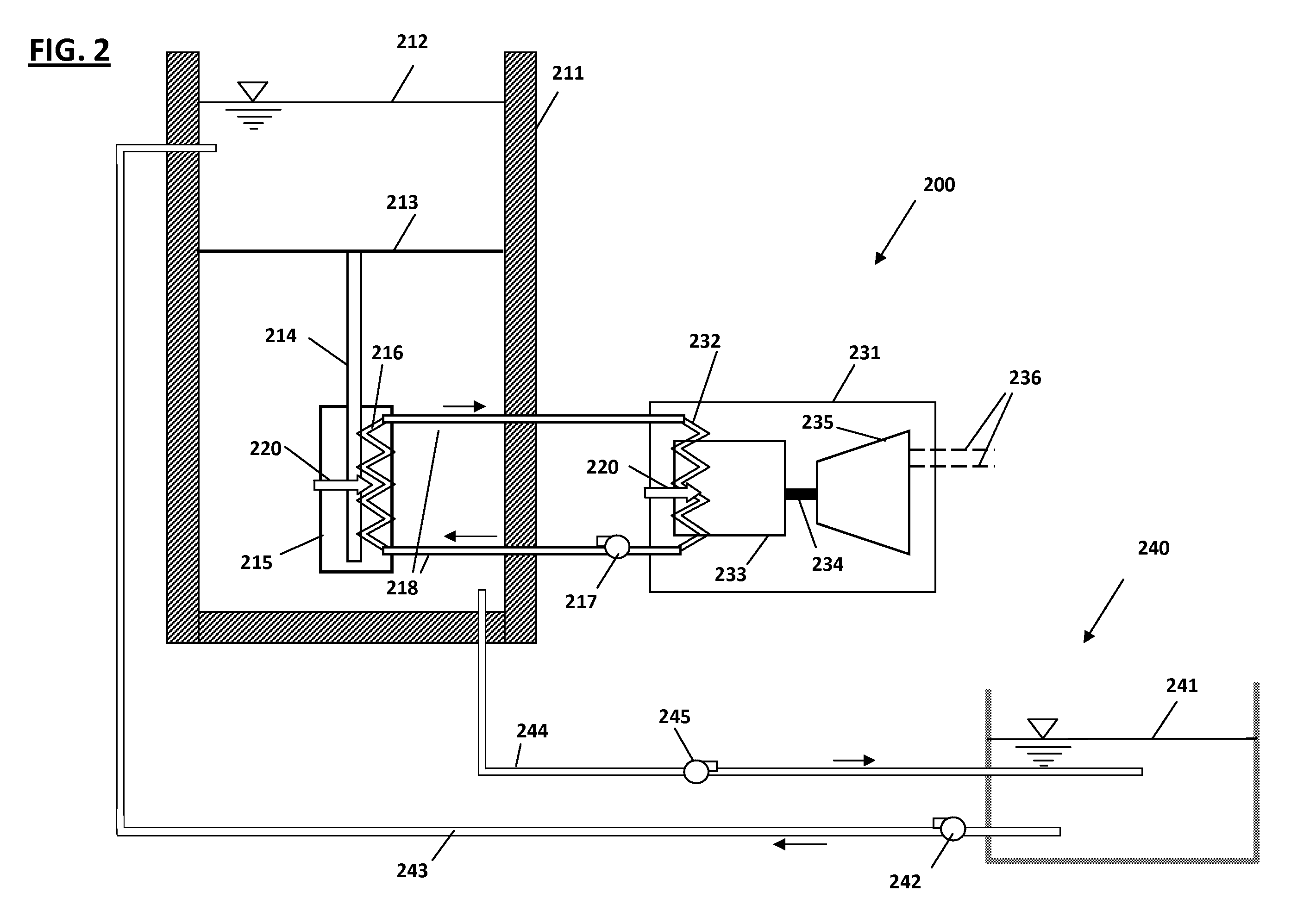

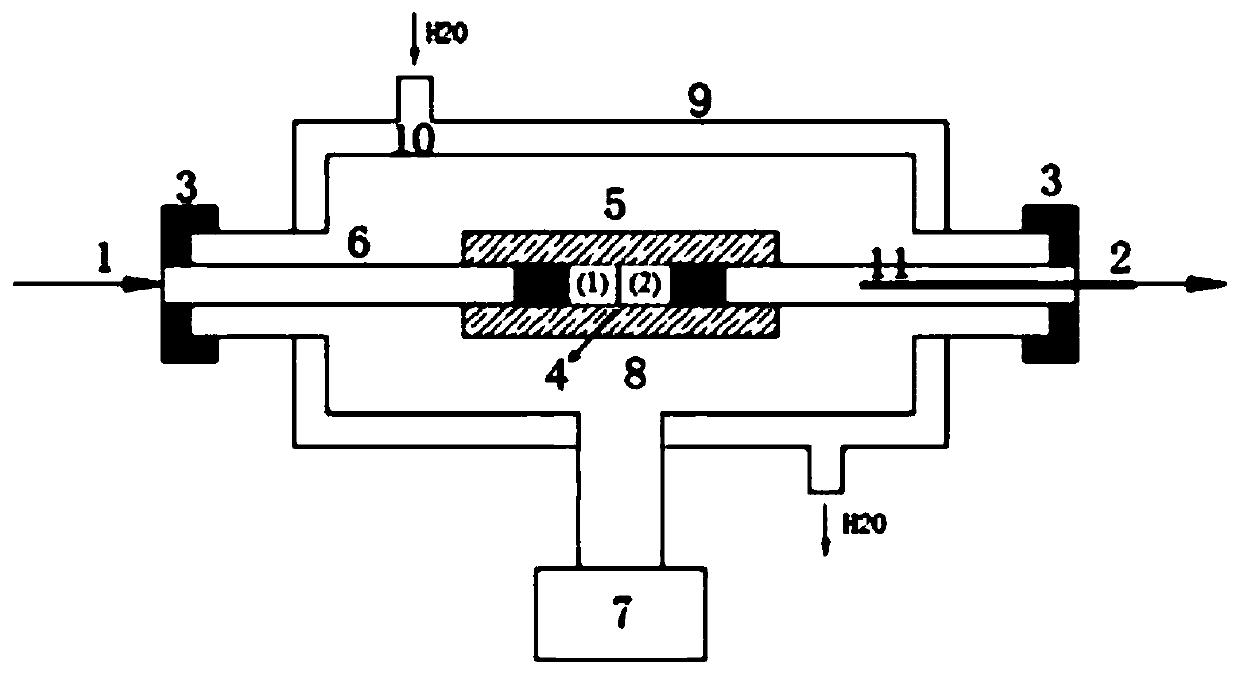

Self Powered Cooling

InactiveUS20110283701A1Immune from external power outageAvoid material damageNuclear energy generationReactor heat to mechanical energyThermal energyTransport system

An apparatus that harnesses the thermal energy of spent fuel rods in nuclear power plants to power the cooling system of the nuclear power plant particularly the cooling for the spent fuel rod storage ponds and the main reactors. The apparatus is comprised of a heat exchanger unit that accumulates the thermal energy of the spent fuel rods, a heat conveyance system that conveys the thermal energy of the spent fuel rods, and a heat engine that receives its thermal energy input from the spent fuel rods and produces mechanical power that runs an electrical generator which powers the cooling system of the nuclear power plant, particularly the controls and pumps that cool the spent fuel rod storage ponds and the main reactors. The apparatus provides a redundant power source and makes the cooling system of nuclear power plants independent of externally supplied electrical power and thereby resolves a key redundancy and safety concern with nuclear power generation. The apparatus also has application to other industries.

Owner:EFTEKHARZADEH SHAHRIAR

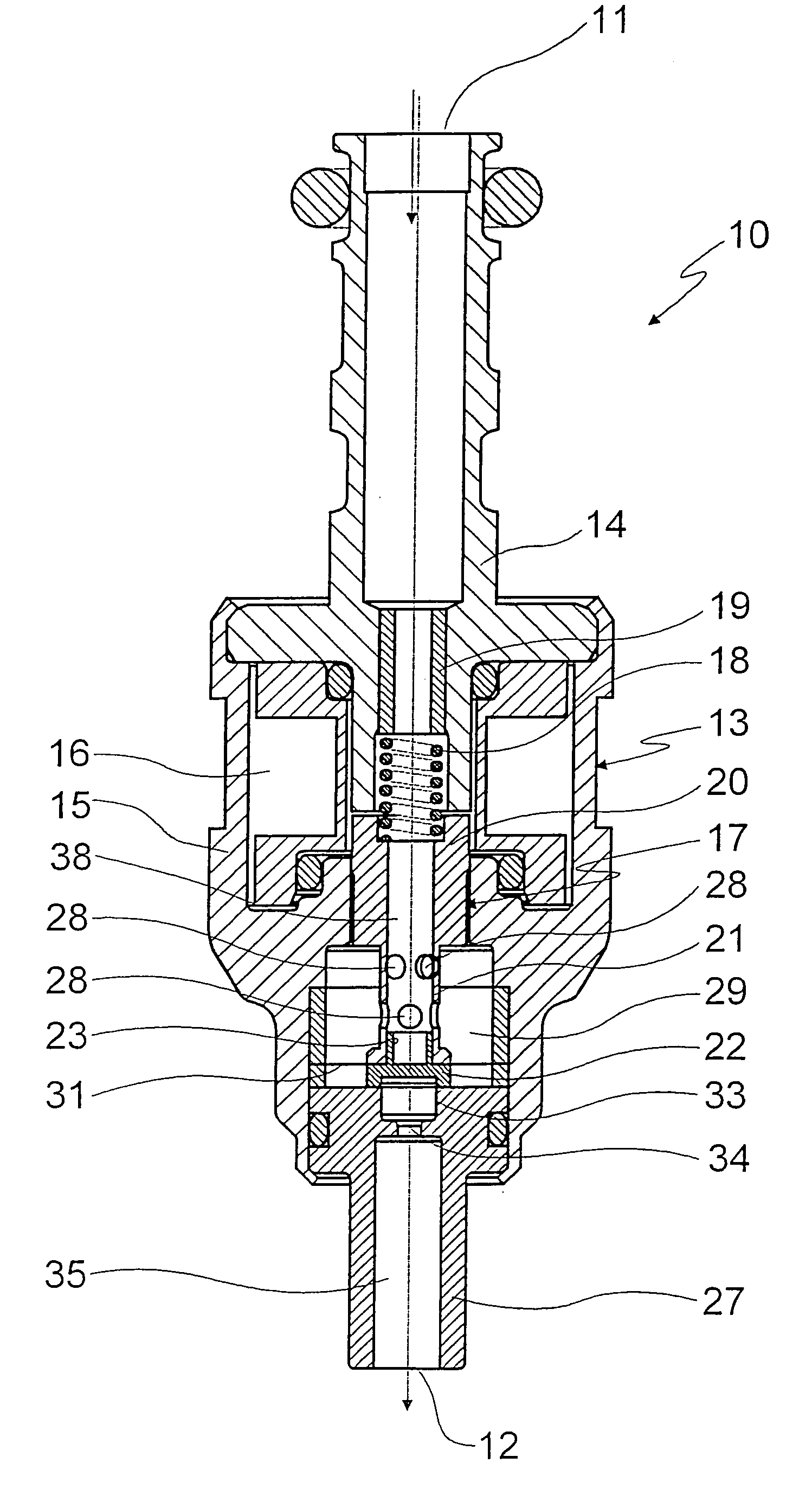

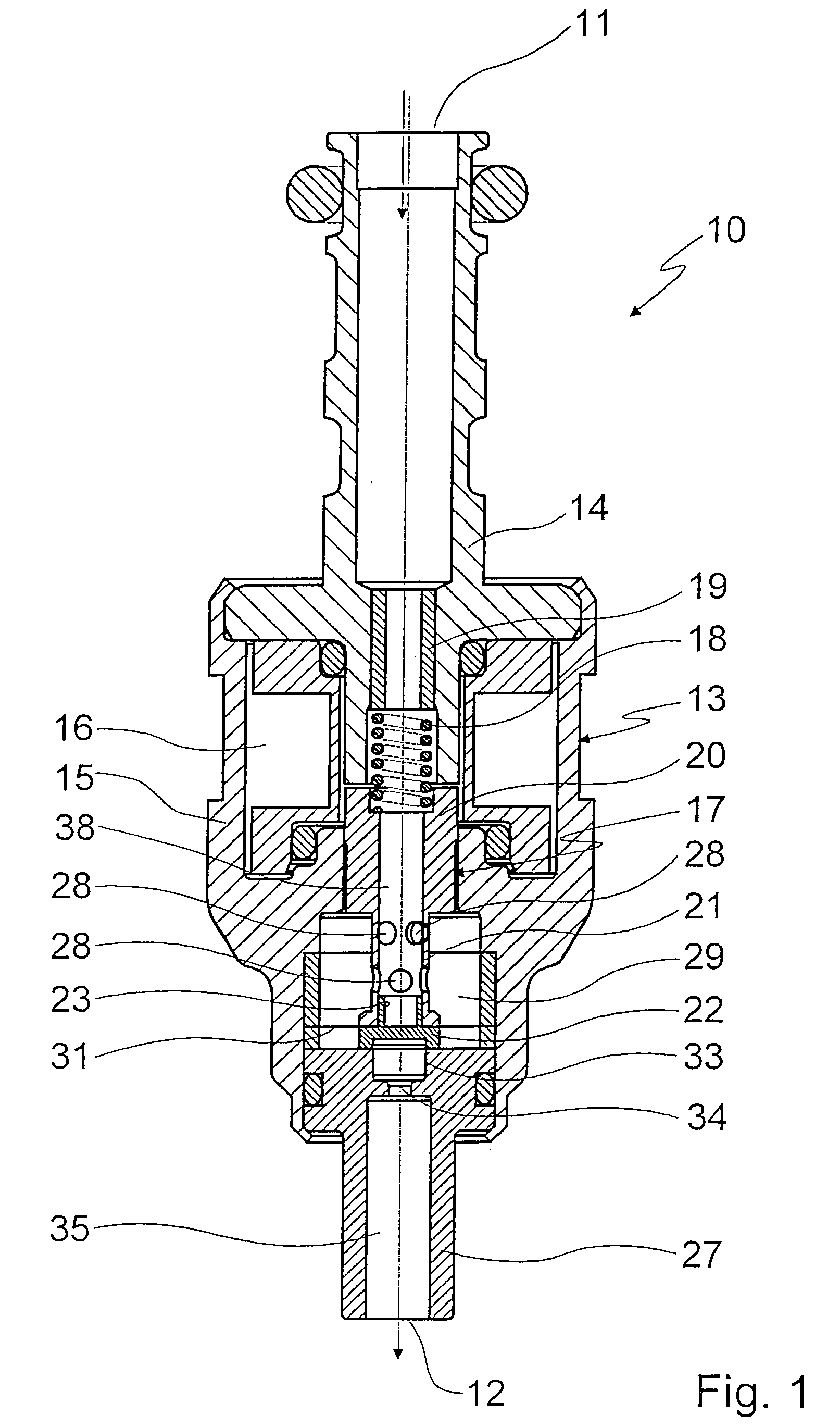

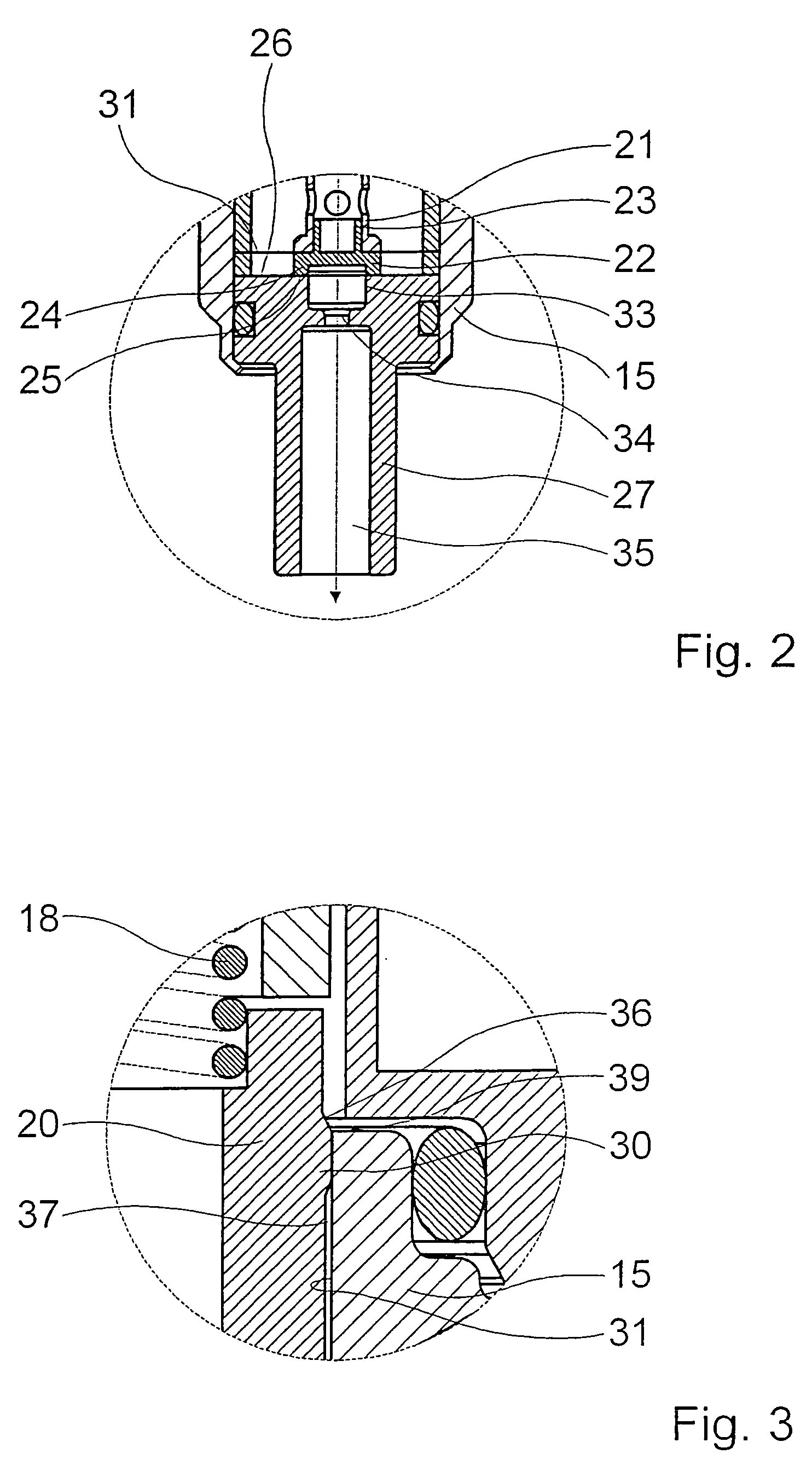

Valve for controlling a fluid

InactiveUS20060231785A1Inhibit transferReduce noiseOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringVALVE PORT

A valve for controlling a fluid, in particular for controlling a gas, is described, encompassing a valve housing an actuation unit for an at least locally tubular valve armature which is guided axially displaceably and is equipped with a valve closure member by which a fluid flow between an inflow side and an outlet side is controllable and which coacts with a valve seat. The valve armature comprises a guidance collar in a region remote from the valve closure member, and is equipped with a second guidance in a region offset with respect to the guidance collar.

Owner:ROBERT BOSCH GMBH

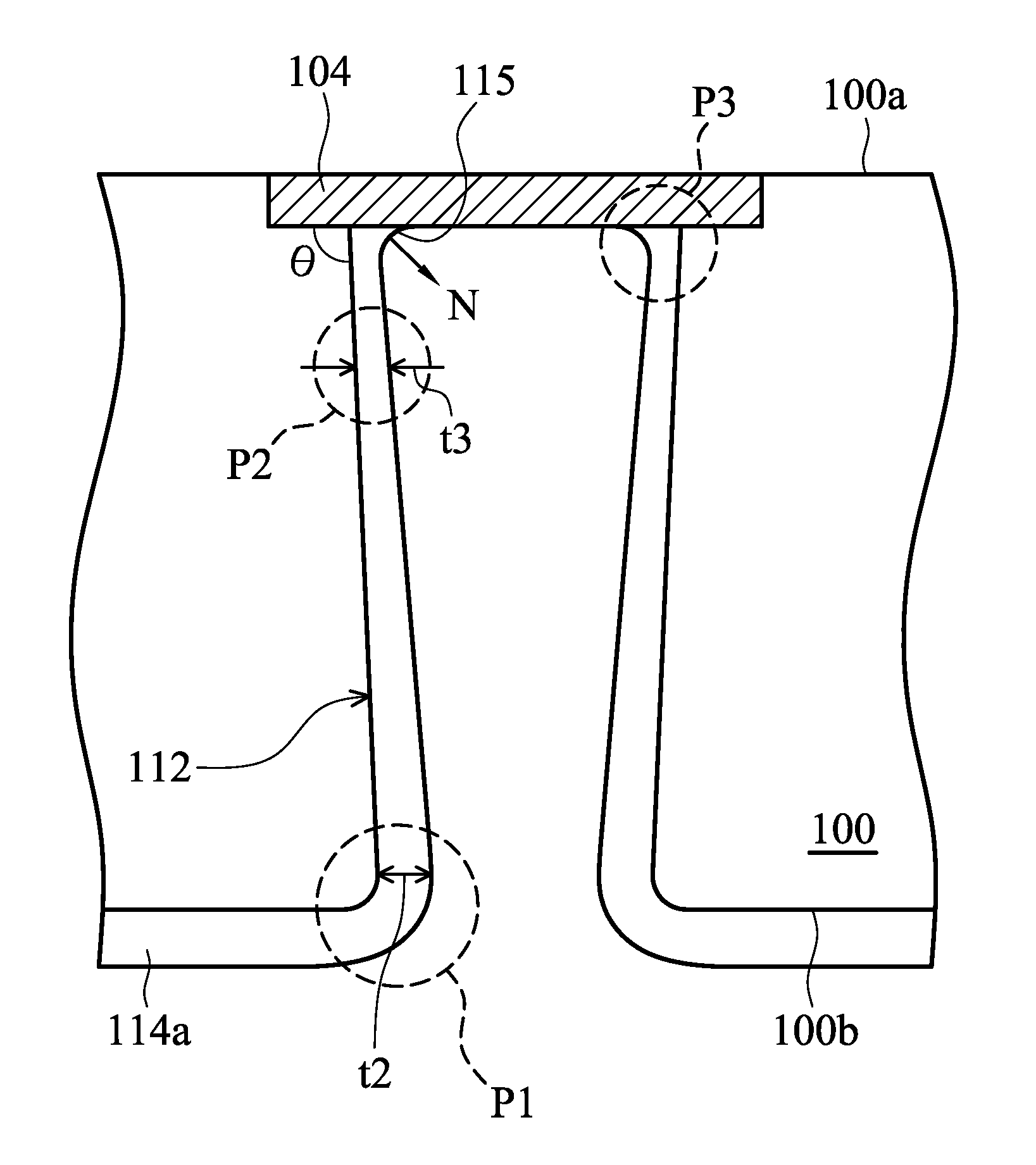

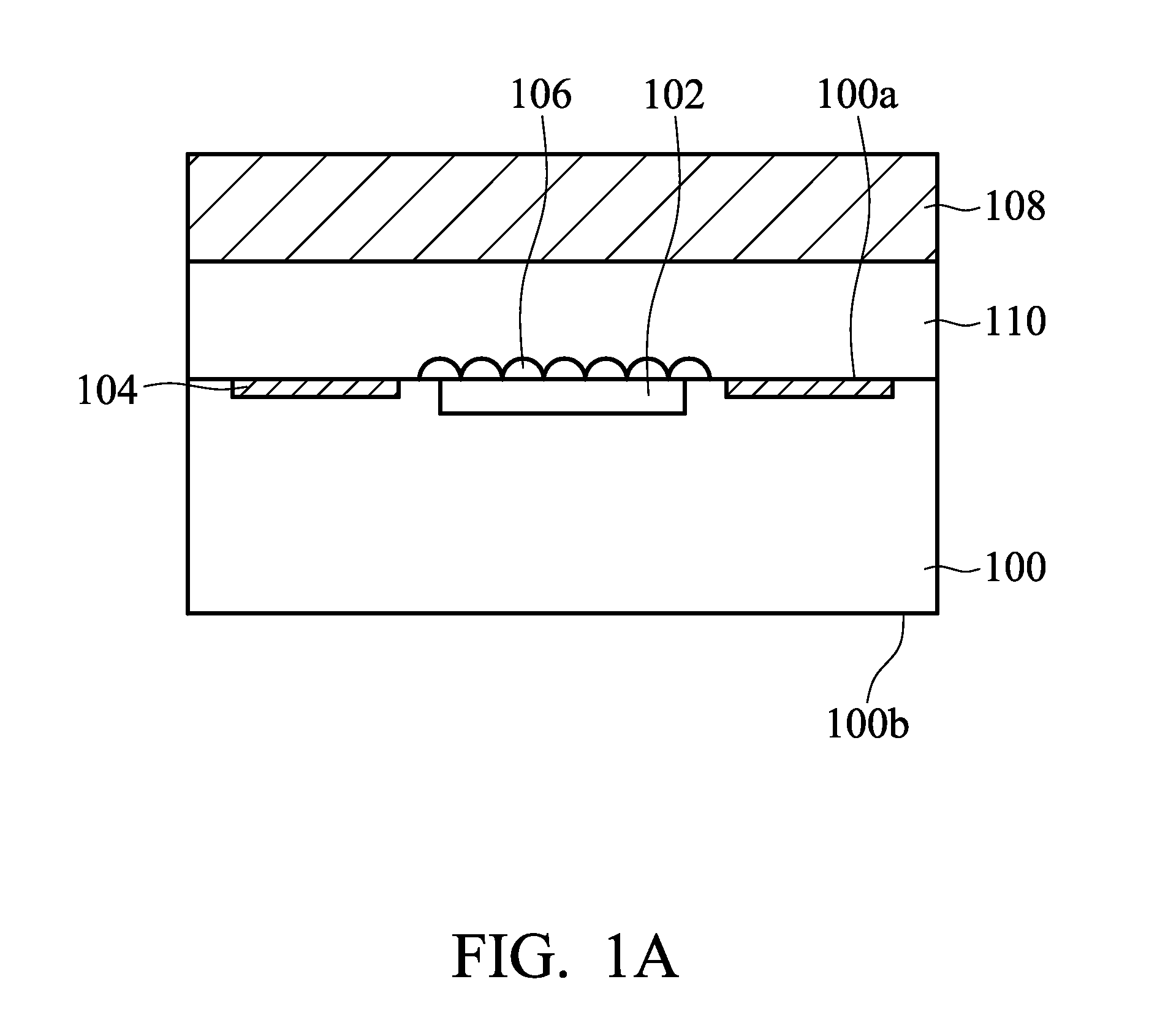

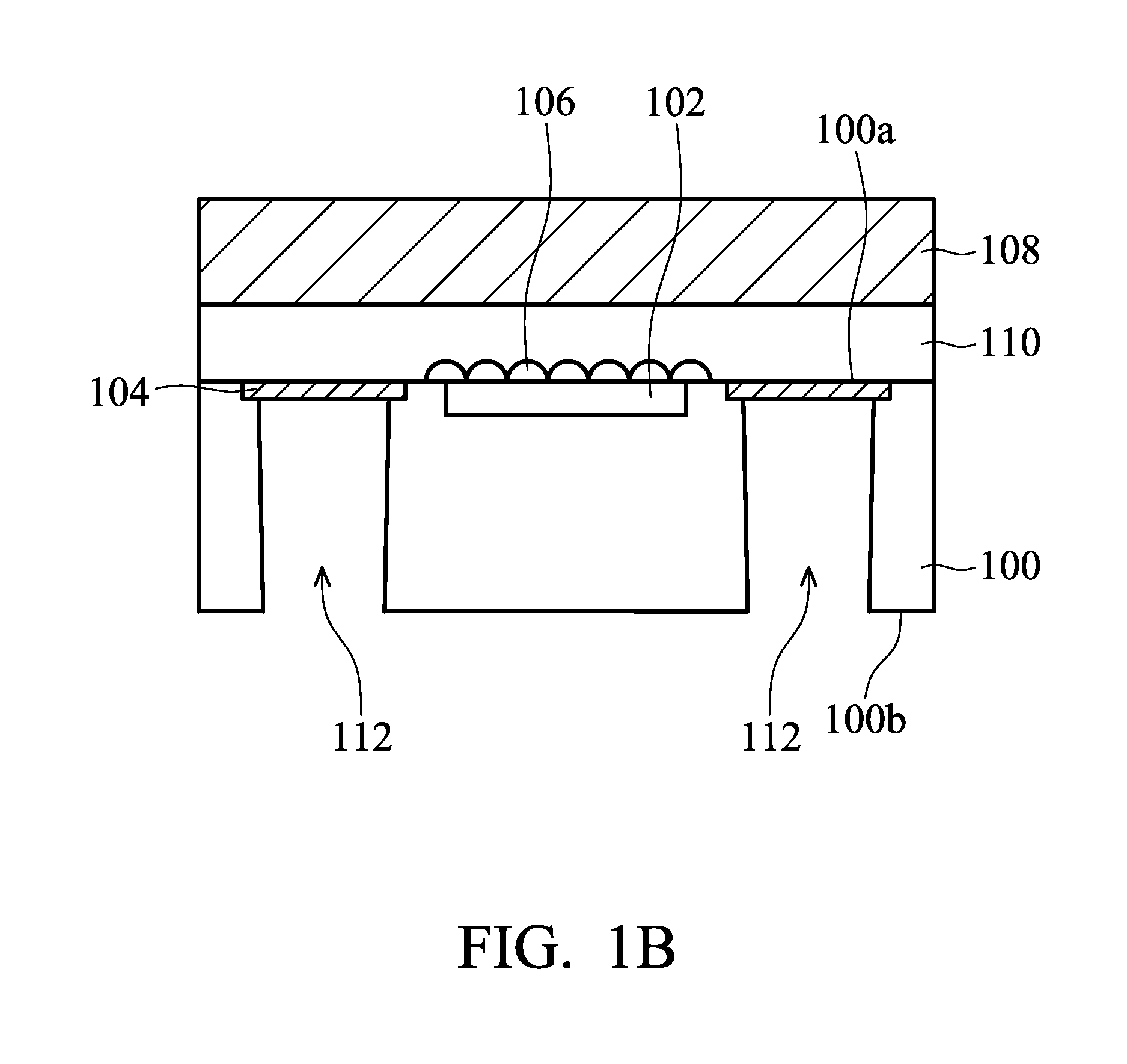

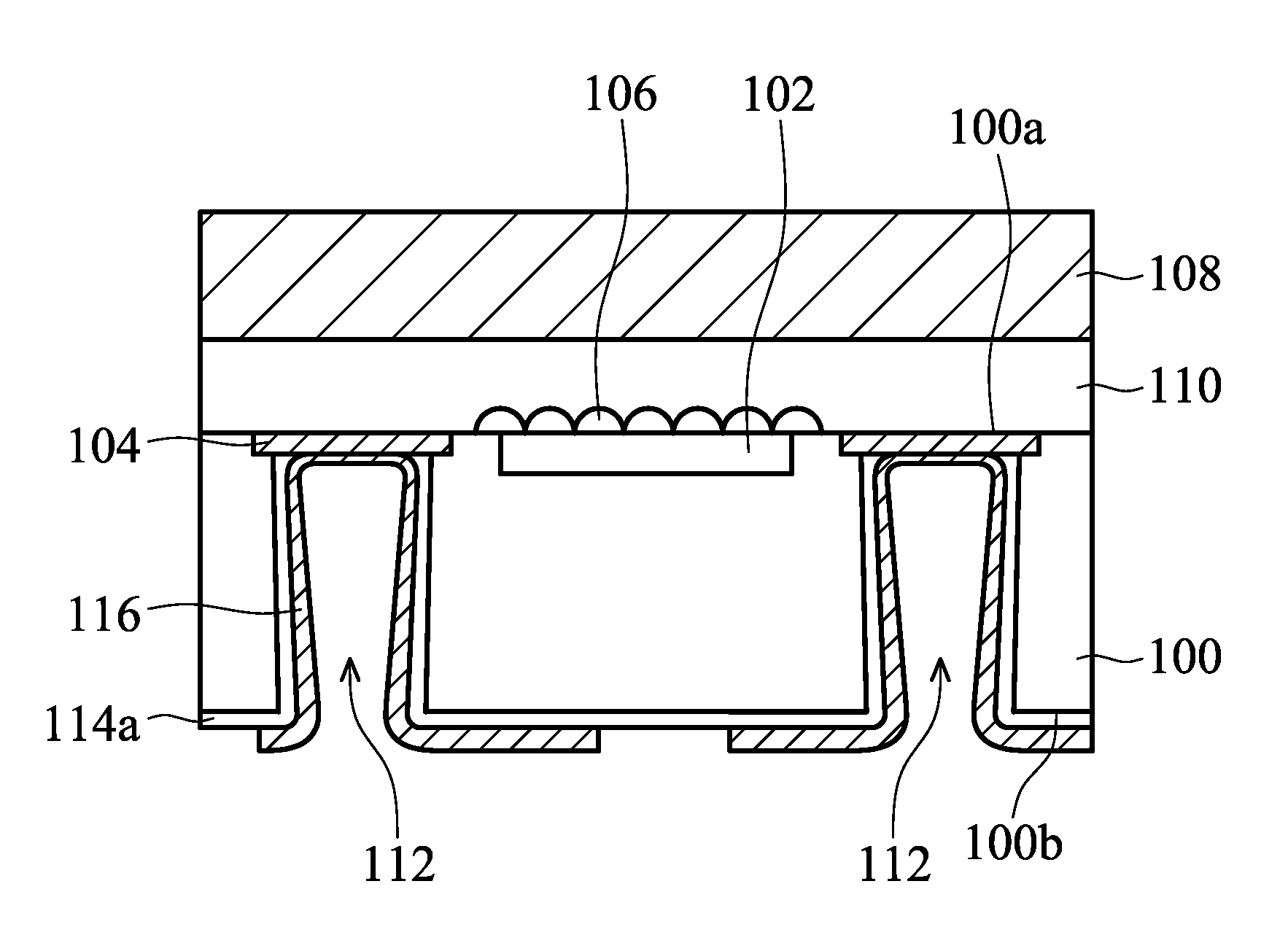

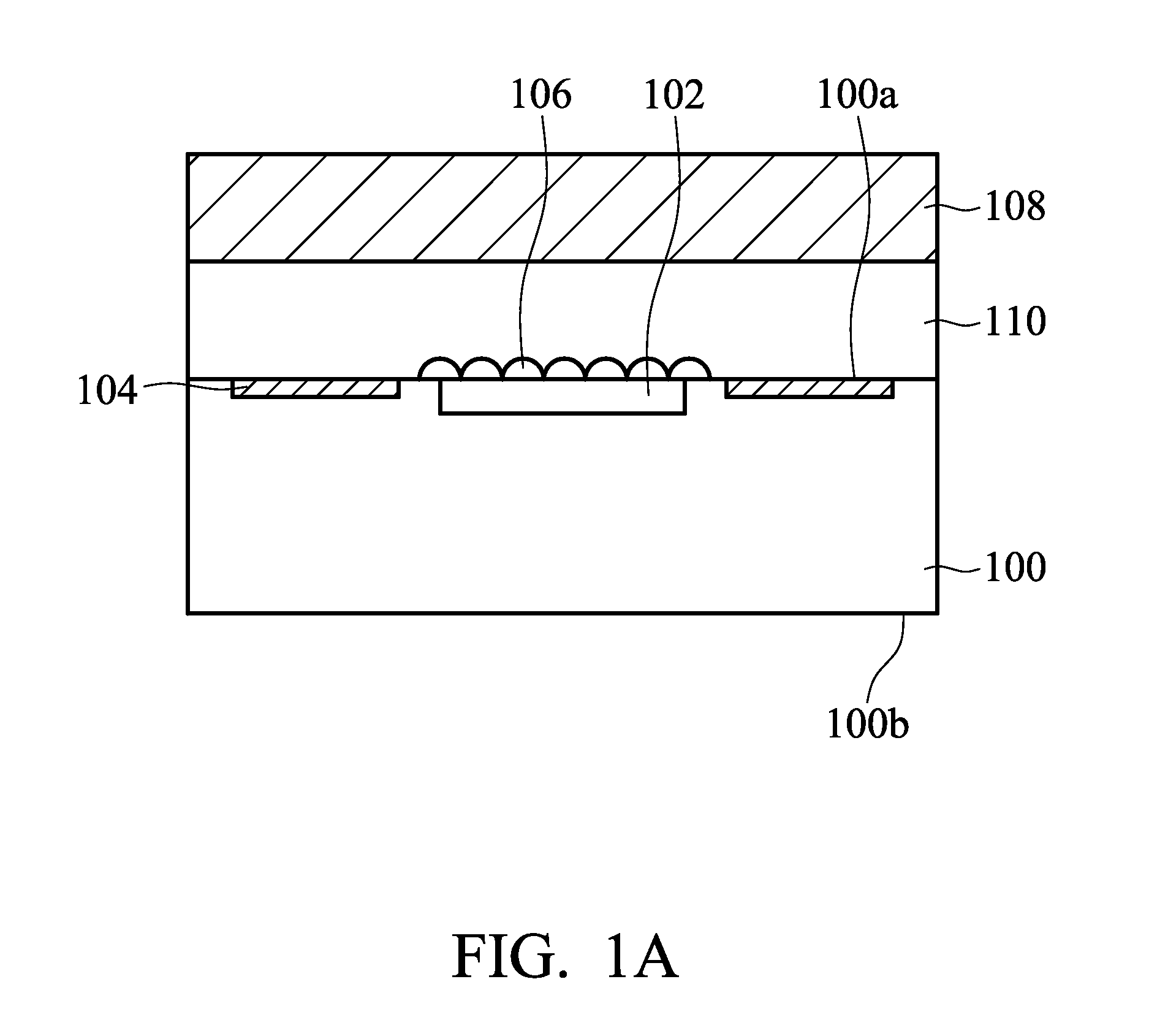

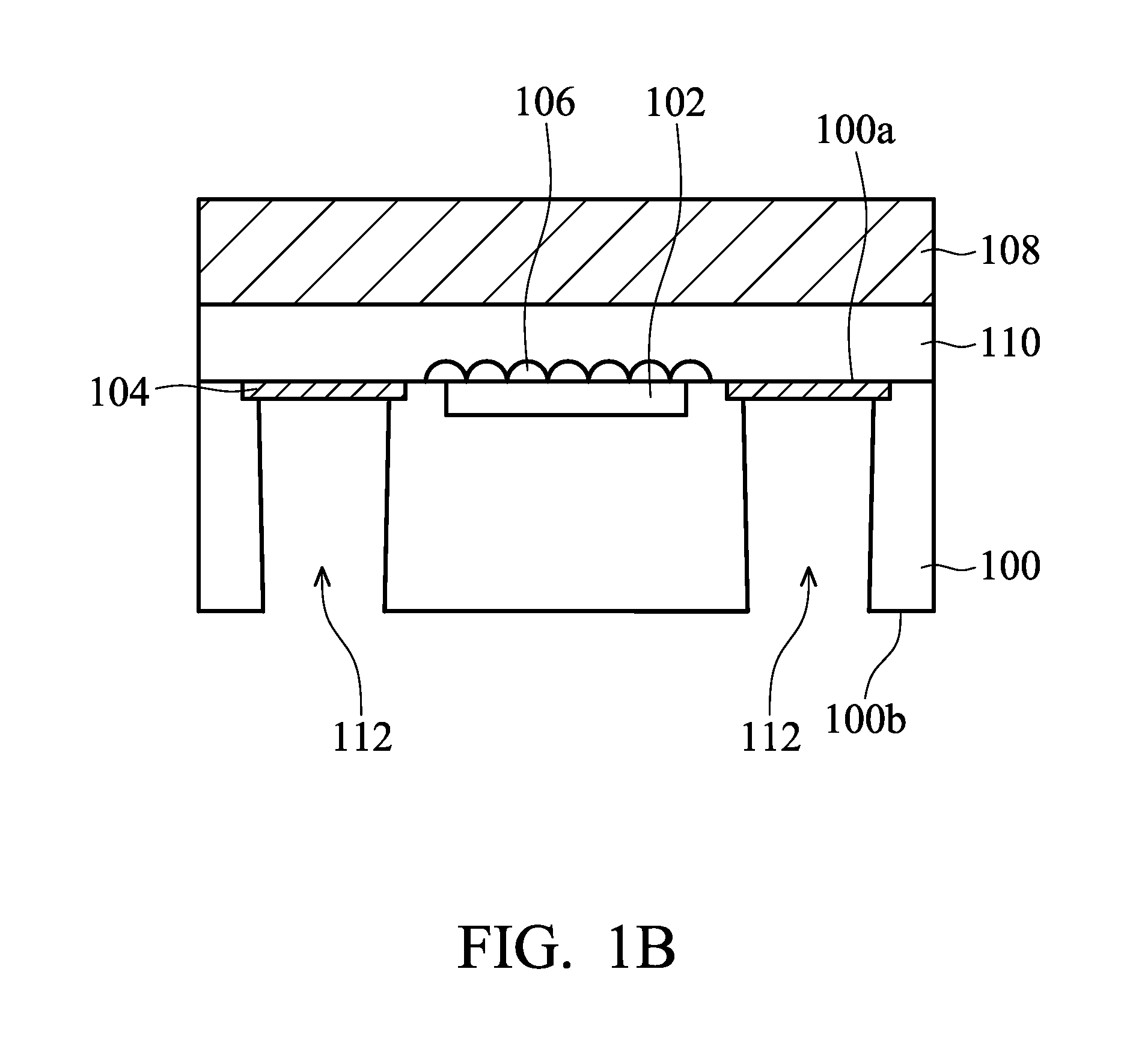

Chip package and method for fabricating the same

ActiveUS20110175236A1Improves yield and reliabilityMuch successSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringEngineering

An embodiment of the invention provides a chip package, which includes a substrate having an upper surface and a lower surface, a chip disposed in or on the substrate, a pad disposed in or on the substrate and electrically connected to the chip, a hole extending from the lower surface toward the upper surface, exposing the pad, wherein a lower opening of the hole near the lower surface has a width that is shorter than that of an upper opening of the hole near the upper surface, an insulating layer located overlying a sidewall of the hole, and a conducting layer located overlying the insulating layer and electrically connected to the pad.

Owner:XINTEC INC

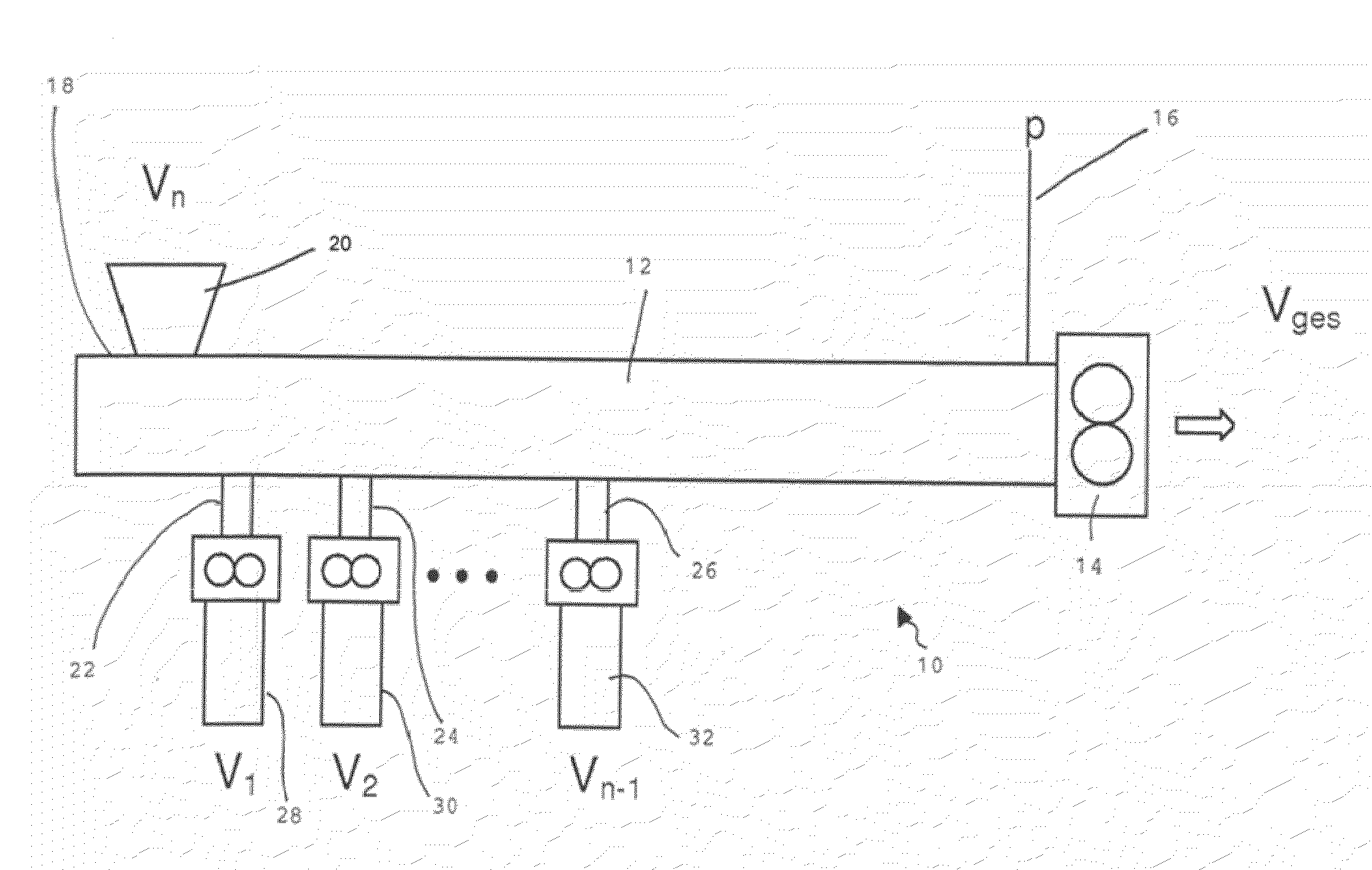

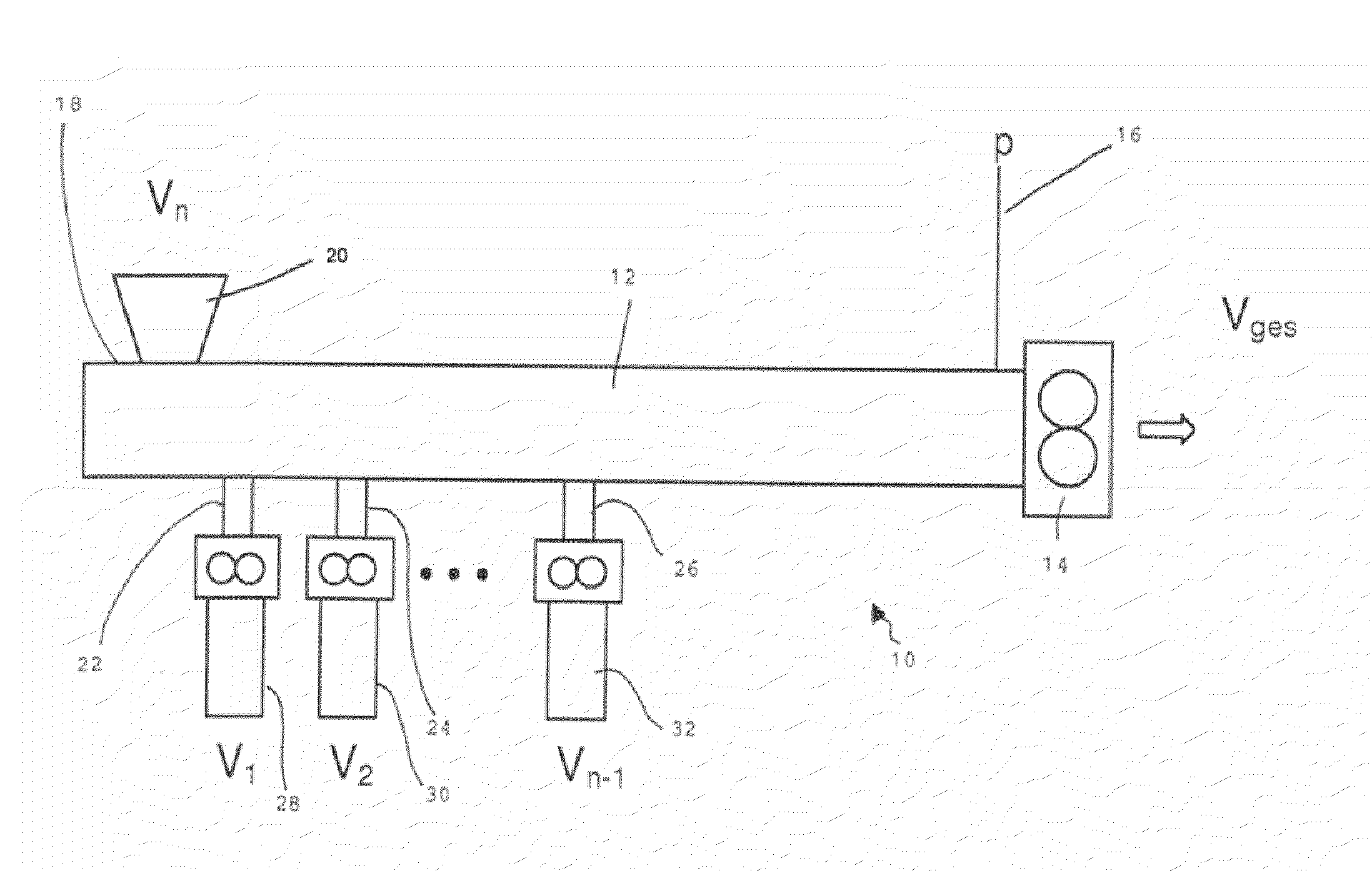

Mixing Machine For Components

InactiveUS20090080282A1Good mixtureEasy to adjustDough mixing/kneading machinesThermoplastic elastomerEngineering

An extrusion conveying apparatus, including an extruder that operates as a mixing device and is laterally supplied with components that are to be mixed, in particular components of a rubber mixture or thermoplastic elastomer. A volumetrically operating conveyor, in particular a gear pump, is connected to the output side of the extruder. A rotational speed or feed rate of the extruder is adjustable independently of the feed rate and volume flow of the conveyor. n−1 volumetric subsidiary conveyors are provided for passage of components therethrough where there are n components of a mixture. In particular component n is supplied in an undosed manner. A rotational speed or feed rate of the subsidiary conveyors is adjustable independently of the feed rate of the volumetrically operating conveyor.

Owner:VMI AZ EXTRUSION

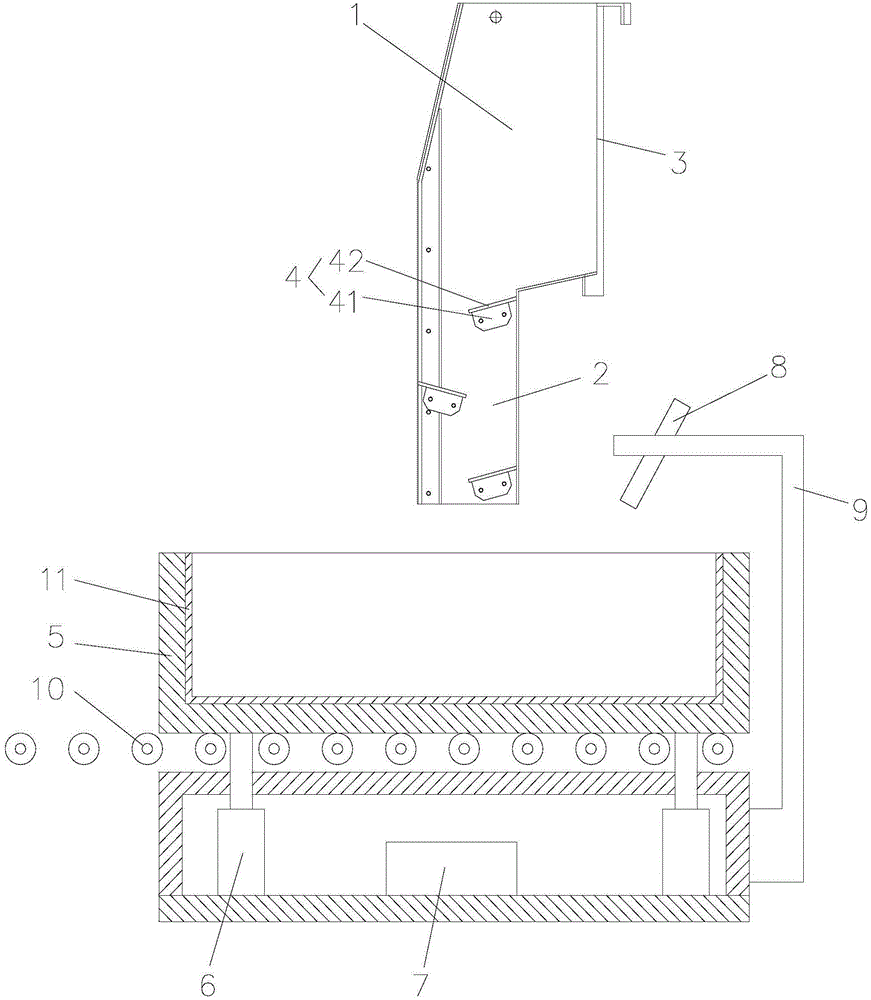

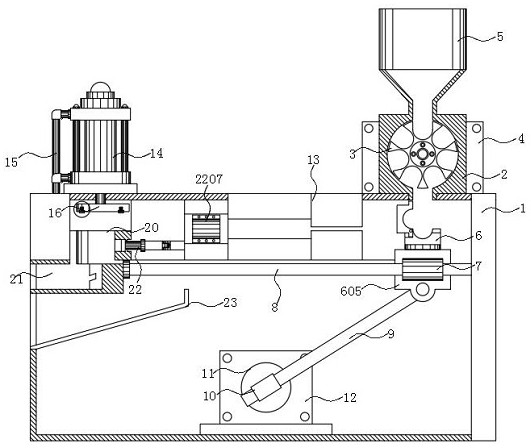

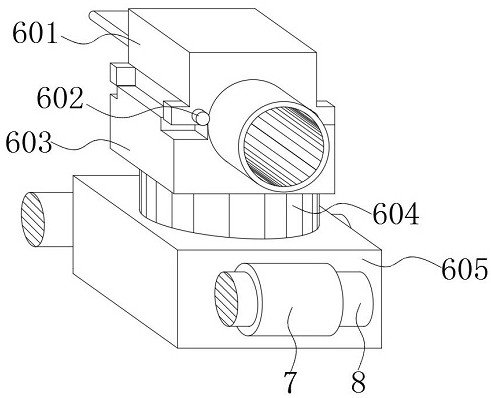

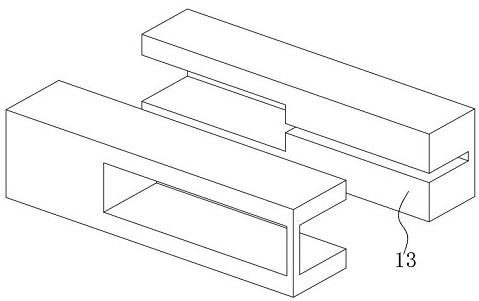

Automatic steel ball buffering and receiving device

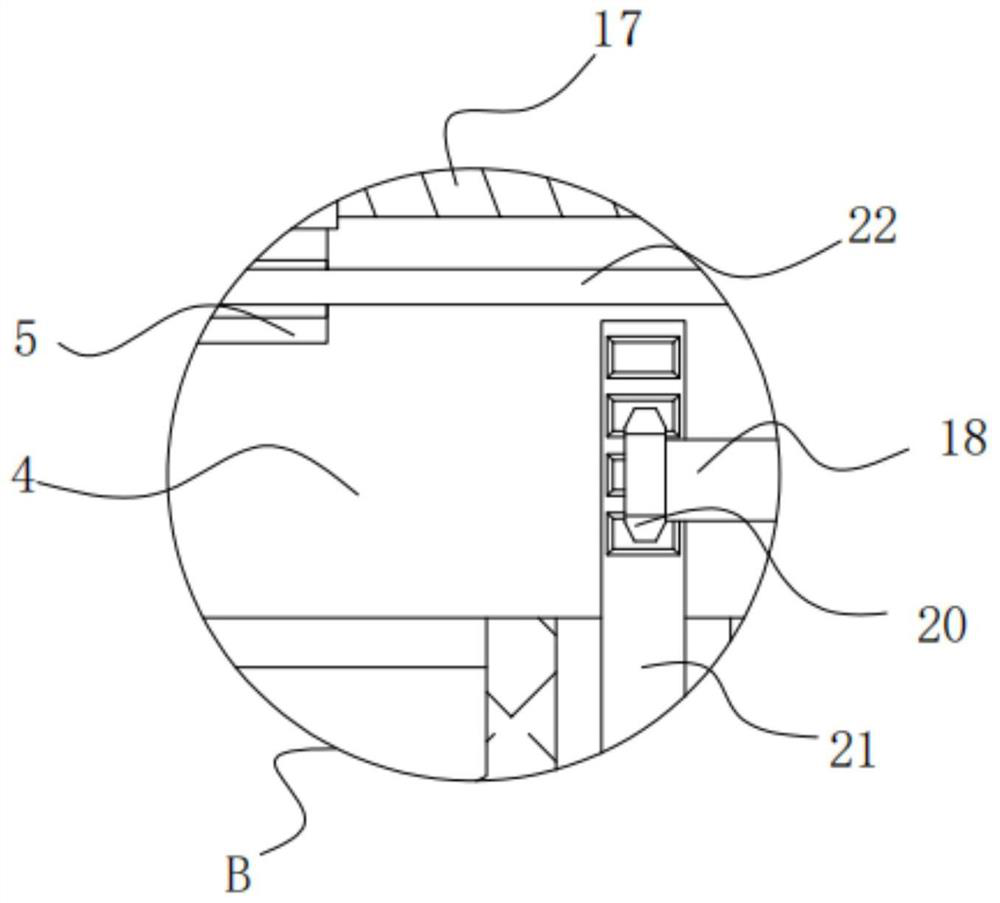

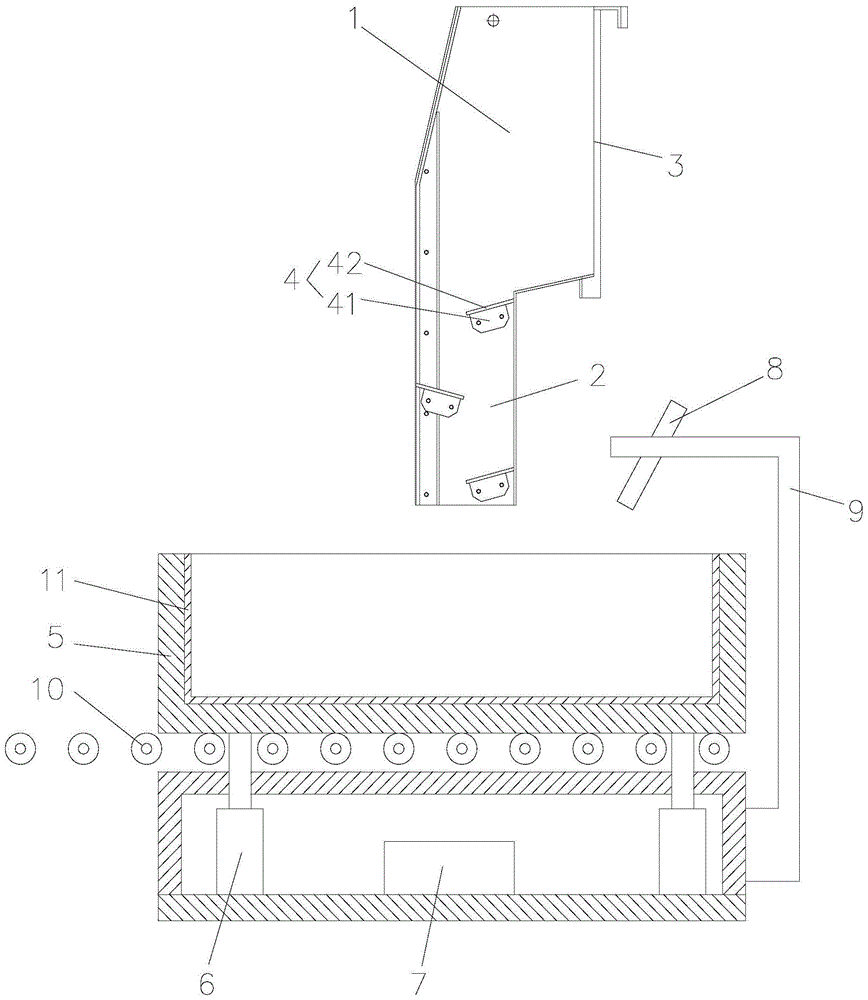

The invention discloses an automatic steel ball buffering and receiving device which comprises a buffering blanking device and a lifting receiver. The buffering blanking device comprises a feeding pipe and a blanking pipe. The blanking pipe is internally provided with inclined buffering plates for enabling steel balls to fall in a zigzag track mode and arranged in a staggered mode. The lifting receiver comprises a ball receiving frame, an air cylinder, a controller and a position sensor. Due to the fact that the steel balls are blocked by the inclined buffering plates in the blanking pipe, the steel balls are made to fall in the zigzag track mode, and the falling speed of the steel balls is greatly reduced, so that the problem the steel balls are collided and damaged in the blanking process can be avoided; the position sensor is used to detect the height position of the steel balls in the ball receiving frame, when the position sensor detects that the steel ball position is lower than the set position, the ball receiving frame is lifted to shorten the steel ball falling height, so that the problem that the steel balls are collided and damaged can be avoided; when the position sensor detects that the steel ball position is higher than the set position, the ball receiving frame is lowered, the steel ball falling height is increased, and the problem that a steel ball discharging opening is blocked can be avoided.

Owner:TSUBAKI HOOVER (CHONGQING) CORP LTD

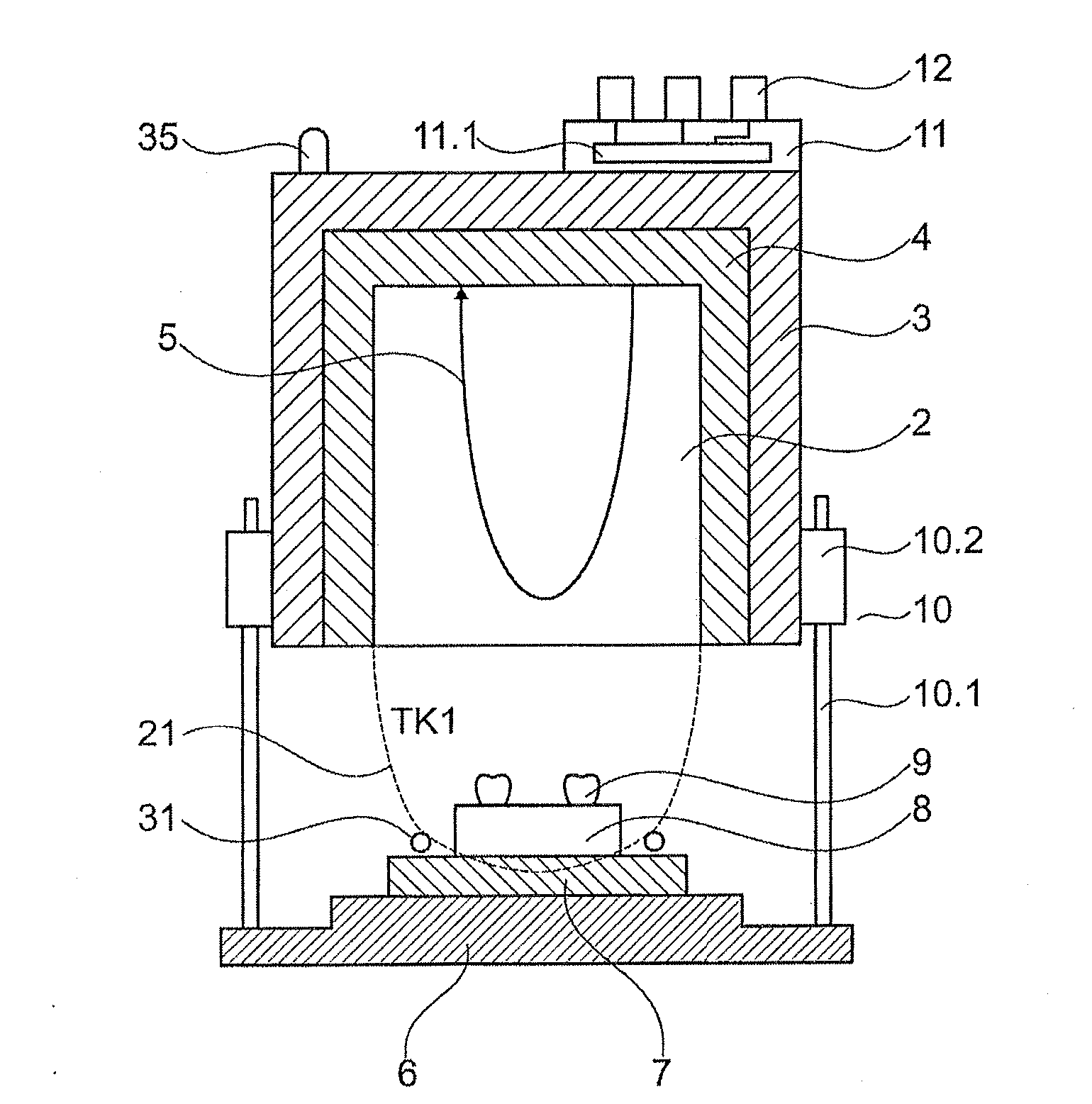

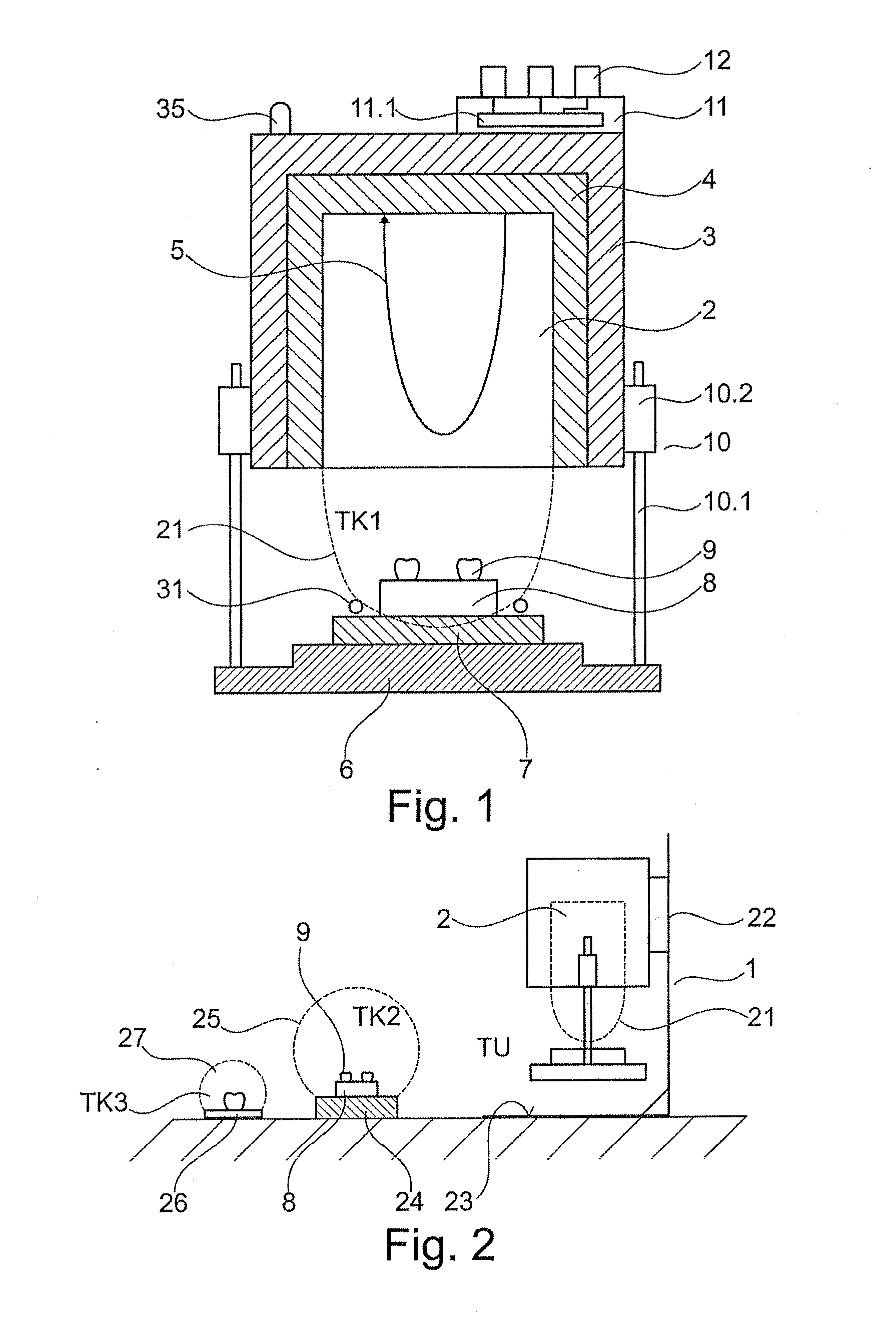

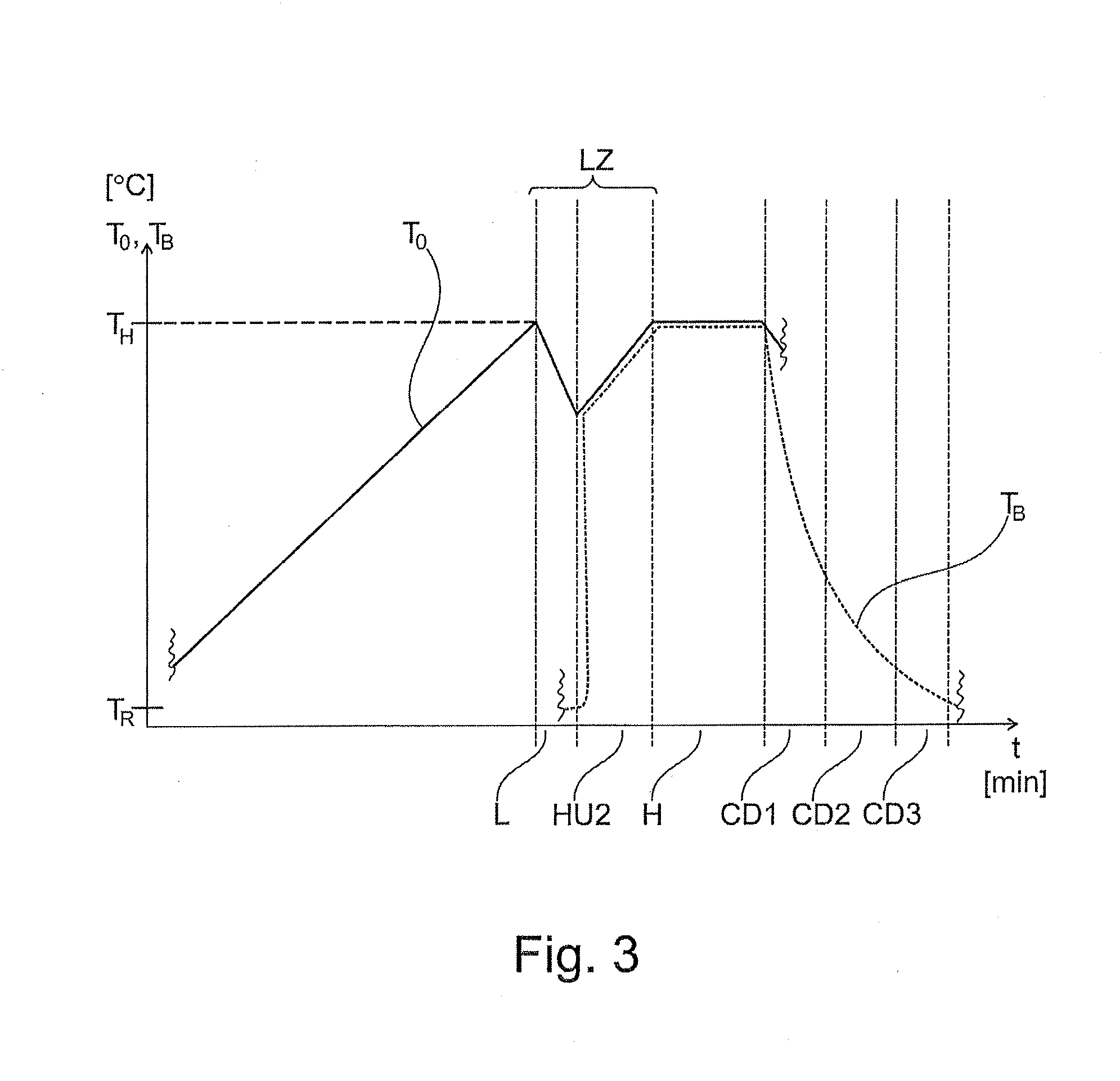

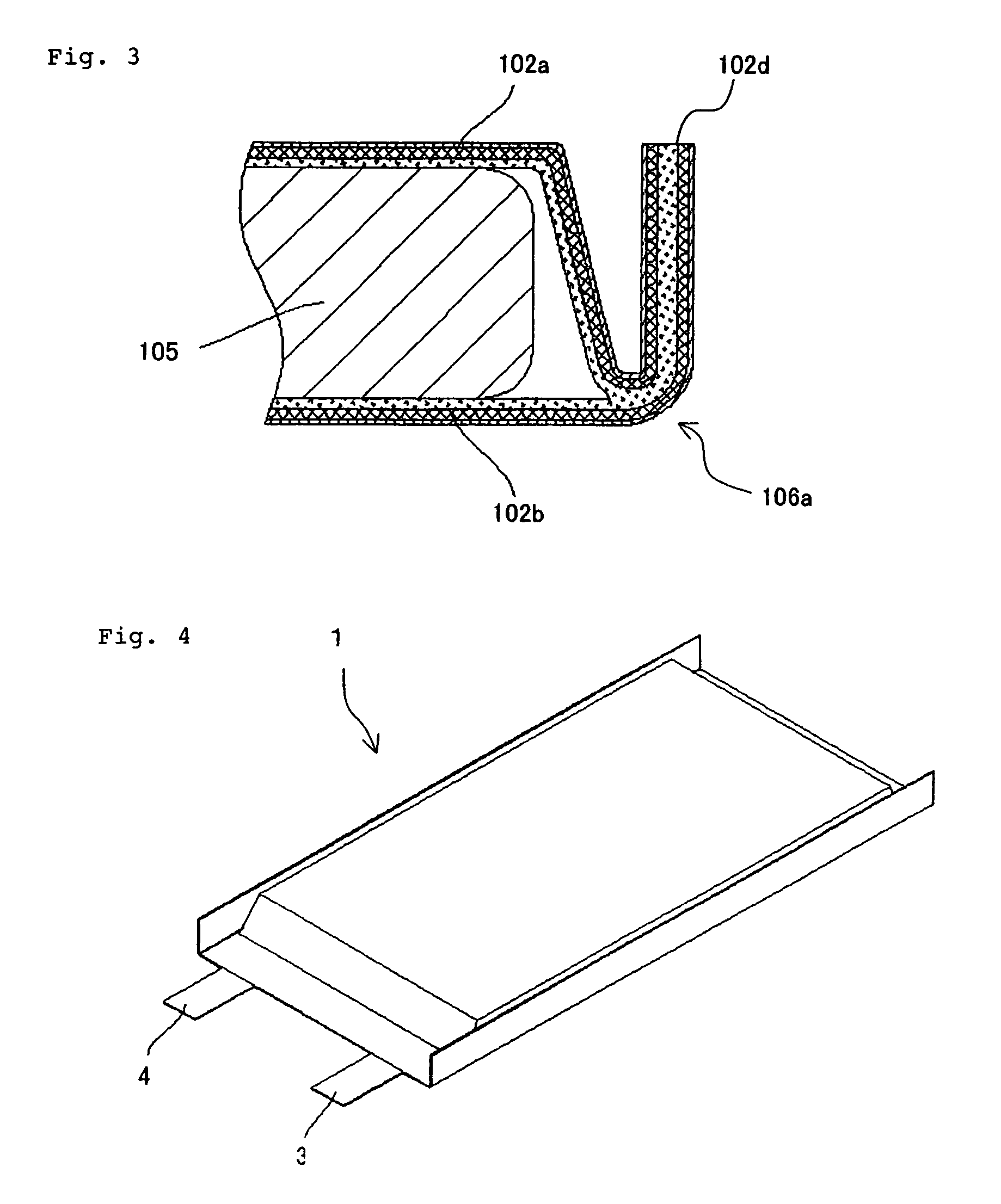

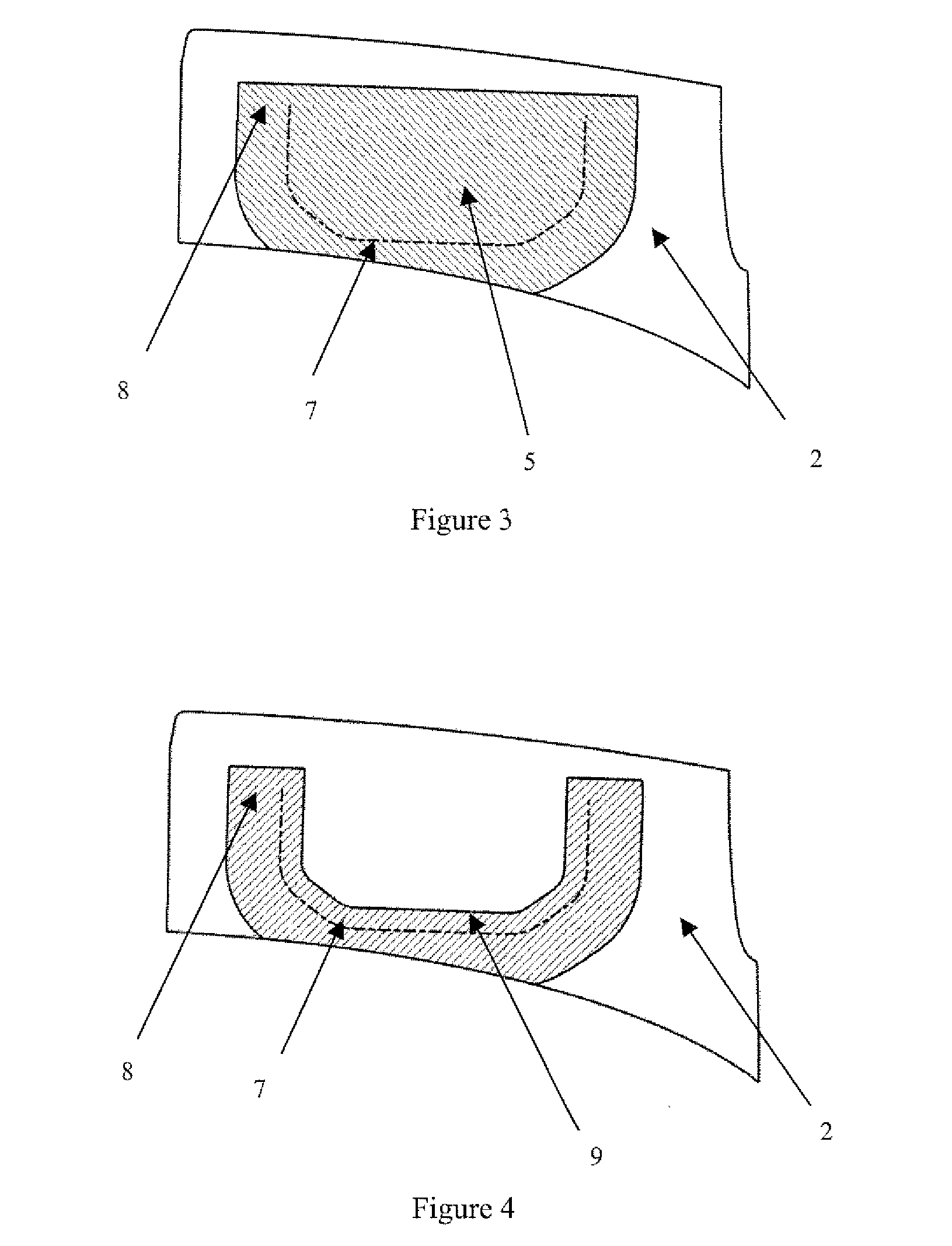

Sintering furnace for components consisting of a sintering material, in particular for dental components, and a method for sintering such components

ActiveUS20150247672A1Reduce processing timeReduction of process throughput timeCrucible furnacesControl devices for furnacesMetallurgyComputer program

The invention relates to a sintering furnace for components consisting of sintering material, especially dental components and in particular components consisting of ceramic, and a method for sintering such components. The sintering furnace 1 comprises a heatable furnace chamber 2 for the component 9 to be sintered, the furnace chamber 2 having a wall section 6 to be opened for inserting the component 9 to be sintered into the furnace chamber 2. Drive means 10 are provided for mechanized opening and closing of the wall section 6, and a control 11 is provided for the drive means 10 that has an actuation element 12 for the drive means 10. Furthermore, a heating device 5 for the furnace chamber 2 is provided, and the control 11 causes the furnace chamber 2 to be heated. Actuating the control element 12 triggers the loading sequence of the control 11, and the drive means 10 are automatically actuated by the control 11 corresponding to the loading sequence. An additional subject is a method for operating the sintering furnace, as well as a computer program therefor.

Owner:SIRONA DENTAL SYSTEMS

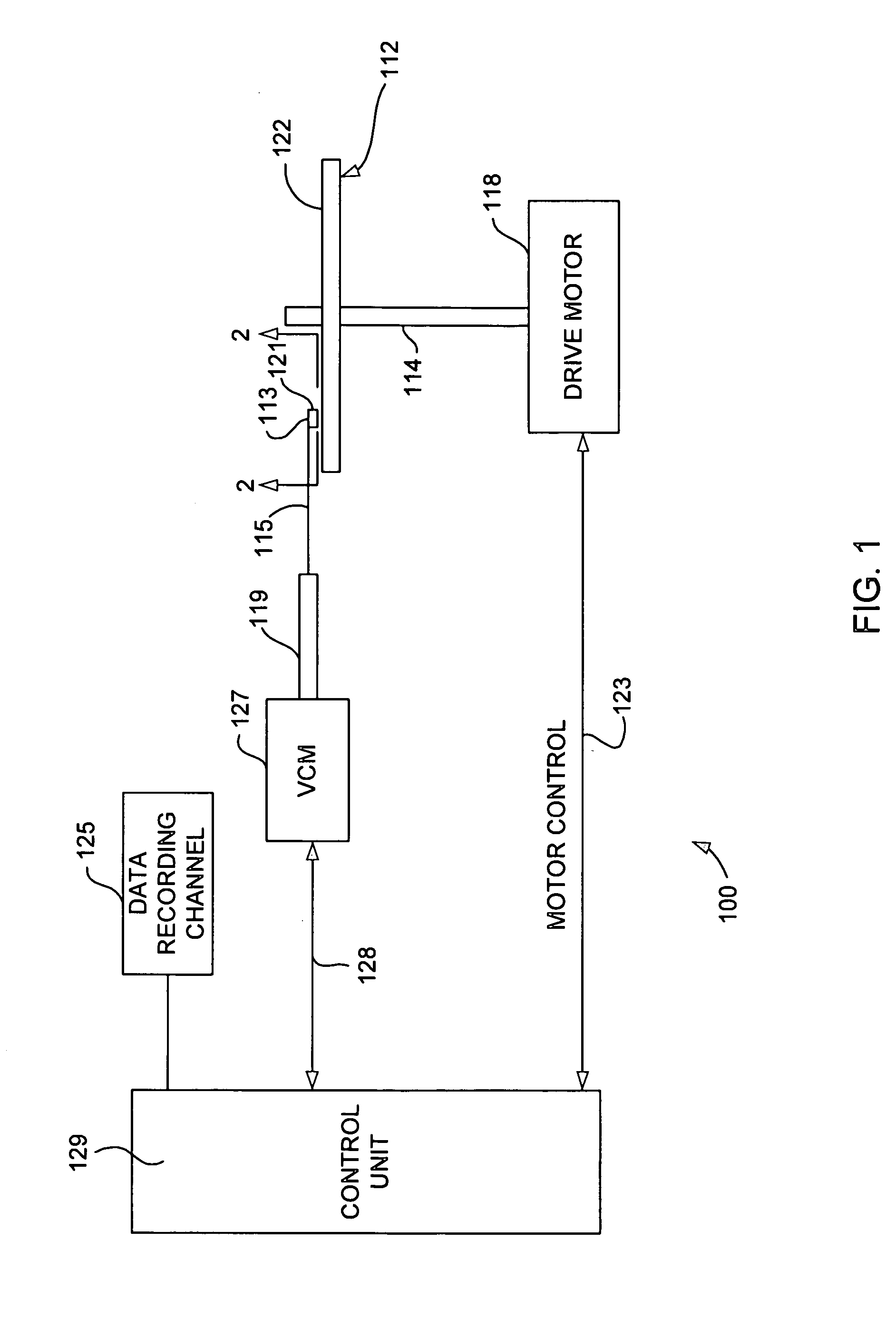

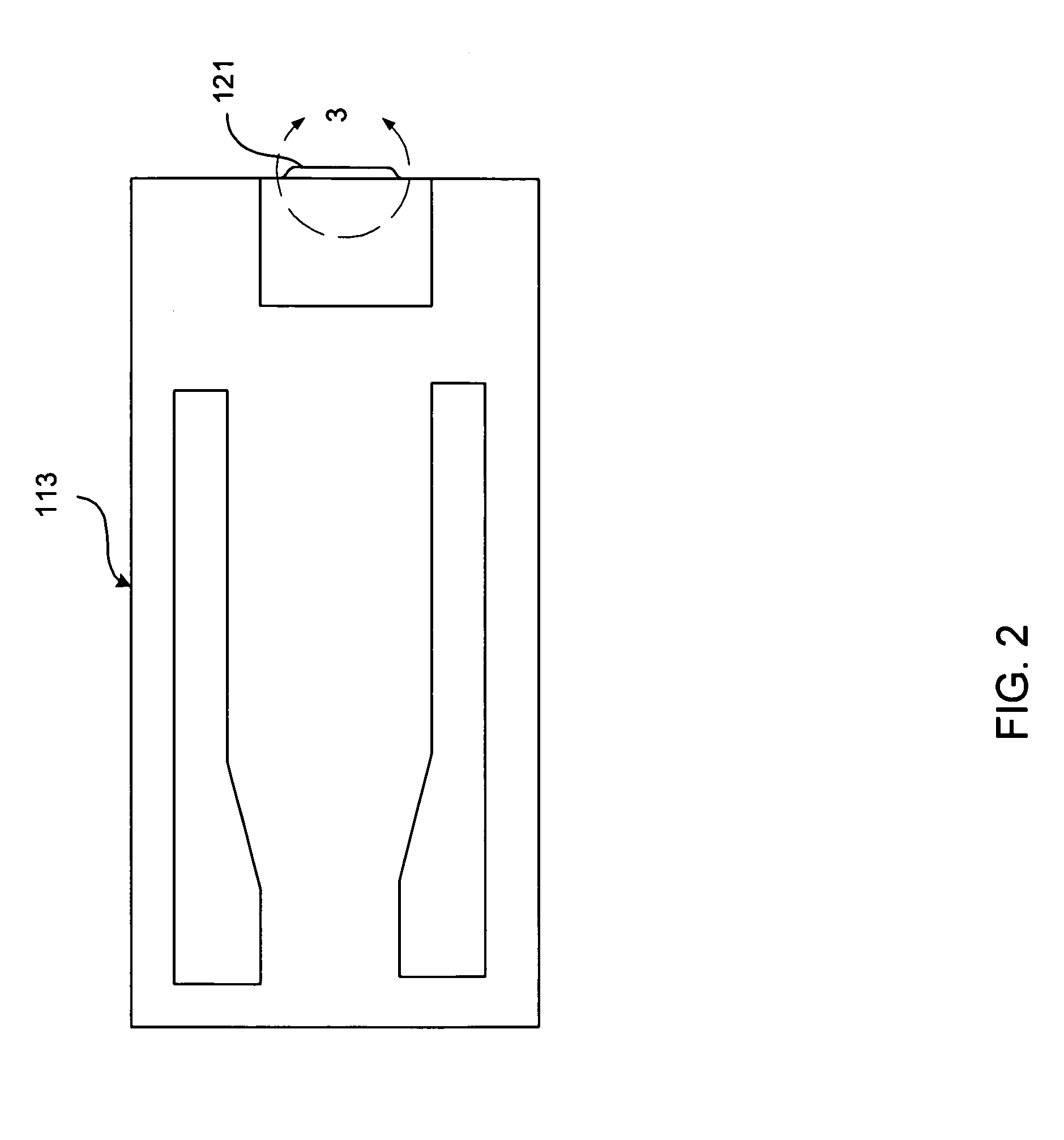

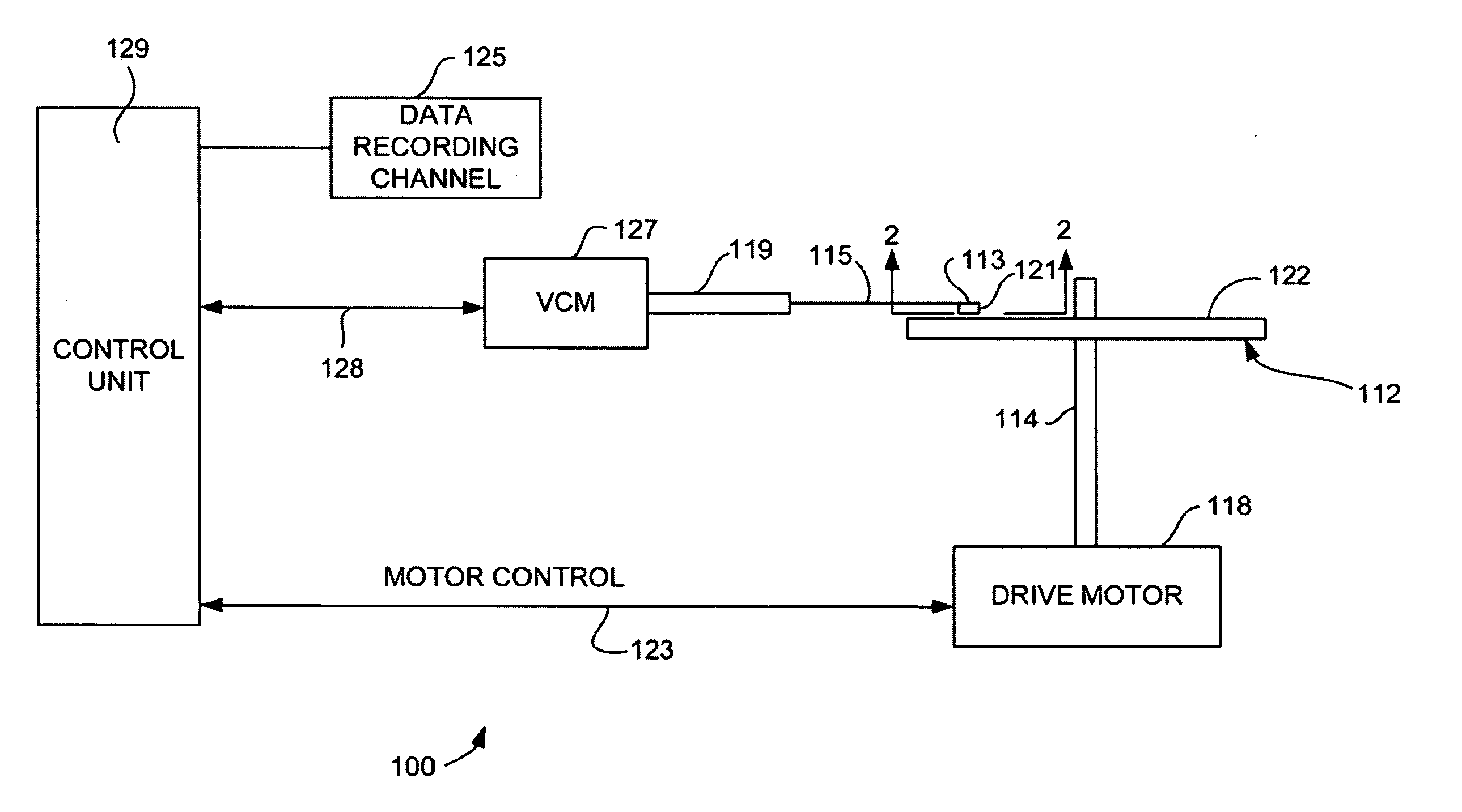

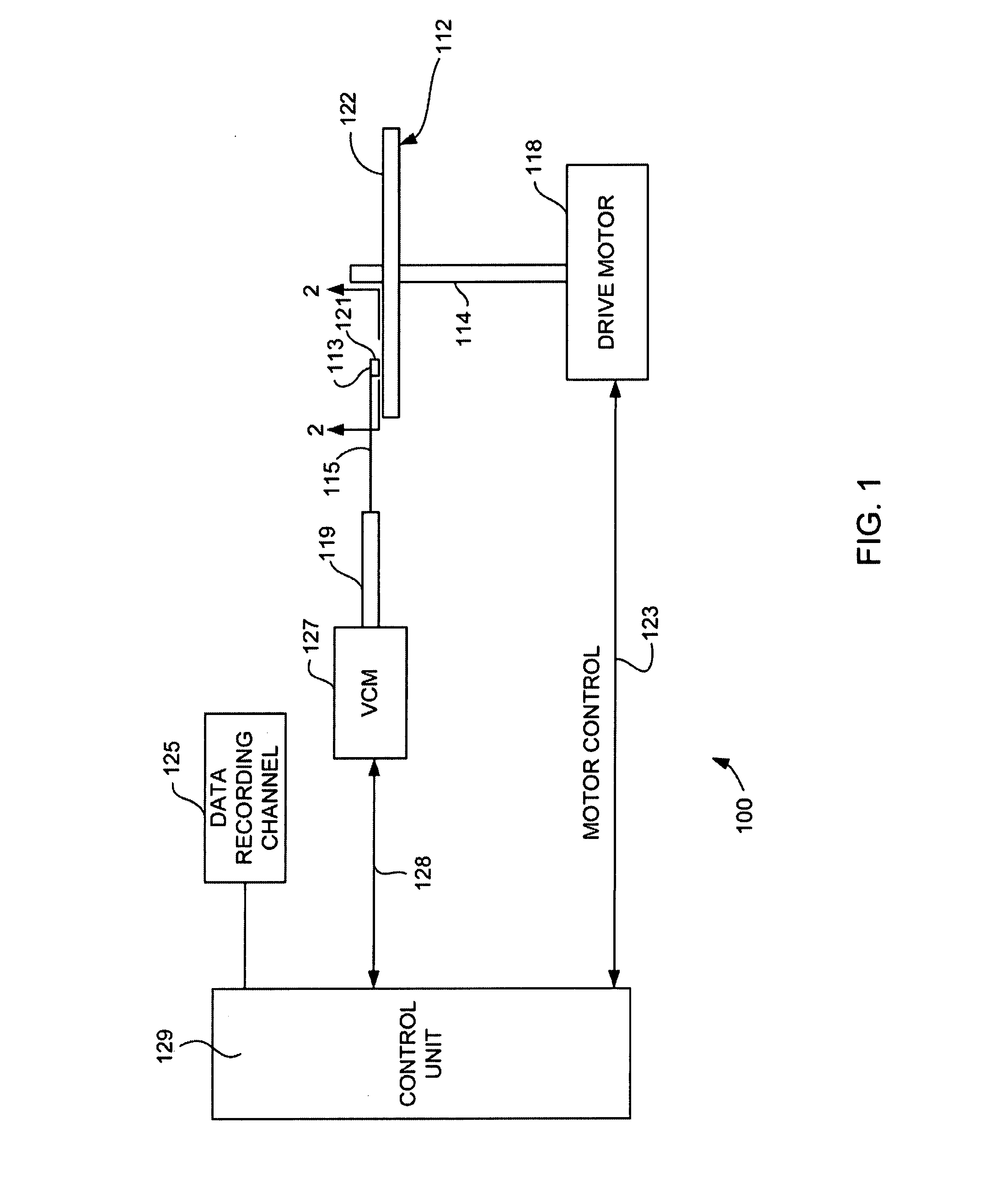

Topographically defined thin film CPP read head fabrication

InactiveUS20050227184A1Avoids sensor material damageHigh graphics resolutionNanoinformaticsHeads using thin filmsEngineeringElectrical and Electronics engineering

A method of constructing a small trackwidth magnetorsesistive sensor by defining a trench between first and second hard bias layers and depositing the sensor into the trench.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

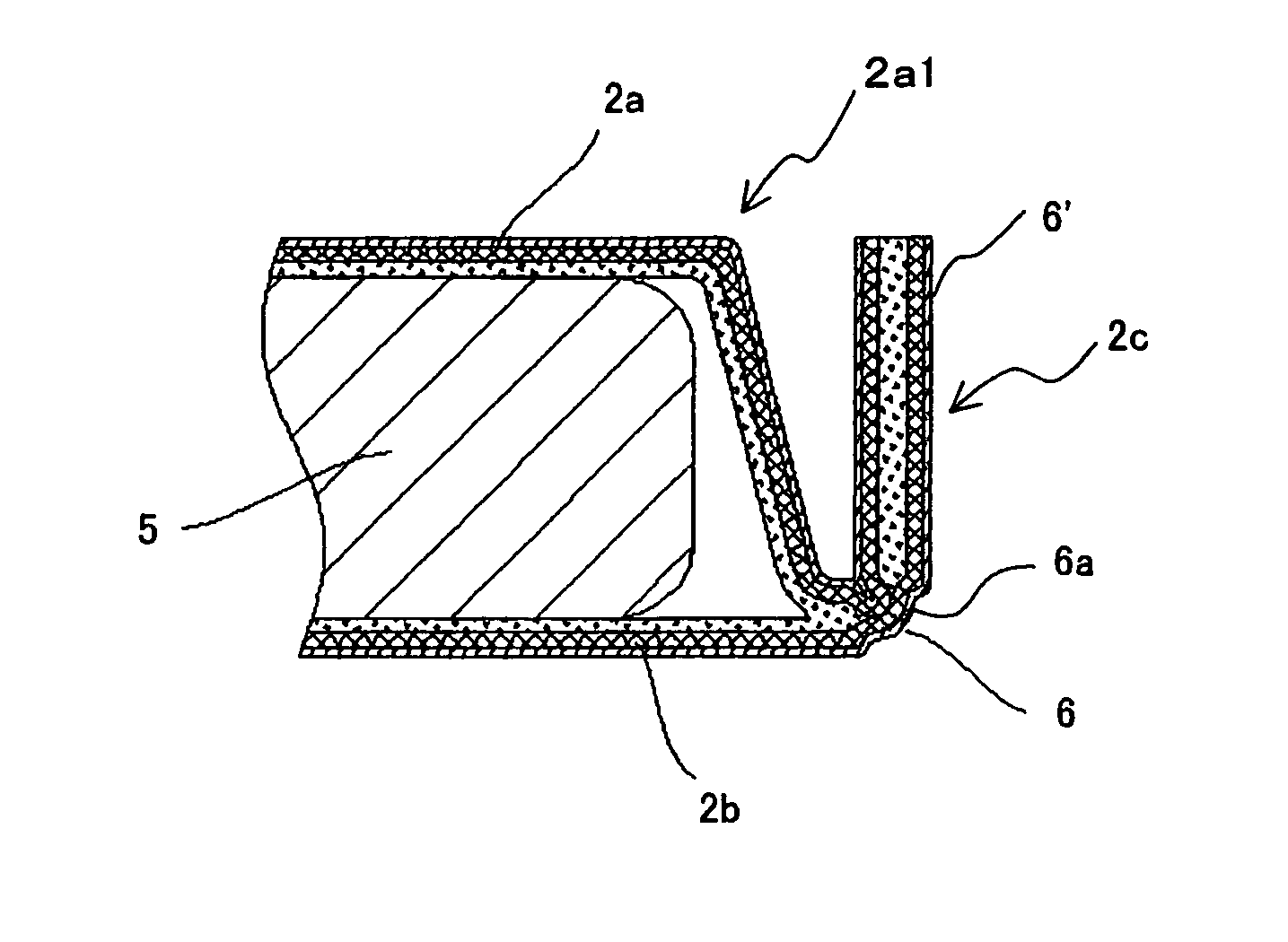

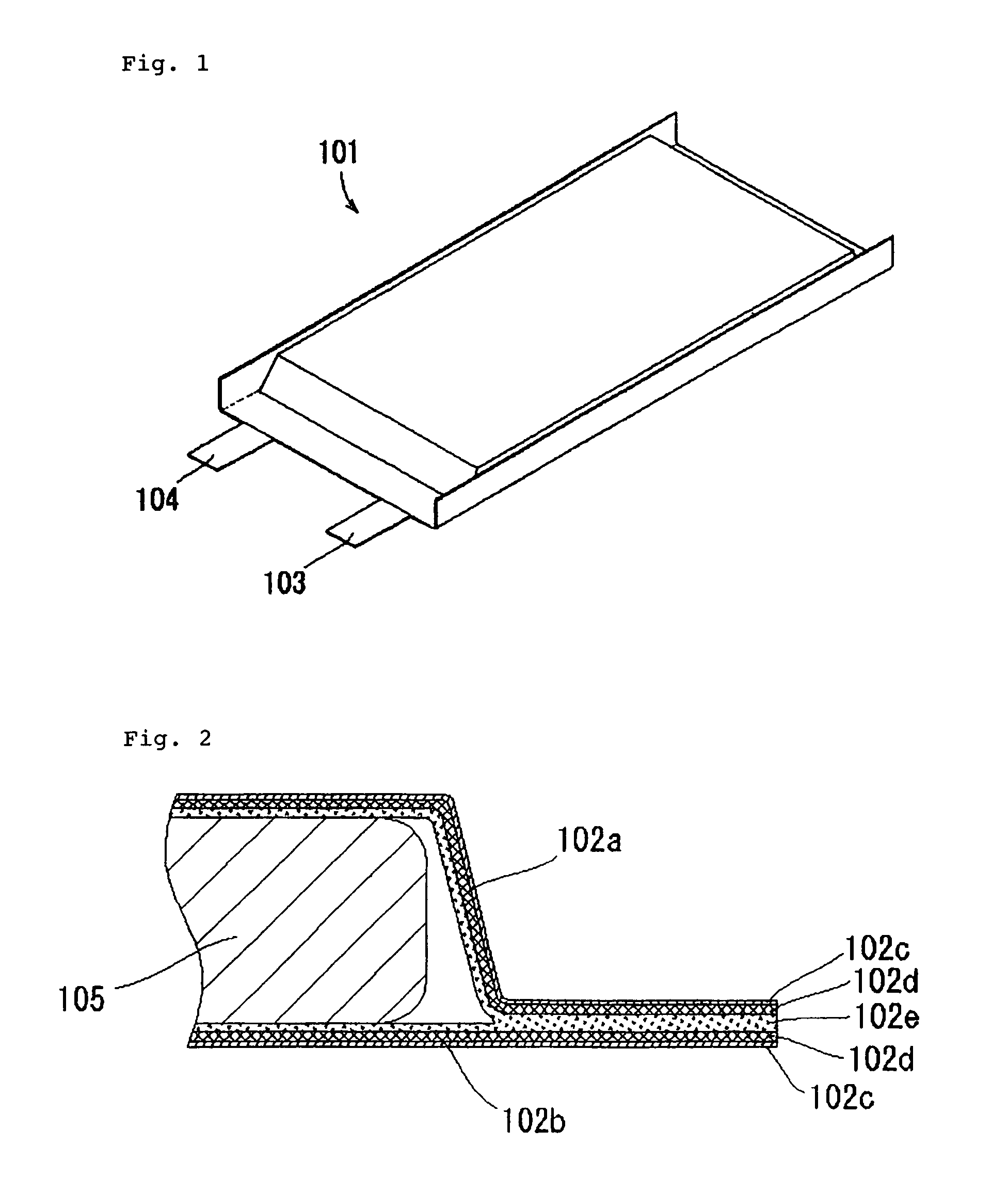

Film-clad battery and method of producing film-clad battery

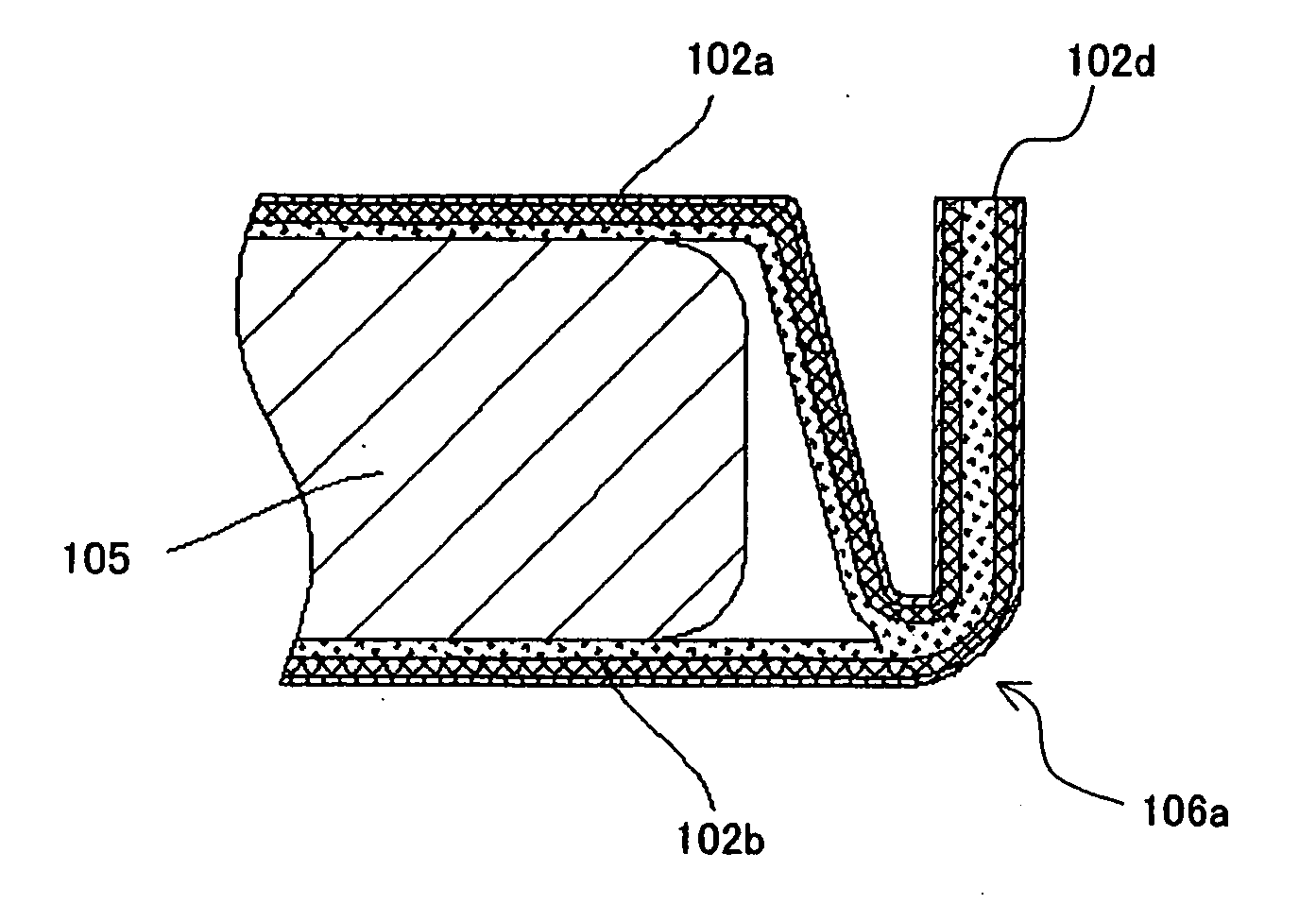

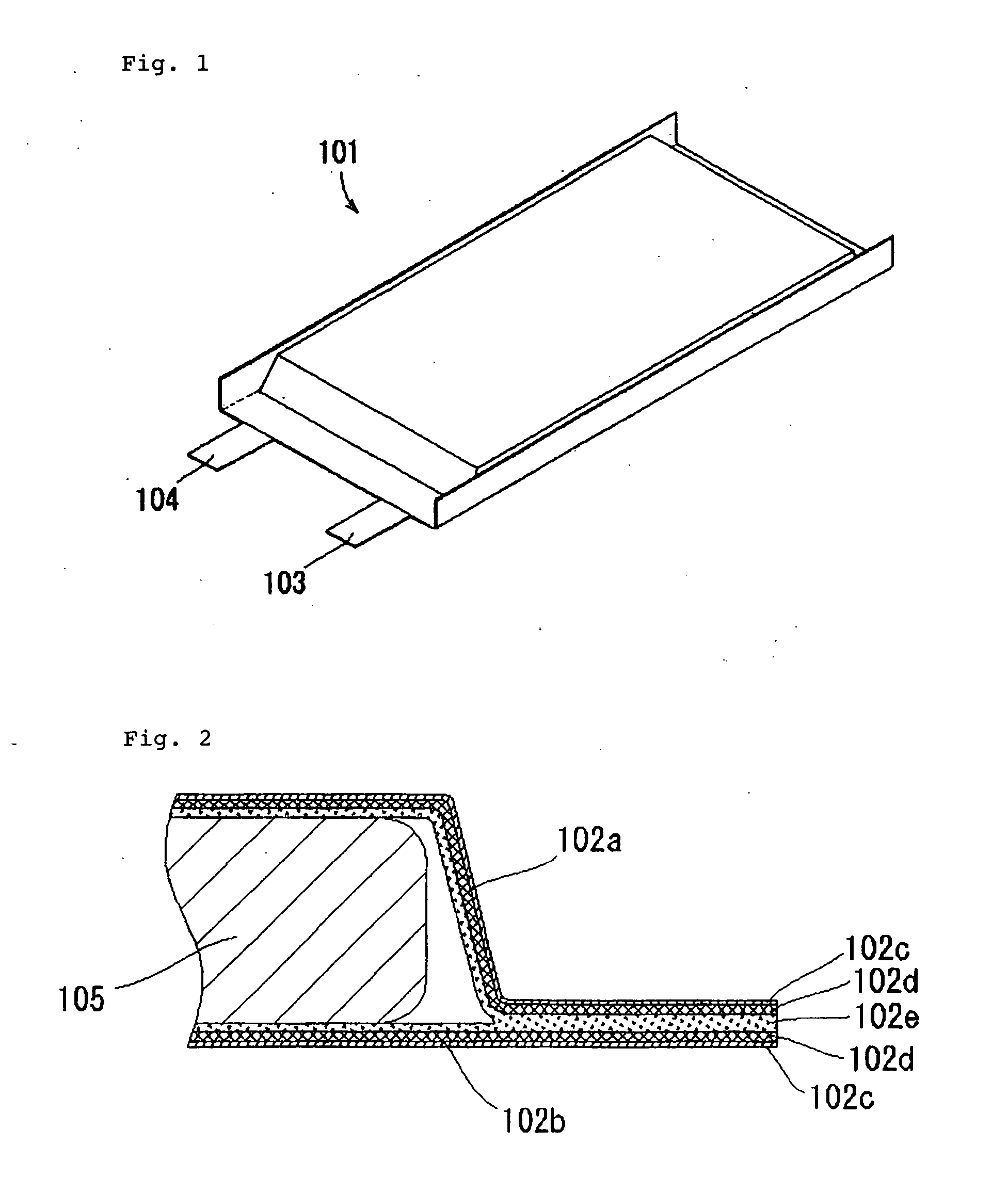

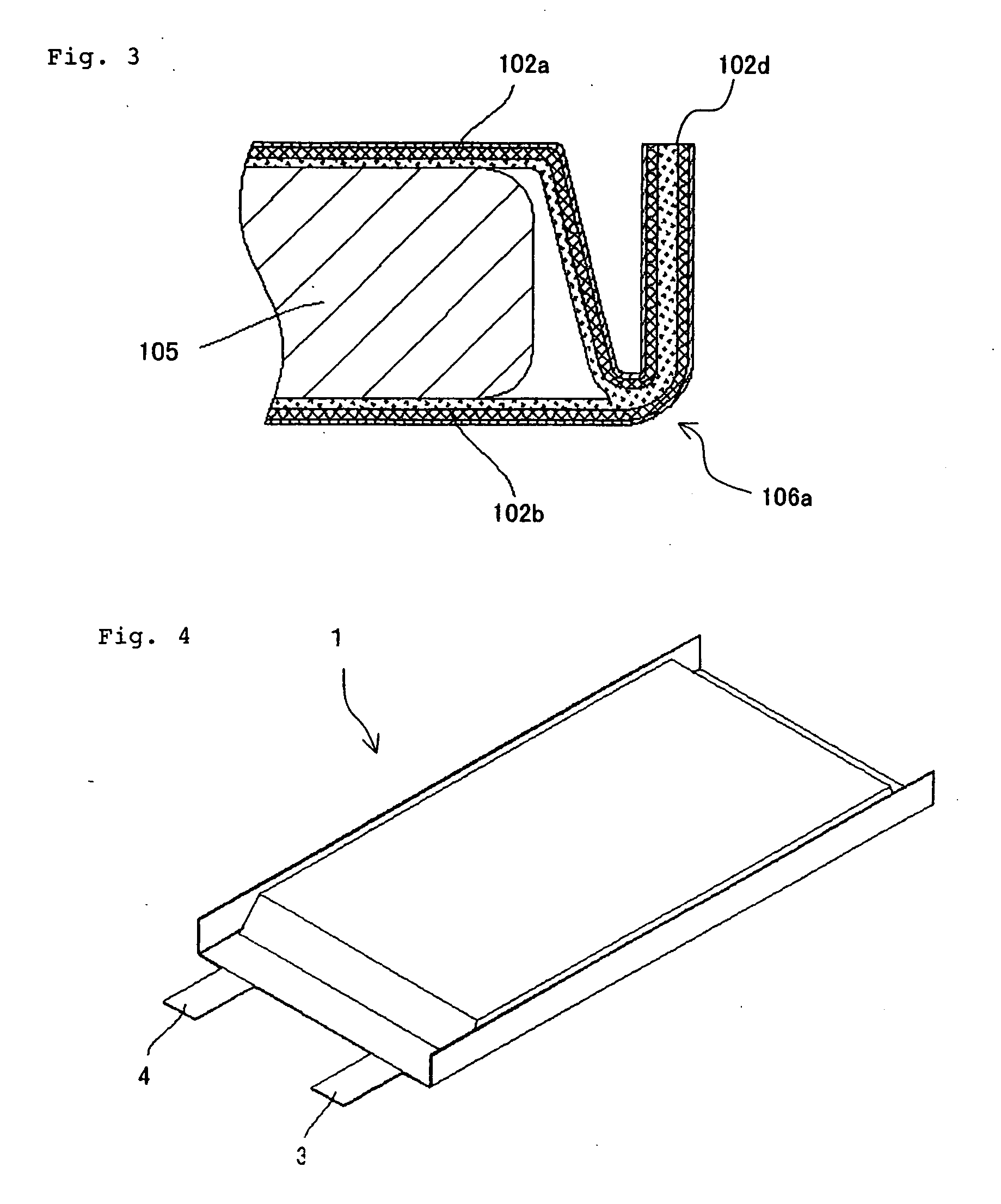

ActiveUS20070009795A1Avoid damageImprove performanceFinal product manufactureElectrode carriers/collectorsEngineering

Owner:NEC CORP

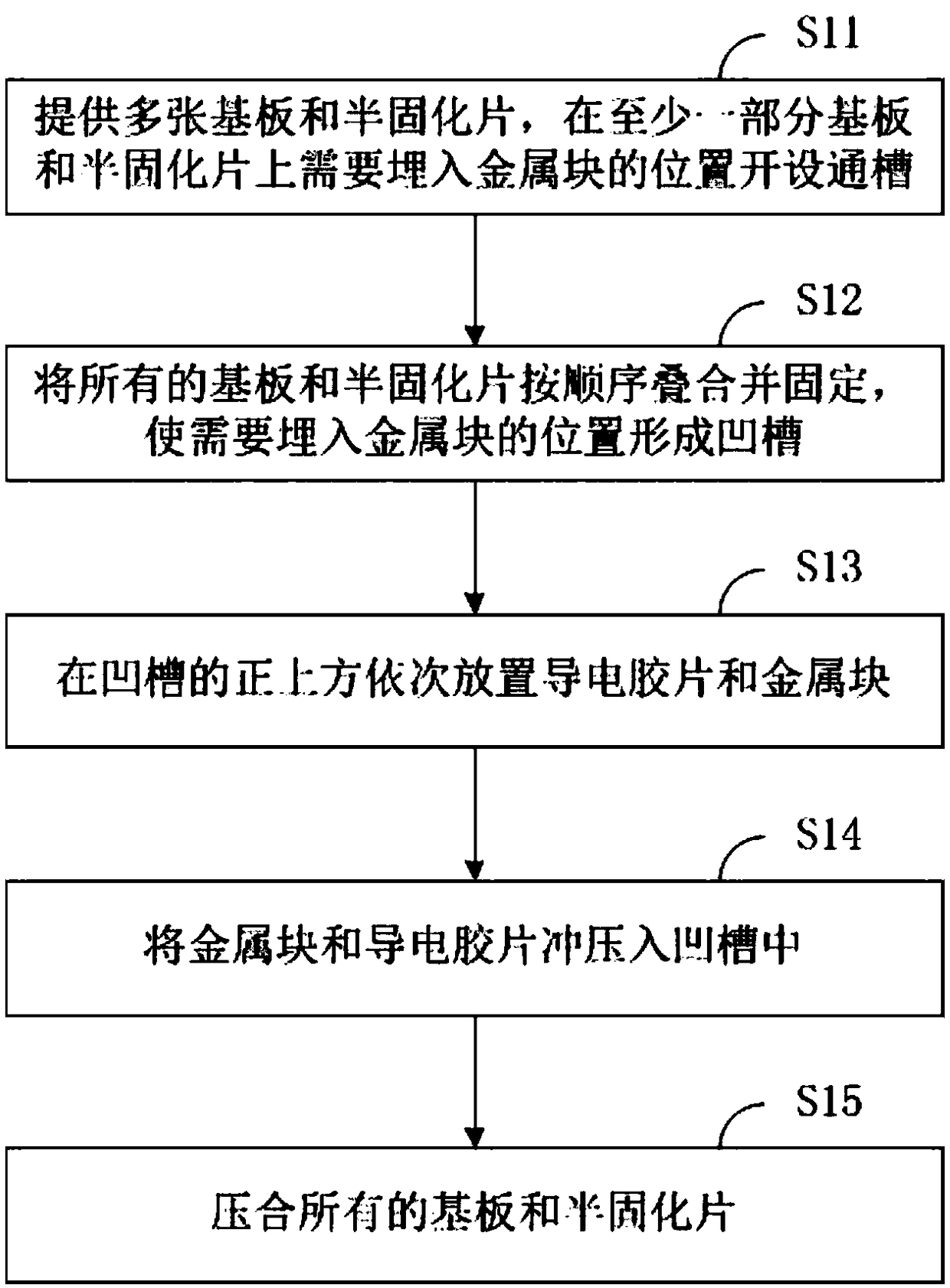

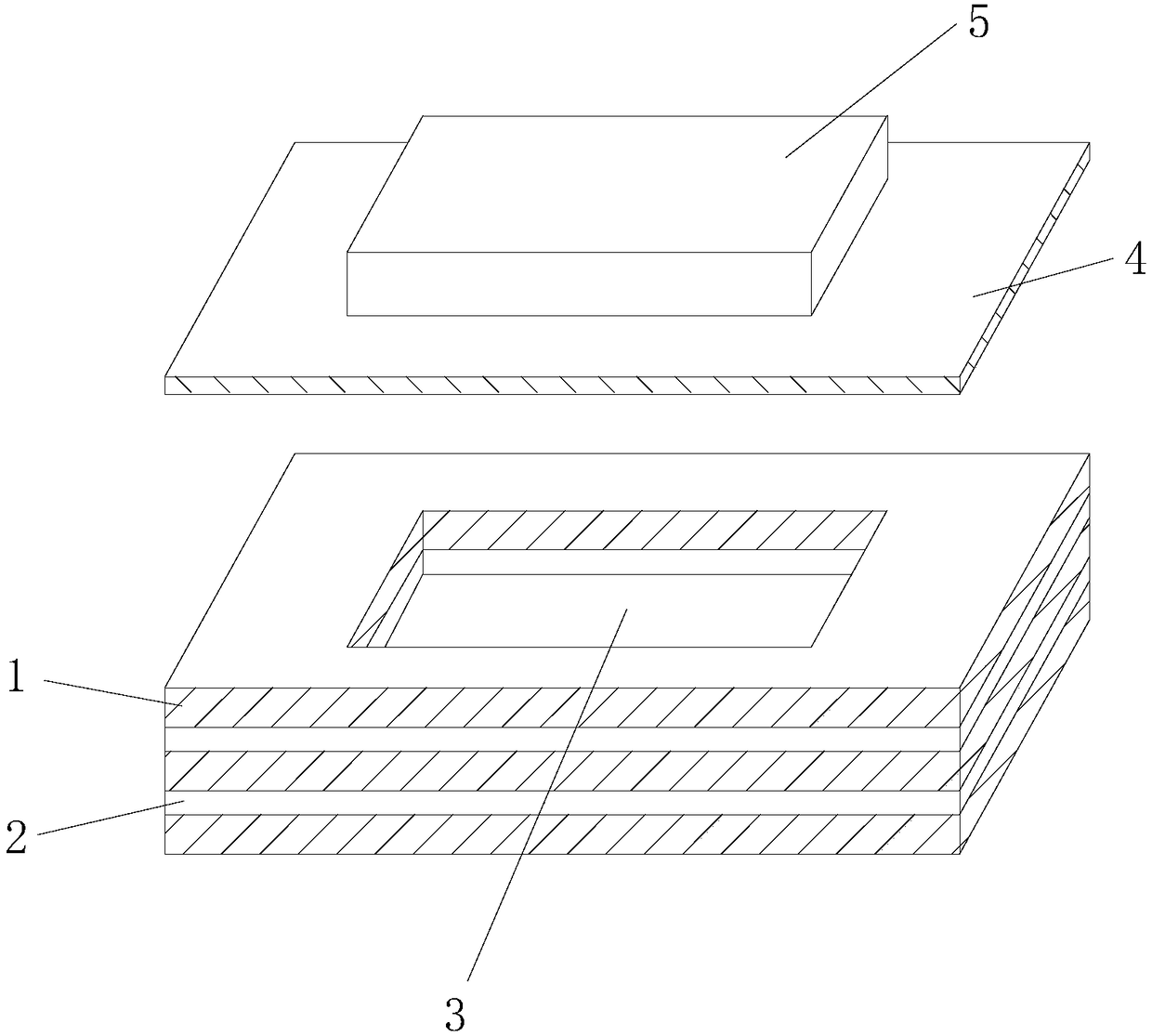

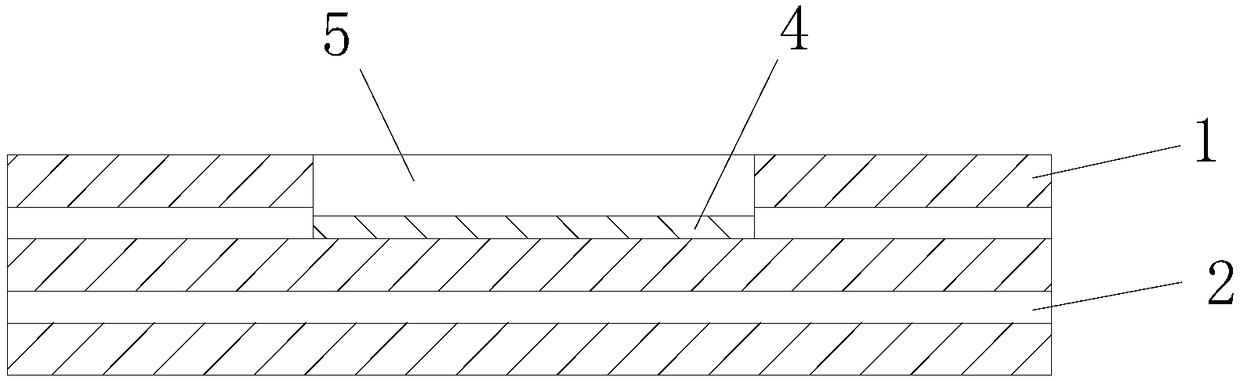

PCB and manufacturing method thereof

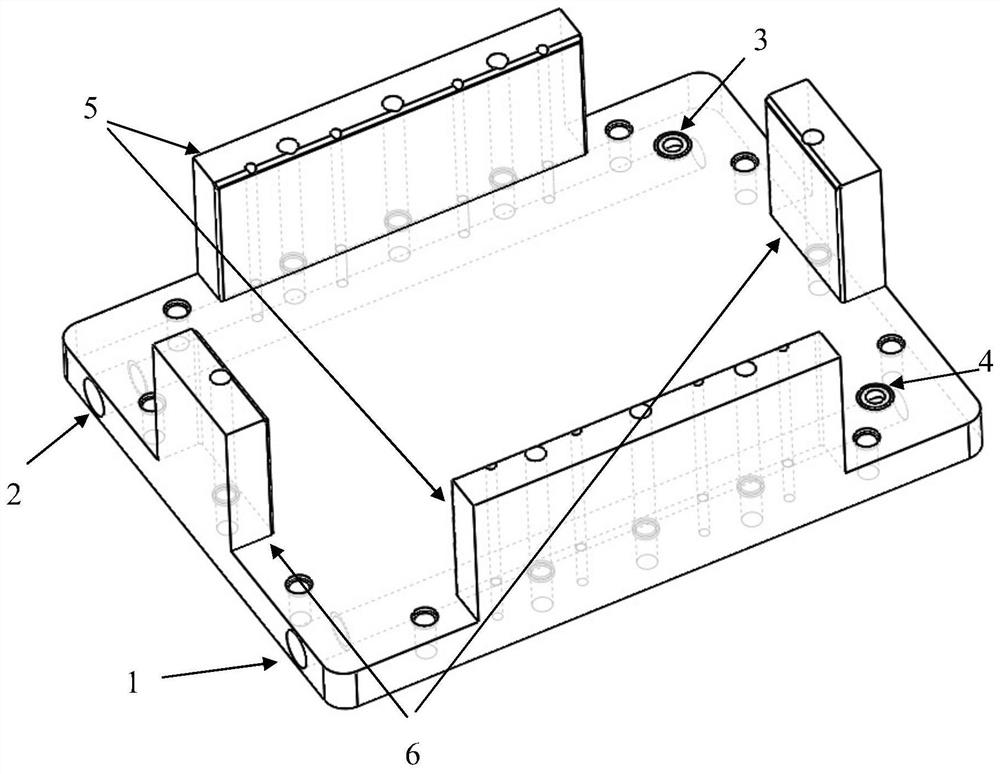

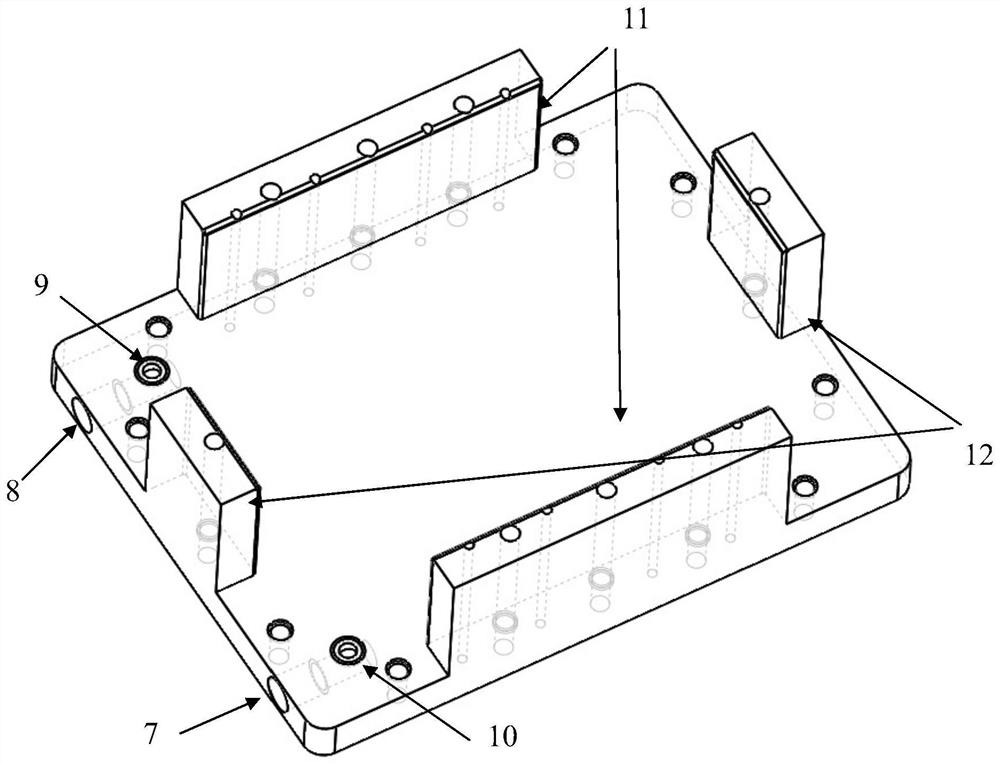

InactiveCN108419382AAvoid misalignmentAvoid material damagePrinted circuit aspectsMultilayer circuit manufactureManufacturing technologyHeat conducting

The invention discloses a PCB and a manufacturing method thereof, and relates to PCB manufacturing technologies. The manufacturing method of the PCB comprises that substrates and prepregs are provided, slots are formed in positions, into which metal blocks are embedded, of at least part of the substrates and the prepregs; all the substrates and prepregs are stacked and fixed sequentially, and grooves are formed in the positions into which metal blocks are embedded; a conducting resin sheet and a metal block are disposed above the groove; the metal block and the conducting resin sheet are stamped into the groove; and all the substrates and prepregs are laminated. A conductive and heat conducting material and the metal block can be placed in at the same time, it is not required to mill the conductive and heat conducting material into small units in advance, problems of offset, material damage and pollution due to taking the small units of the conductive and heat conducting material manually can be prevented, the production efficiency can be improved obviously, and the problem of low aligning degree can be solved.

Owner:DONGGUAN SHENGYI ELECTRONICS

Chip package and method for fabricating the same

ActiveUS8207615B2Improves yield and reliabilityMuch successSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineering

An embodiment of the invention provides a chip package, which includes a substrate having an upper surface and a lower surface, a chip disposed in or on the substrate, a pad disposed in or on the substrate and electrically connected to the chip, a hole extending from the lower surface toward the upper surface, exposing the pad, wherein a lower opening of the hole near the lower surface has a width that is shorter than that of an upper opening of the hole near the upper surface, an insulating layer located overlying a sidewall of the hole, and a conducting layer located overlying the insulating layer and electrically connected to the pad.

Owner:XINTEC INC

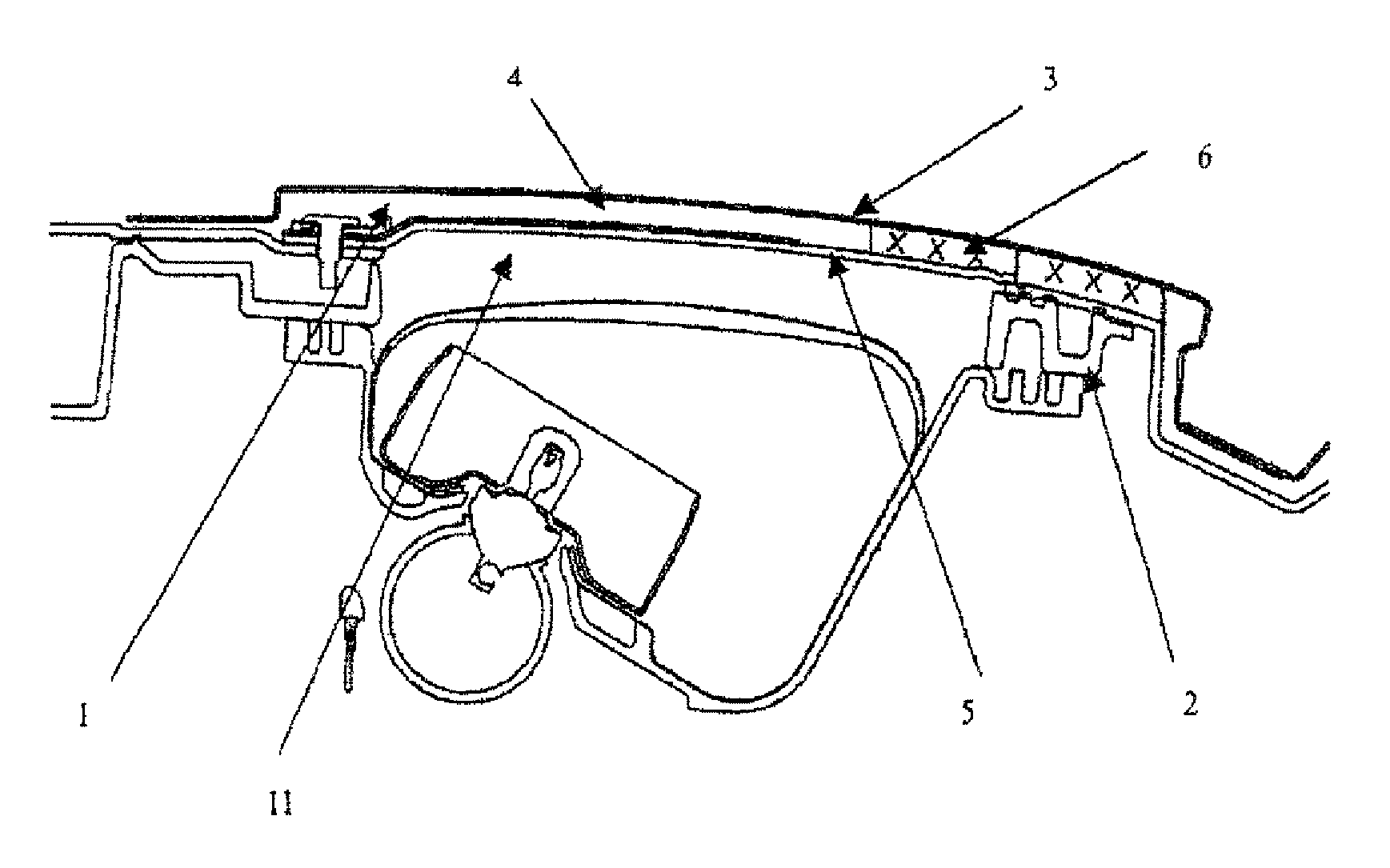

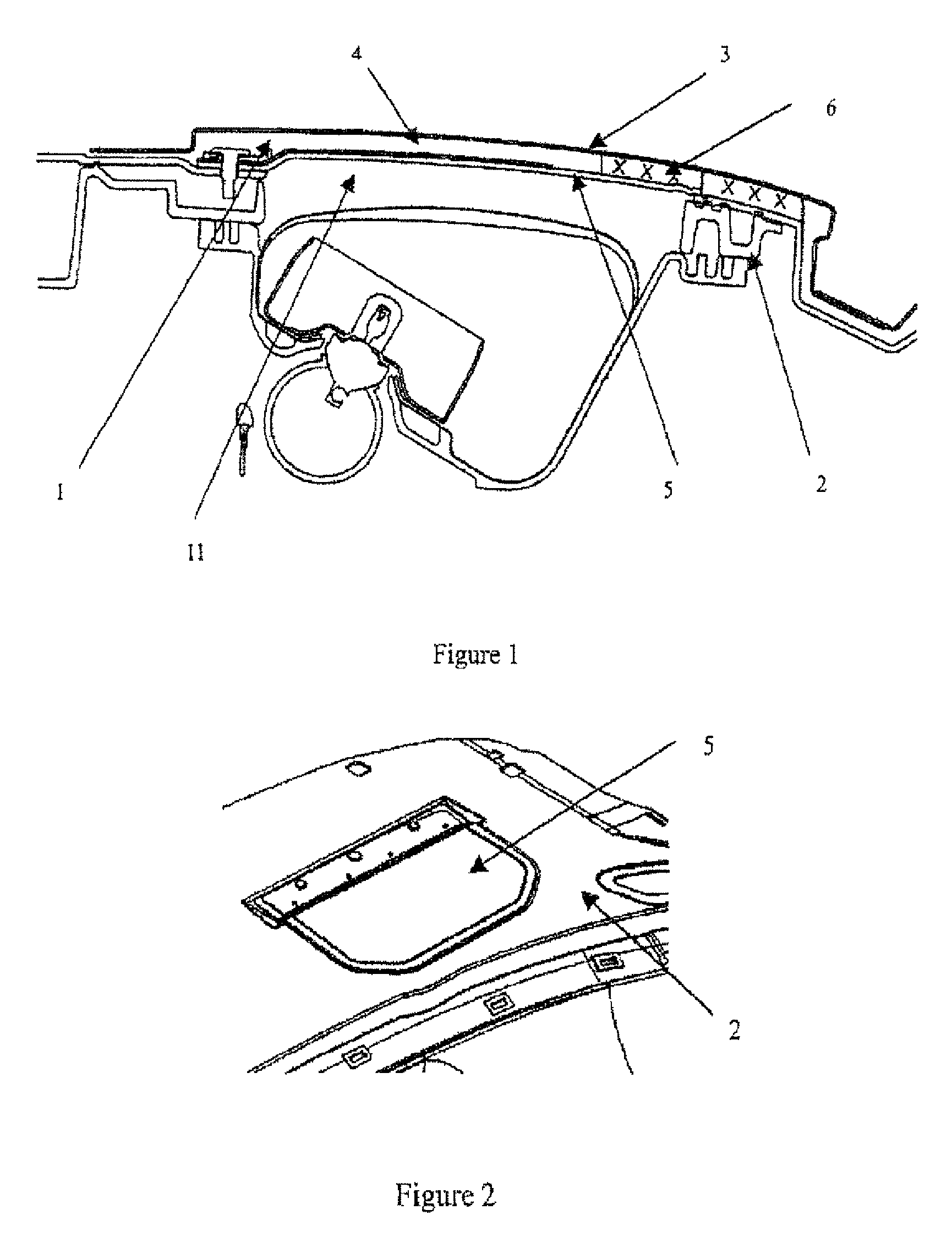

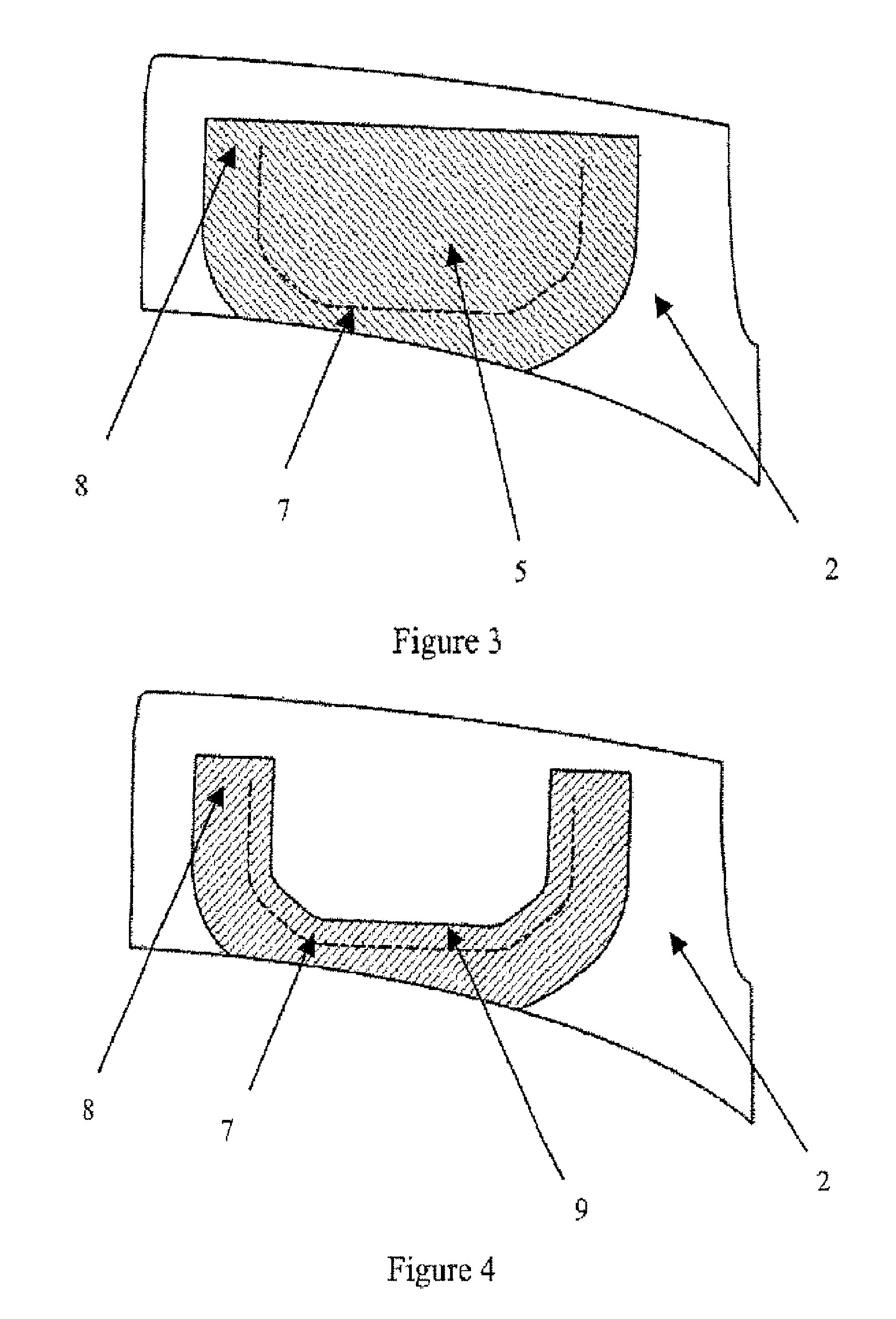

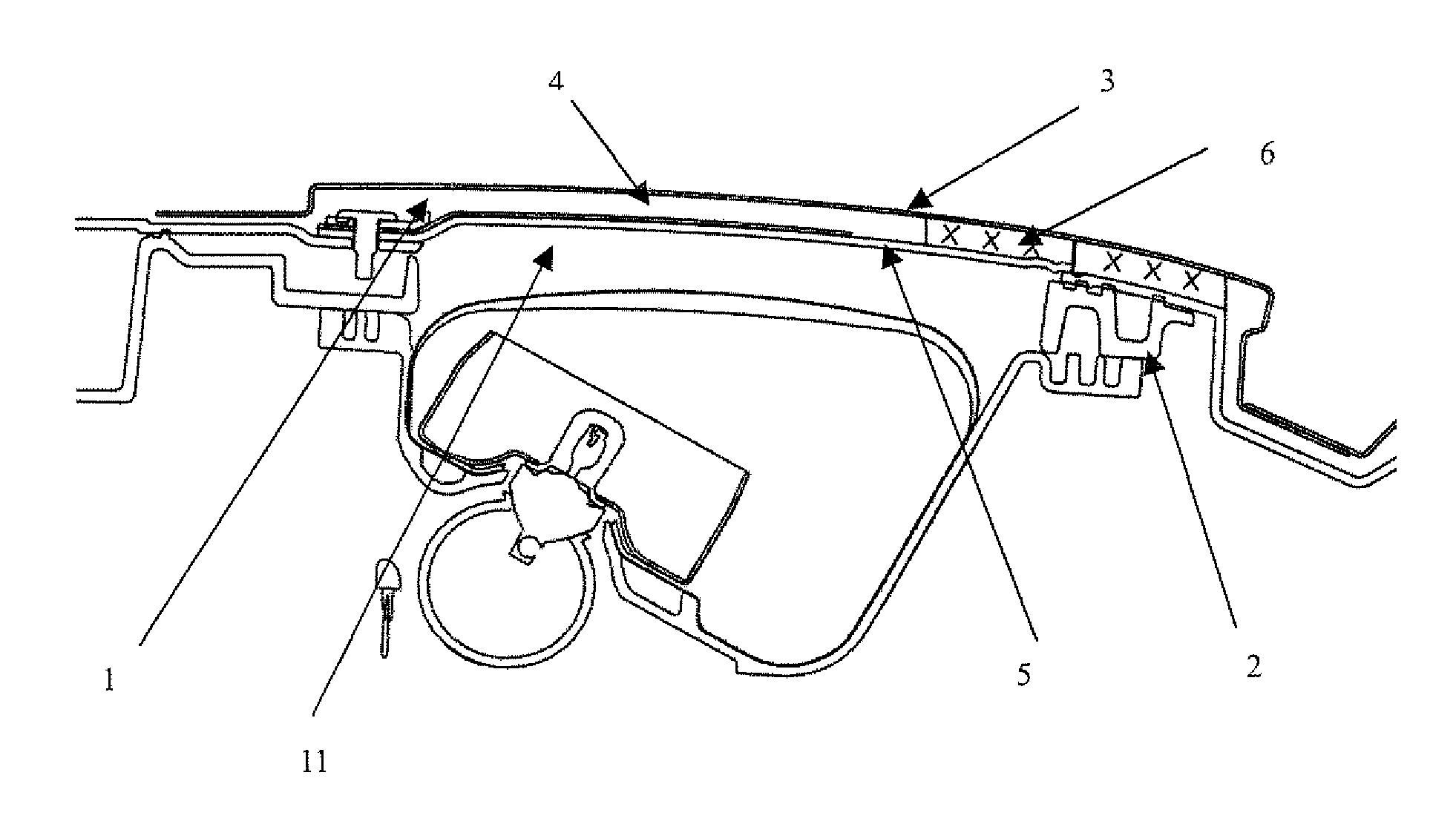

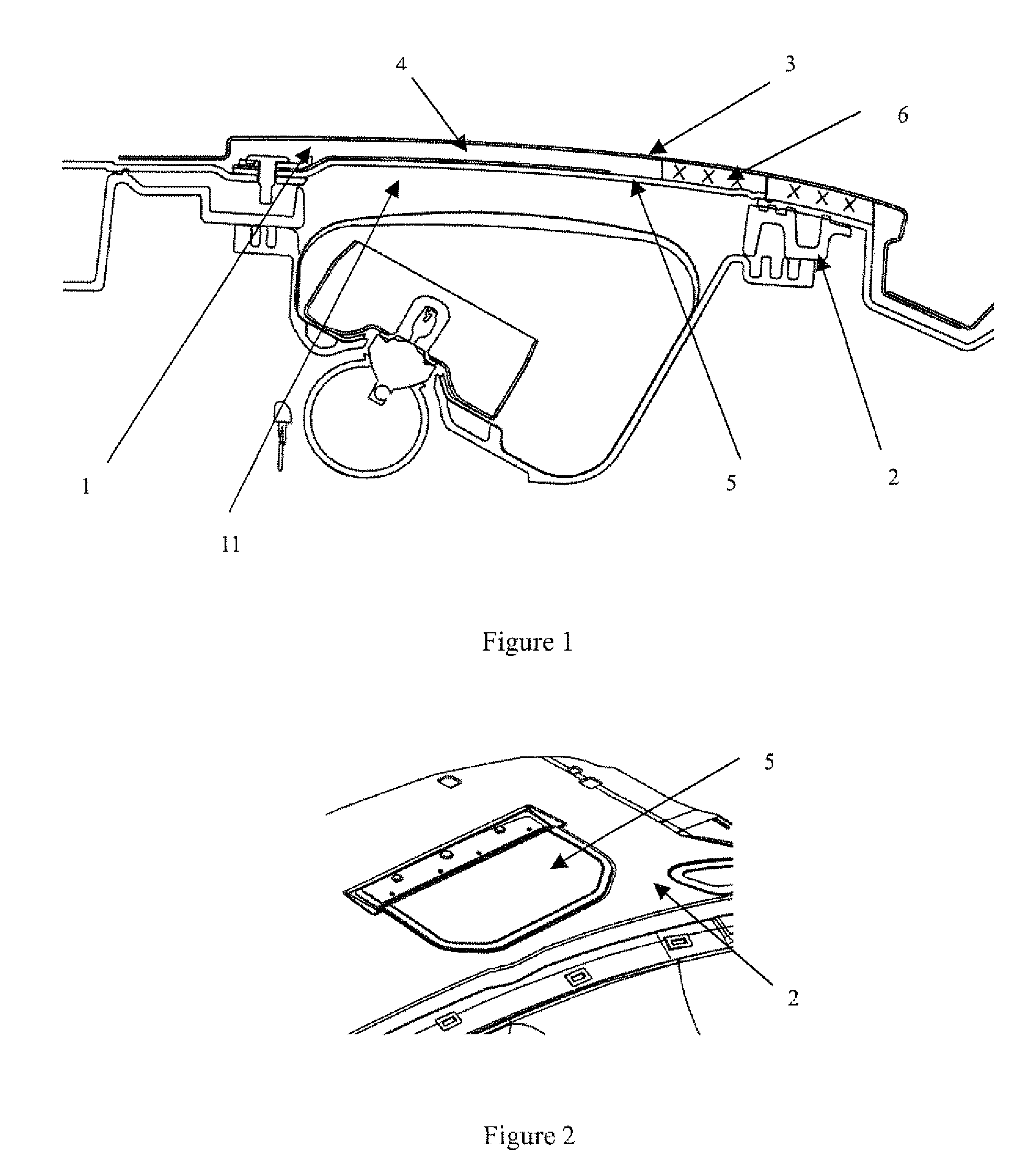

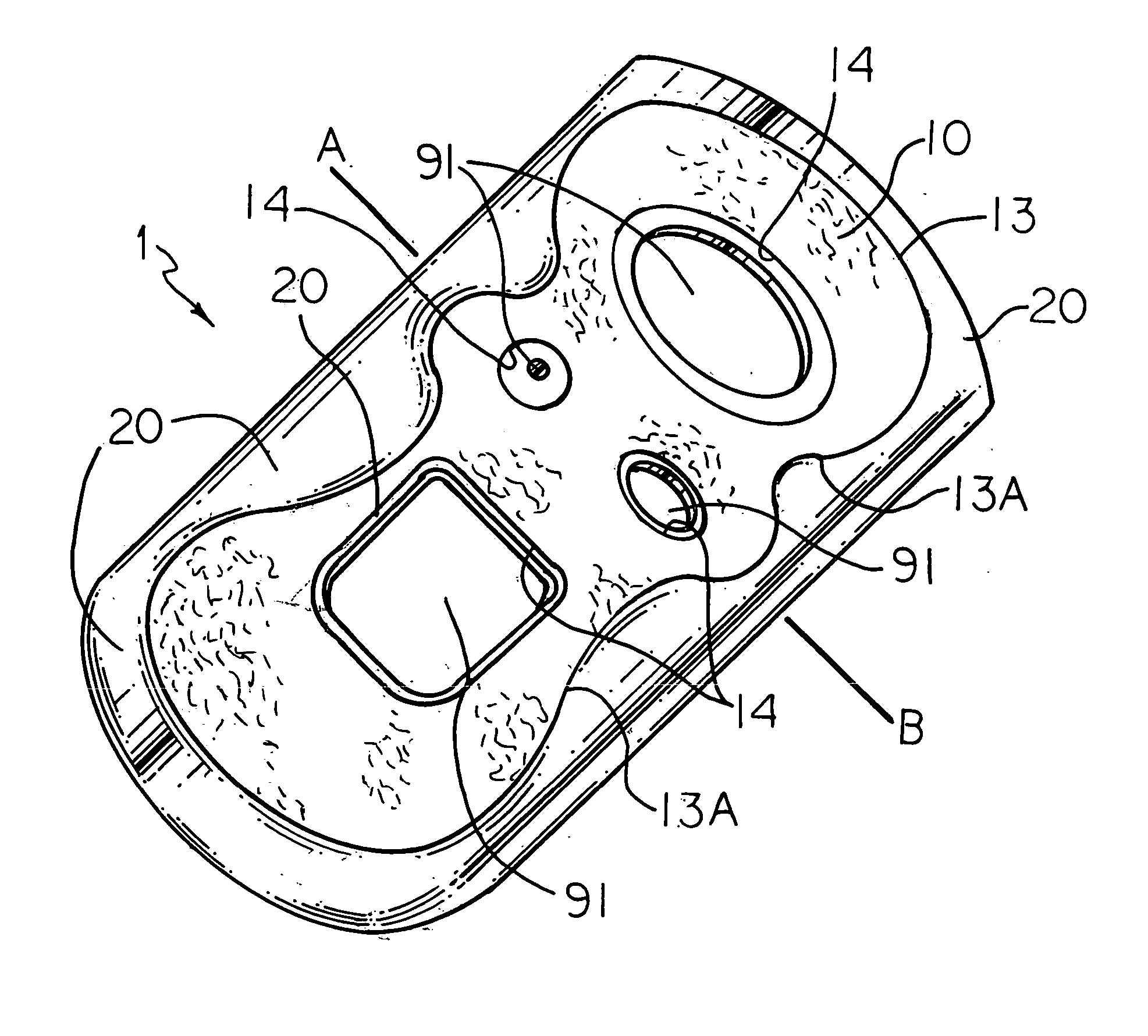

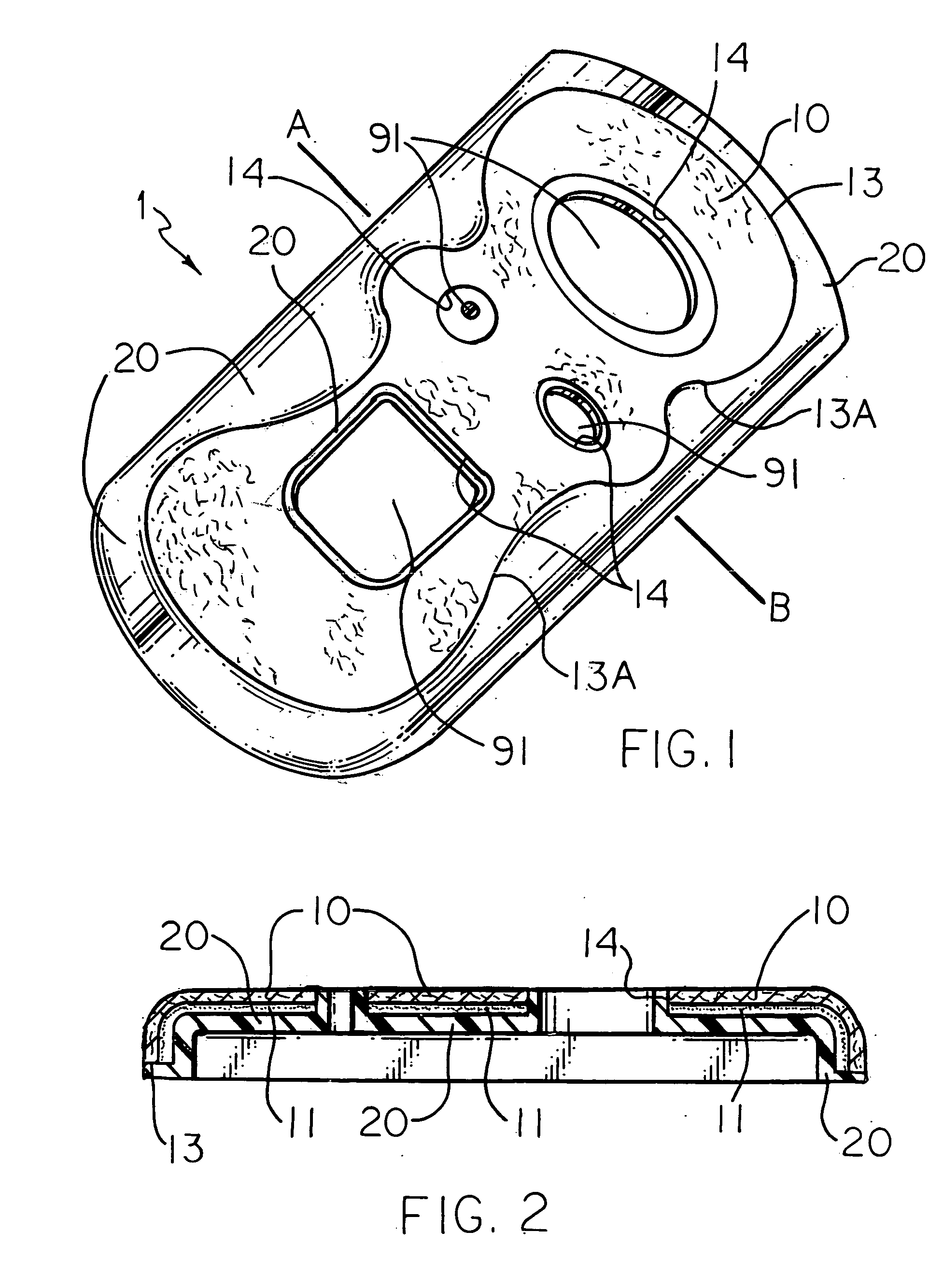

Automotive interior trim

ActiveUS7862071B2Improve deployment safetyAvoid material damagePedestrian/occupant safety arrangementSurface layerEngineering

An automotive interior trim for improving deployment safety of seamless passenger airbags for instrument panel is disclosed. The interior trim, mounted on an deployment opening of an airbag module of a framework for a instrument panel, includes a framework with an airbag deployment opening for a instrument panel, an airbag cover covering the airbag deployment opening, a foaming interlayer, a surface layer, and a netlike additional layer which is integrally combined with the foaming interlayer after penetrated by a foam material. When the airbag bursts, the airbag cover is opened outwards and the surface layer of the instrument panel is torn, and the foaming interlayer is torn thereupon too. Under the effect of the netlike additional layer, the foam in the foaming interlayer is fixed by the additional layer, thereby avoiding crumb and hard particle production and improving the deployment safety of the airbag greatly.

Owner:YANFENG AUTOMOTIVE TRIM SYST CO LTD +2

Film-clad battery and method of producing film-clad battery

ActiveUS8697277B2Avoid material damageSmall thicknessFinal product manufactureDouble layer capacitorsEngineering

Owner:NEC CORP

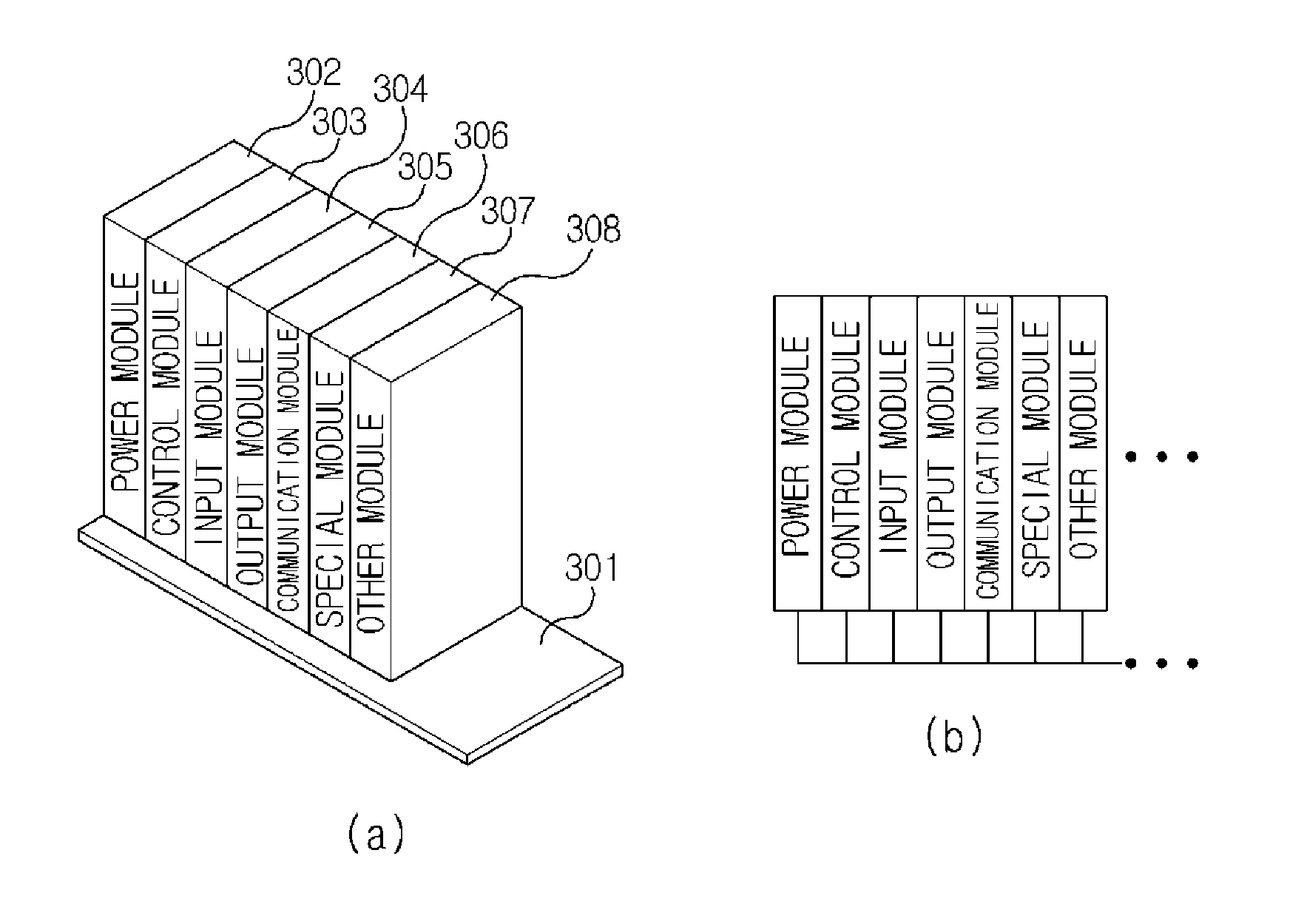

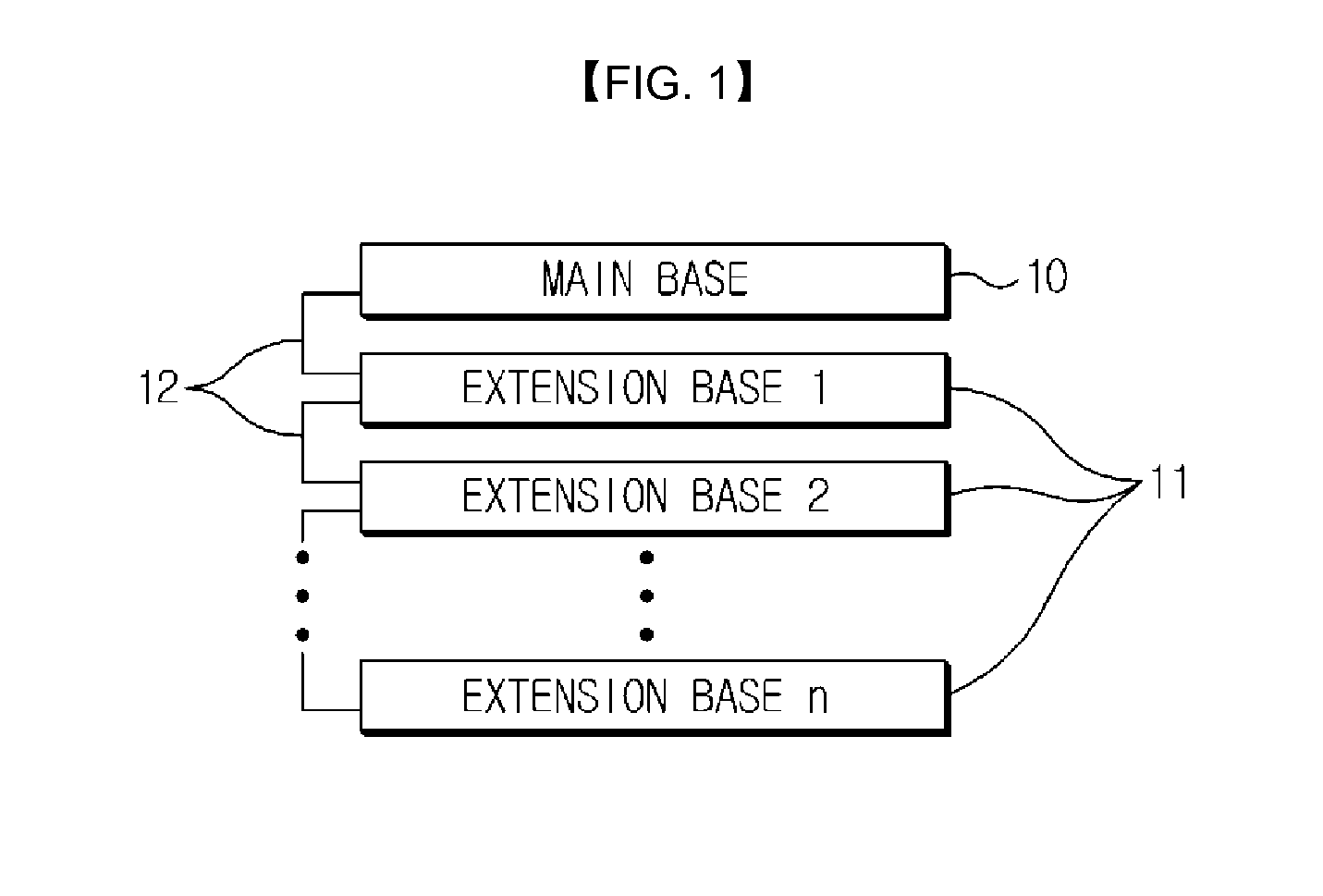

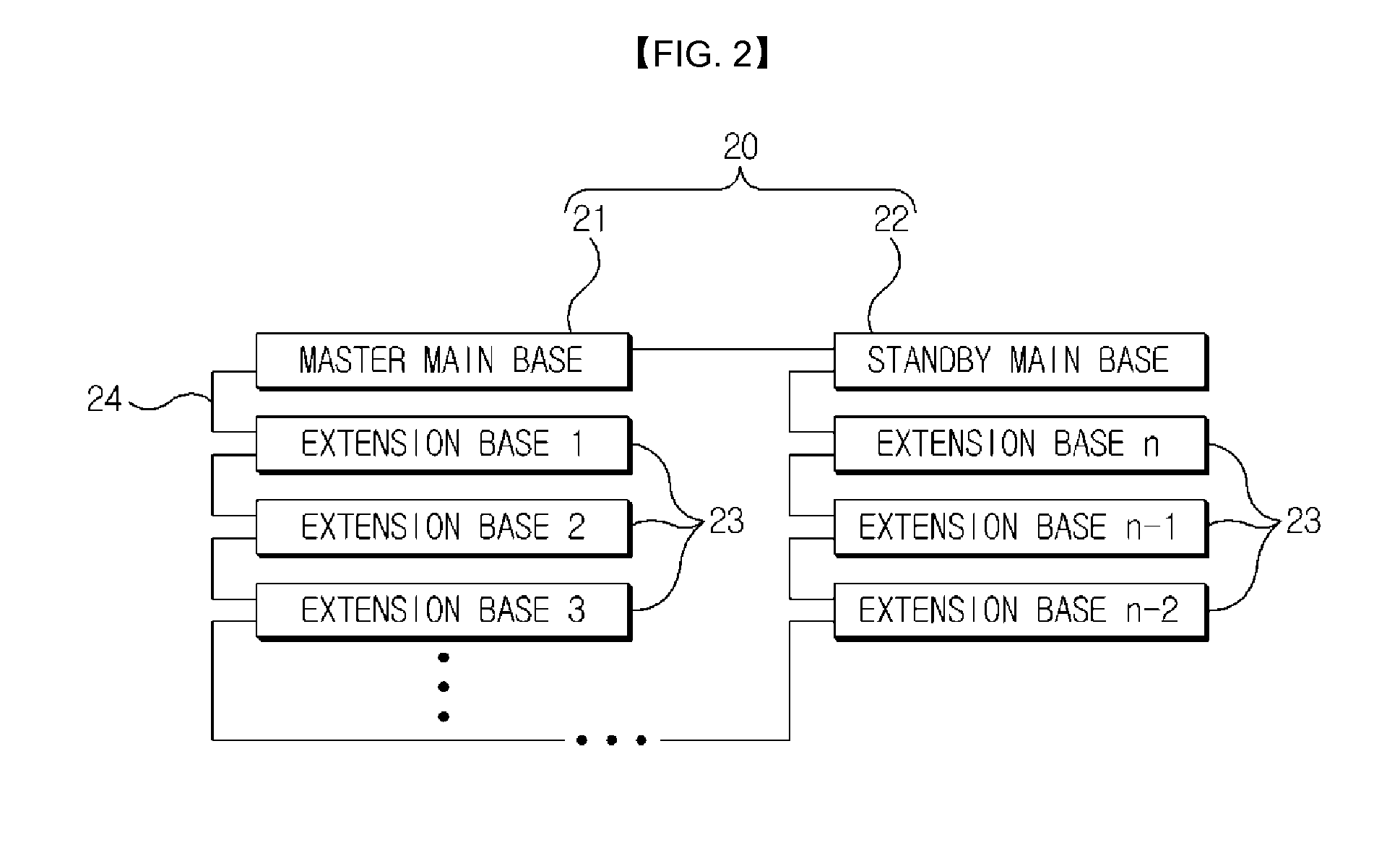

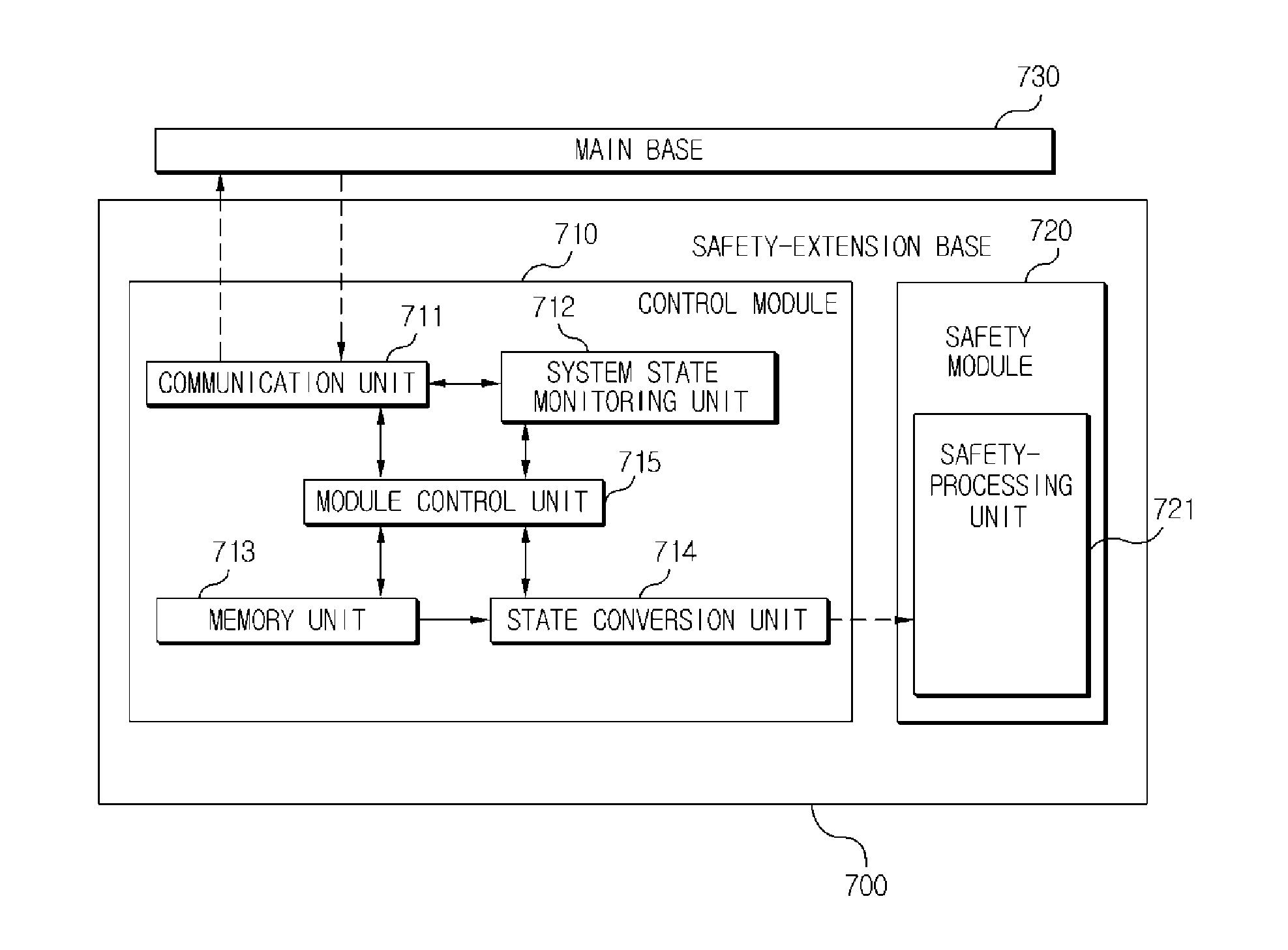

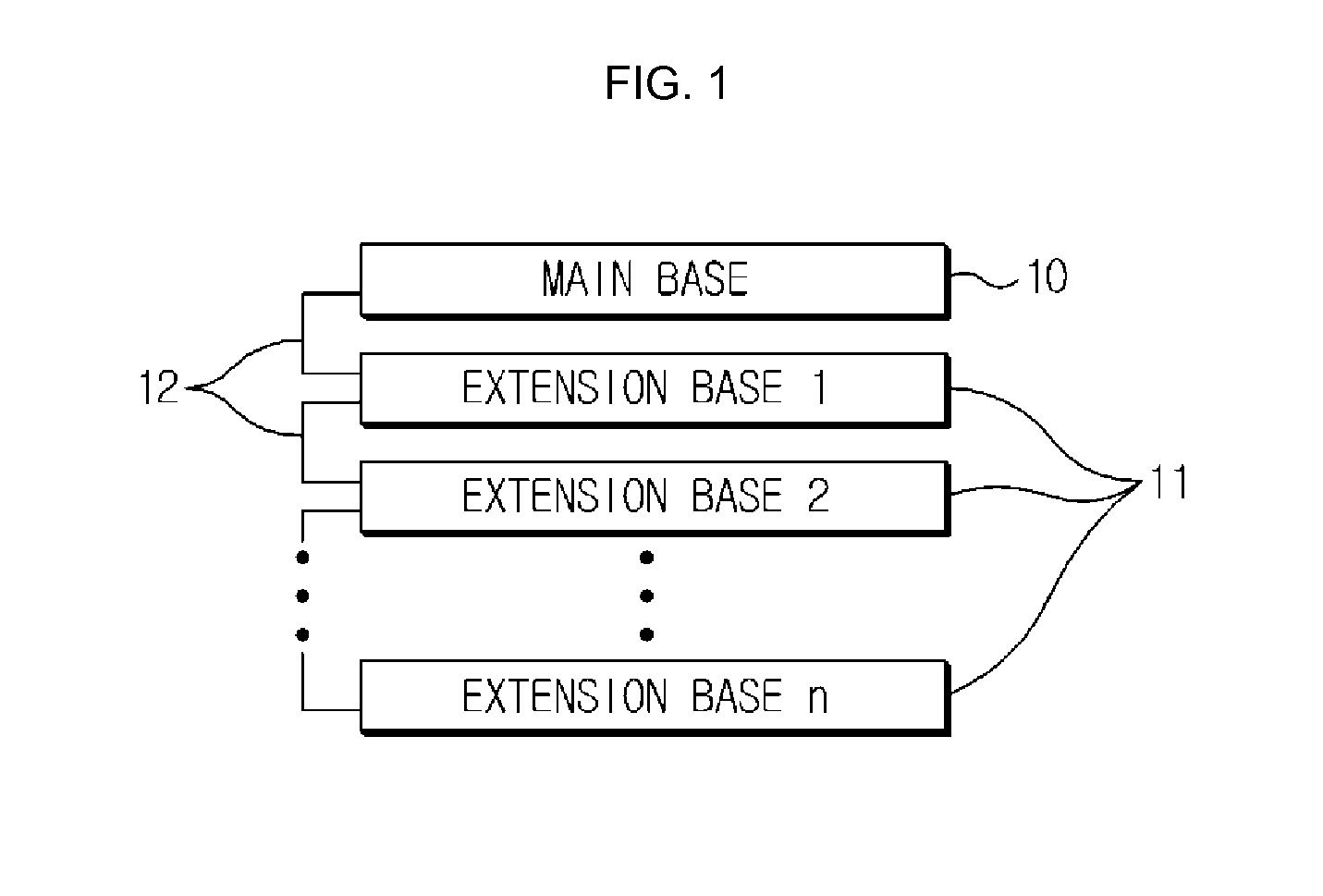

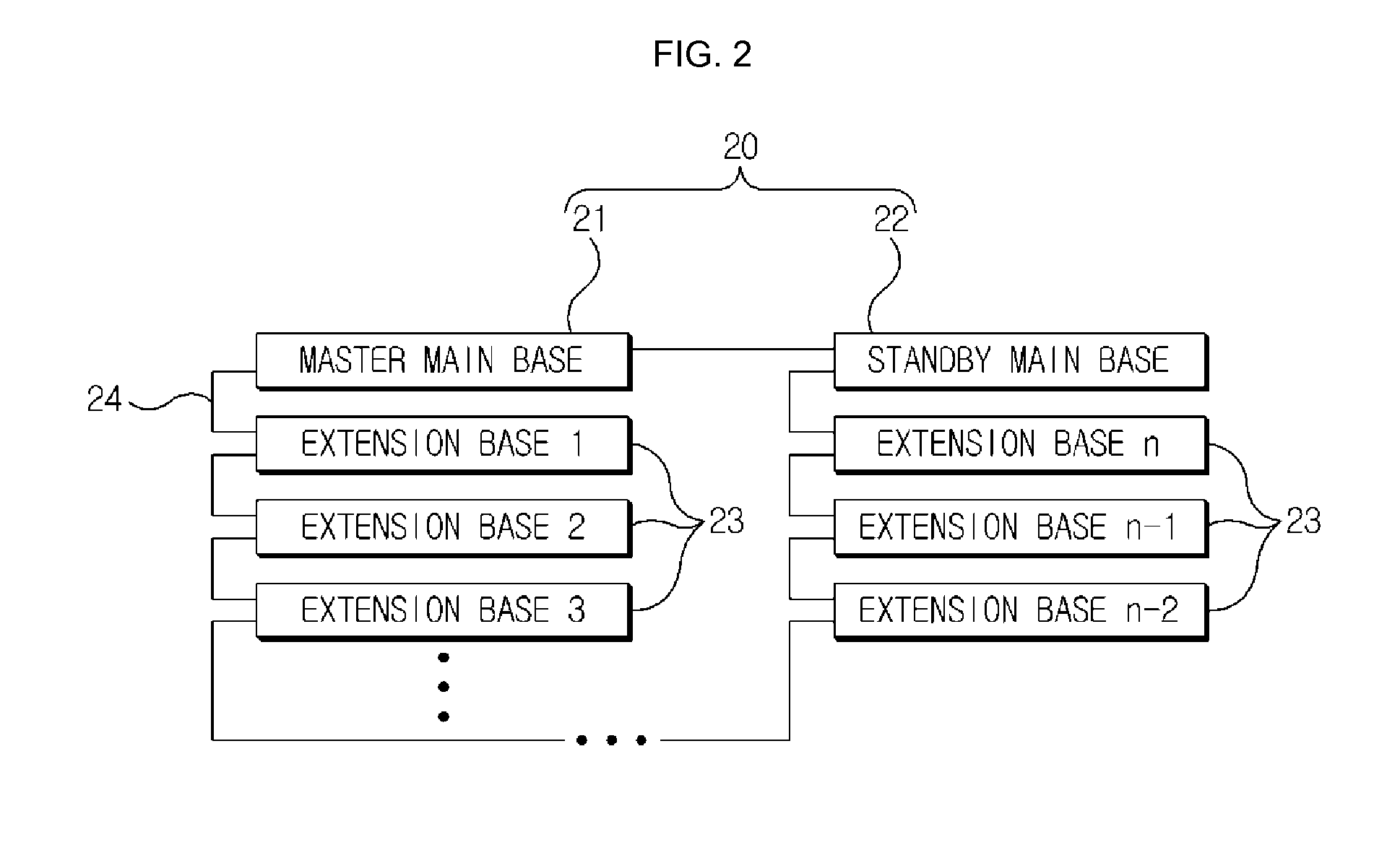

Safety-extension base and control method thereof

ActiveUS20120303143A1Prevent material damageAvoid material damageSafety arrangmentsBootstrappingMonitor unitStorage cell

A safety-extension base connected to a main base and a control method thereof are disclosed, the base includes a communication unit, a system state monitoring unit, a module control unit, a memory unit, a state conversion unit and a safety-processing unit. The communication unit performs data communication with the main base. The system state monitoring unit monitors a state of the PLC system. The module control unit controls a general operation of the safety-extension base and outputs different cases of control signals. The memory unit stores the data transmitted from the main base and a program and information. The state conversion unit converts the state of the safety-extension base into the normal state or safety state. The safety-processing unit performs a control of the safety-extension base.

Owner:LS IND SYETEMS CO LTD

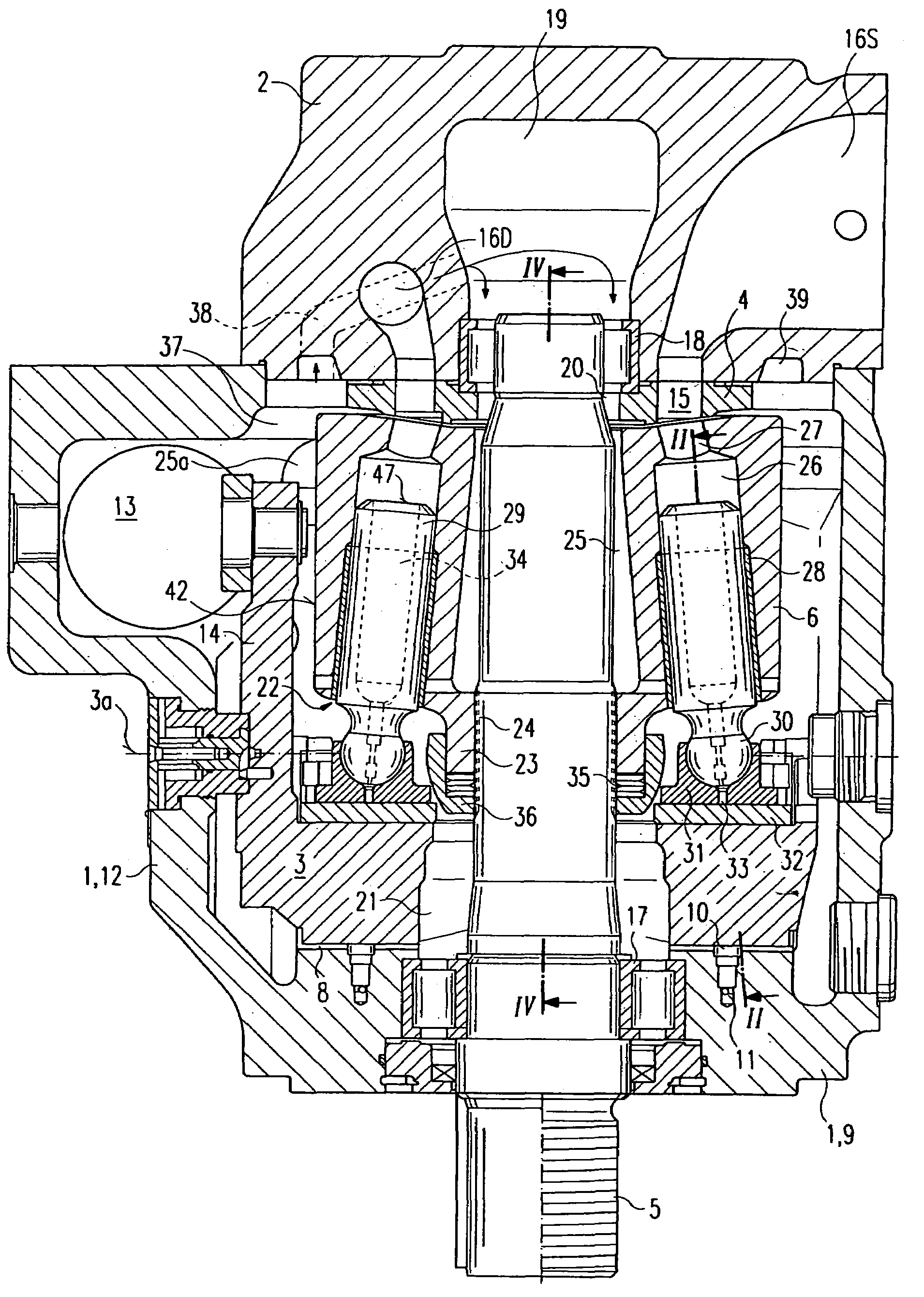

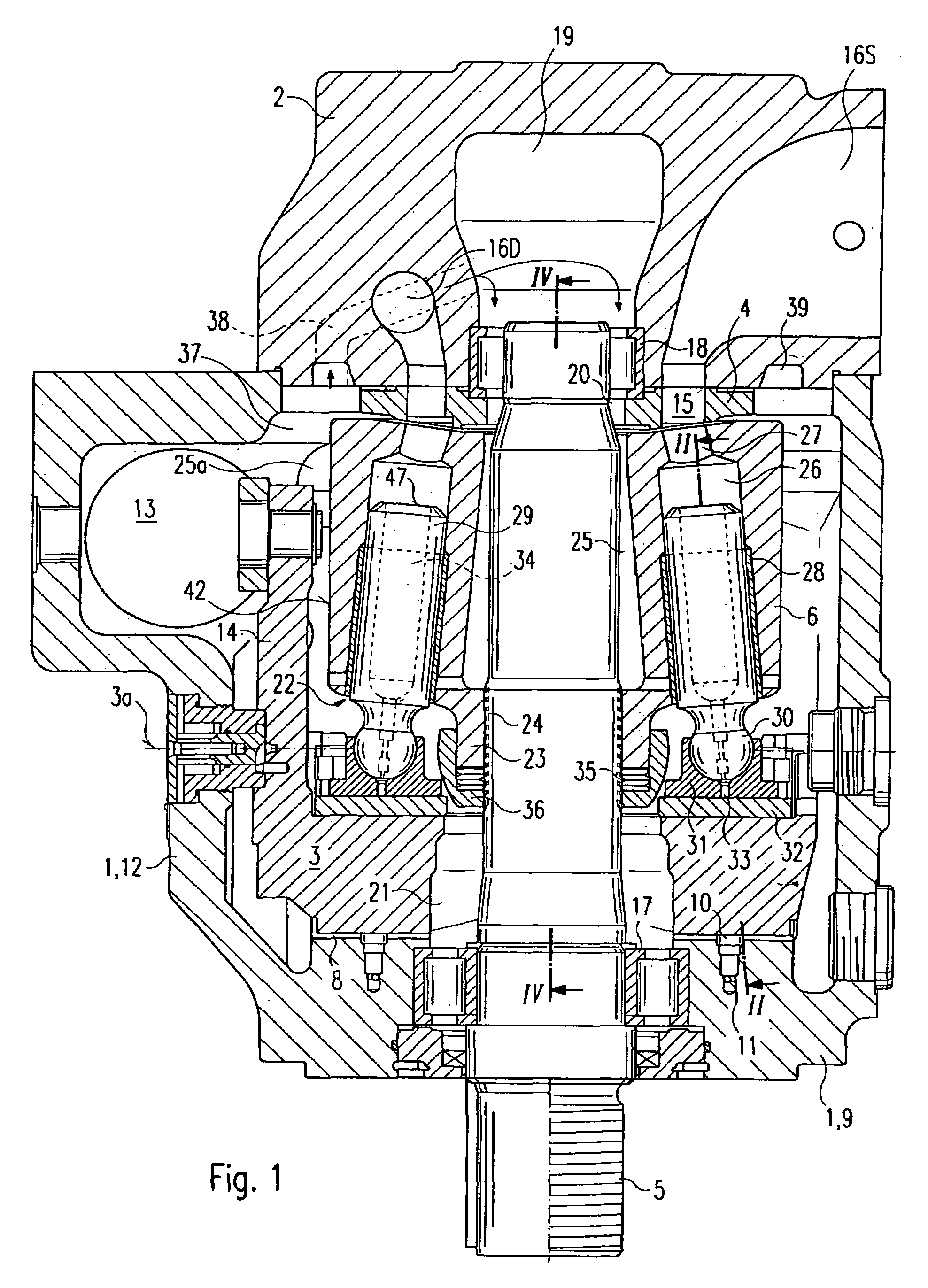

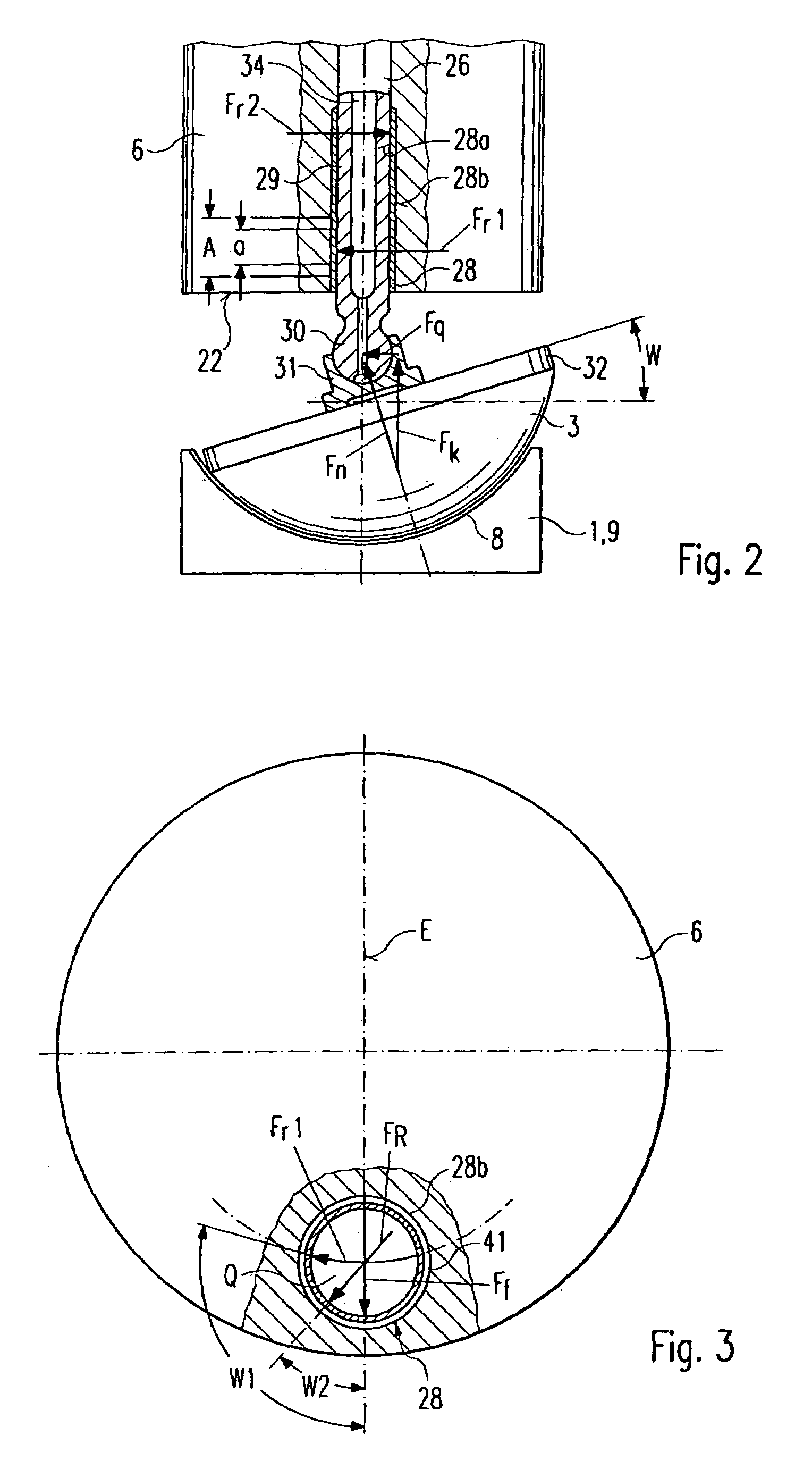

Hydrostatic machine with compensated sleeves

InactiveUS7073427B2Easy to manufactureEasy to assembleCylindersMulti-stage pumpsCylinder blockMechanical engineering

A hydrostatic machine with a cylinder block (6), within which sleeve holes (28b) are arranged, in which sleeves (28) sit, surrounding piston bores (28a) in which pistons (29) are mounted, such as to be displaced back and forth and the pistons (29) extend into the cylinder block (5) such as to define cylinders (26) with the front ends thereof. According to the invention, the risk of piston seizure can be reduced, whereby the sleeves (28) comprise an axially-defined recess (41) in the outer surface thereof, in the region facing away from the cylinder and the region with the greatest piston radial force, pressing the pistons (29) against the wall of the piston bore.

Owner:HYDROMATIK GMBH

Automotive interior trim

ActiveUS20090045609A1Avoid material damageImprove deployment safetyPedestrian/occupant safety arrangementSurface layerEngineering

An automotive interior trim for improving deployment safety of seamless passenger airbags for instrument panel is disclosed. The interior trim, mounted on an deployment opening of an airbag module of a framework for a instrument panel, includes a framework with an airbag deployment opening for a instrument panel, an airbag cover covering the airbag deployment opening, a foaming interlayer, a surface layer, and a netlike additional layer which is integrally combined with the foaming interlayer after penetrated by a foam material. When the airbag bursts, the airbag cover is opened outwards and the surface layer of the instrument panel is torn, and the foaming interlayer is torn thereupon too. Under the effect of the netlike additional layer, the foam in the foaming interlayer is fixed by the additional layer, thereby avoiding crumb and hard particle production and improving the deployment safety of the airbag greatly.

Owner:YANFENG AUTOMOTIVE TRIM SYST CO LTD +2

Molded parts with discontinuous fabric surface areas and processes for their production

InactiveUS20050225005A1Avoid material damageSolve the lack of adhesionWood working apparatusWoven fabricsHeat resistanceEngineering

The present invention thus provides a fabric-laminated plastic part and a novel process where the fabric that provides the surface is pre-laminated with a support layer and supplied into a molding process where a plastic substrate component is molded. The fabric surface piece is precisely located and securely bonded by selection of a support layer plastic material having sufficient heat resistance and / or thickness to sufficiently resist melt softening and stretching during the molding process. This process and fabric laminated plastic article are especially suited for preparing thin-wall, articles that need to have precisely located, smooth fabric surface areas corresponding to discontinuities, voids or openings in the underlying molded plastic article.

Owner:MARCHBANKS ERIC L +6

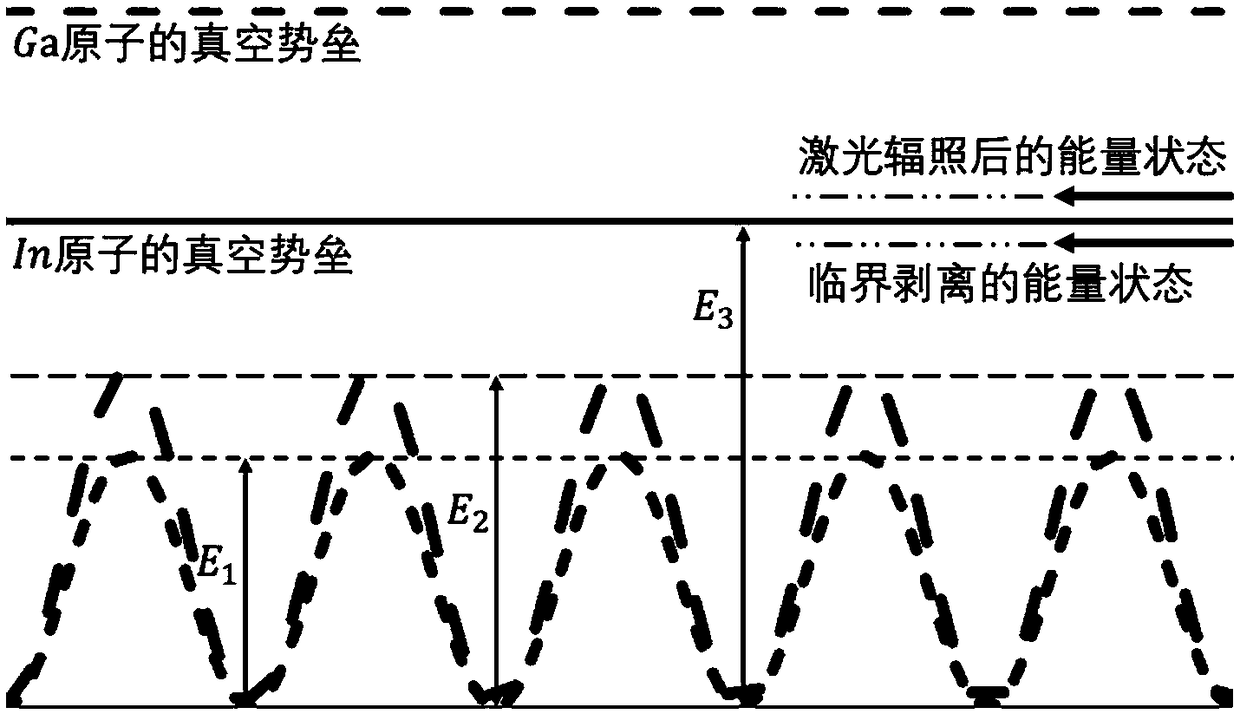

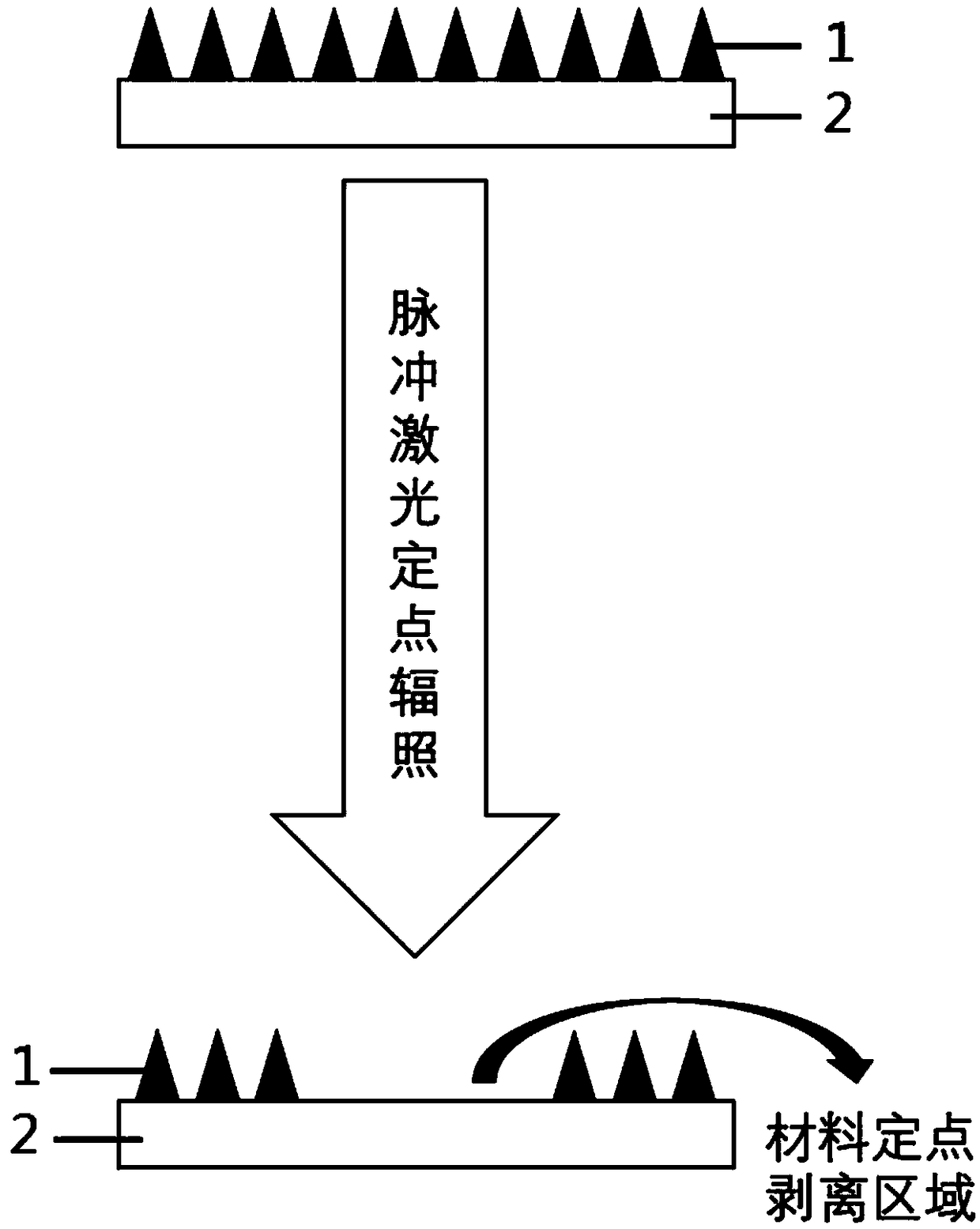

Method for in situ non-destructive stripping of quantum dots

ActiveCN108751254AReduce the effect of anisotropyAvoid material damageMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsPhysicsBond energy

The invention relates to a method for in situ non-destructive stripping of quantum dots. The method comprises the following steps: heating a substrate having quantum dots on the surface thereof to thecritical desorption temperature of quantum dots, wherein the quantum dots are III-V group quantum dots, the material of the substrate is a III-V compound, and the bond energy of the quantum dots is lower than the bond energy of the compound in the substrate; then applying pulse laser to the quantum dots, so that the atoms in the quantum dots are excited and detached in situ from the surface of the substrate. The method provided by the invention can effectively avoid the problems of oxidation, pollution, material destruction, time consuming and diseconomy existing in current mainstream stripping methods.

Owner:SUZHOU UNIV

Topographically defined thin film cpp read head

InactiveUS20080062576A1Inhibit currentEasy to solveNanoinformaticsHeads using thin filmsInsulation layerEngineering

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

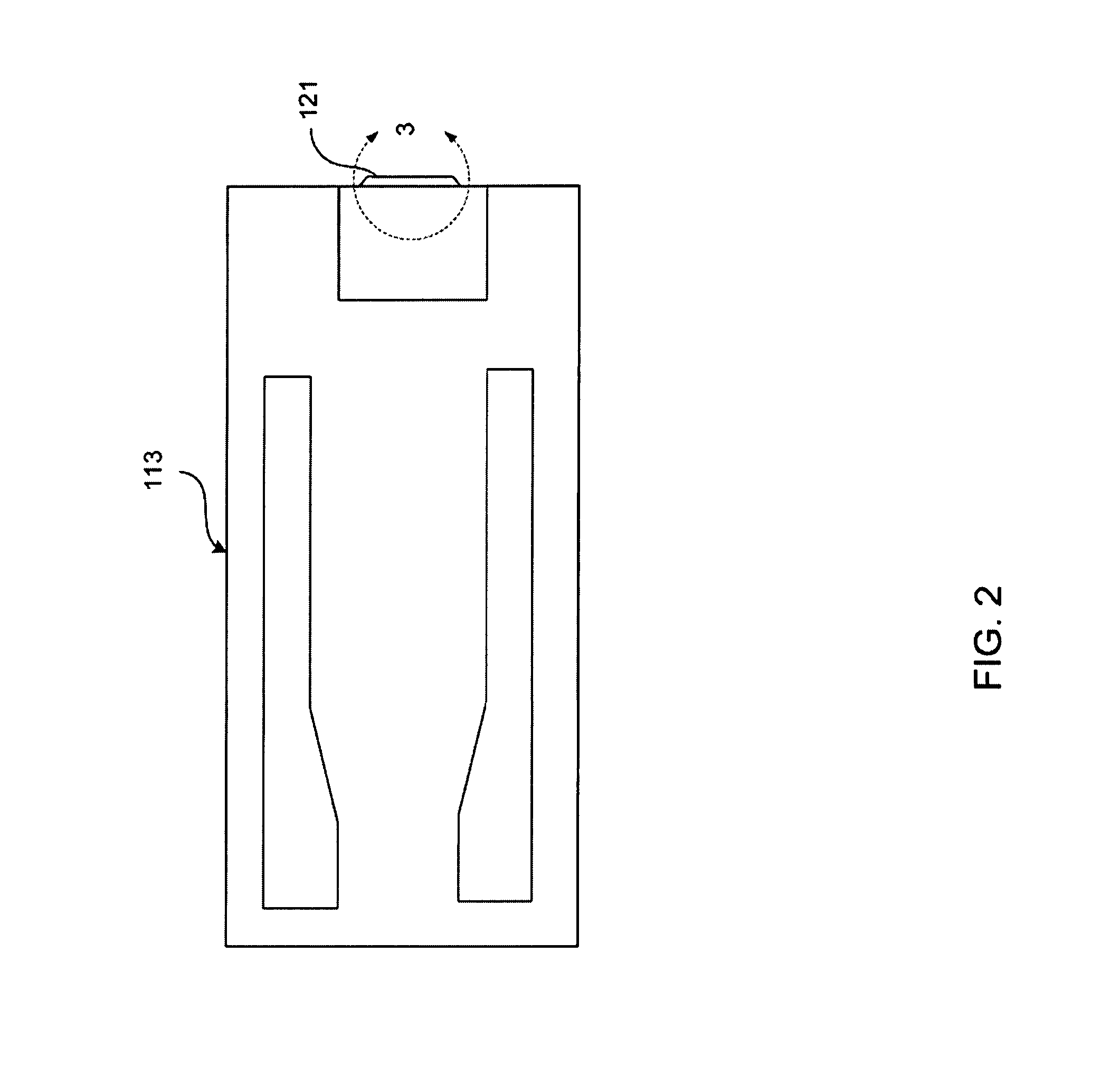

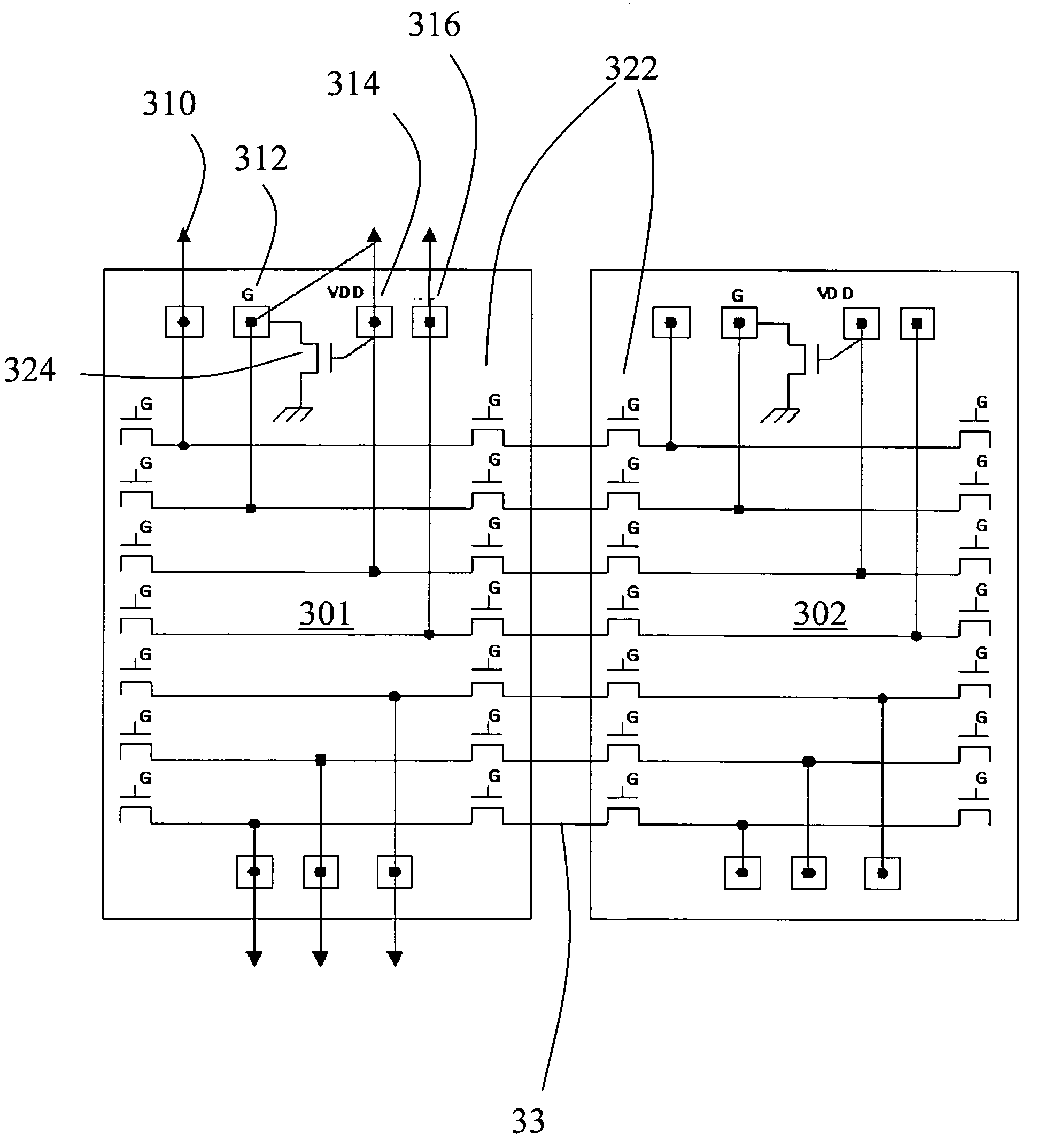

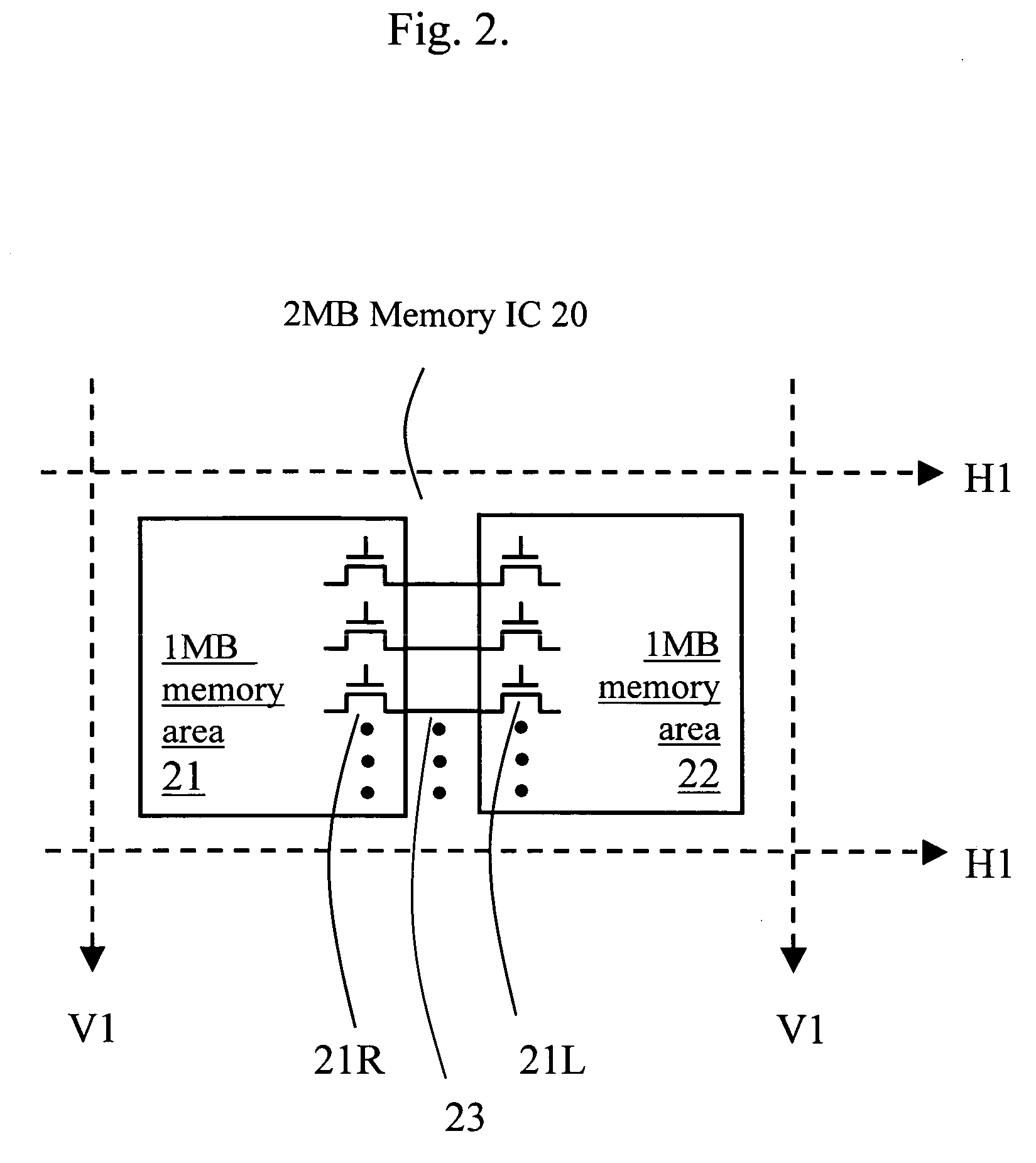

Capacity dividable memory IC

InactiveUS7190604B2Different capacity memoryAvoid material damageDigital storageMemory chipEngineering

Two memory areas on a wafer are coupled through pass transistors to double the memory capacity of each area and can be sawed to yield two memory chips each with single memory area. A pair of pass transistors are used to couple each dedicated functional pad in both memory areas, when the pass transistors are turned on. The connection between the pass transistor pair can be sawed through to yield single capacity memory dice. The memory capacity can be further increased by coupling more memory areas together with pass transistors.

Owner:LYONTEK

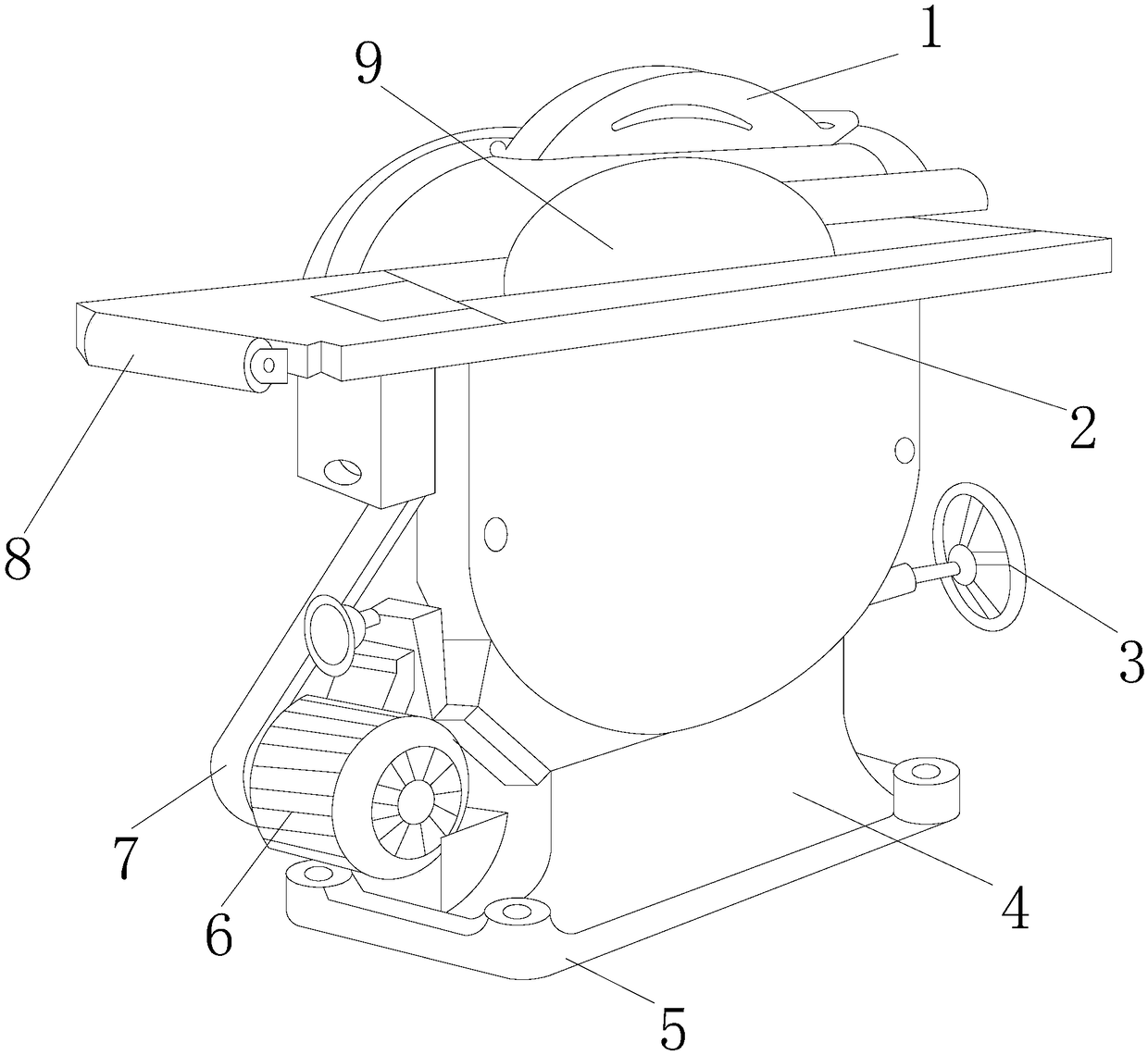

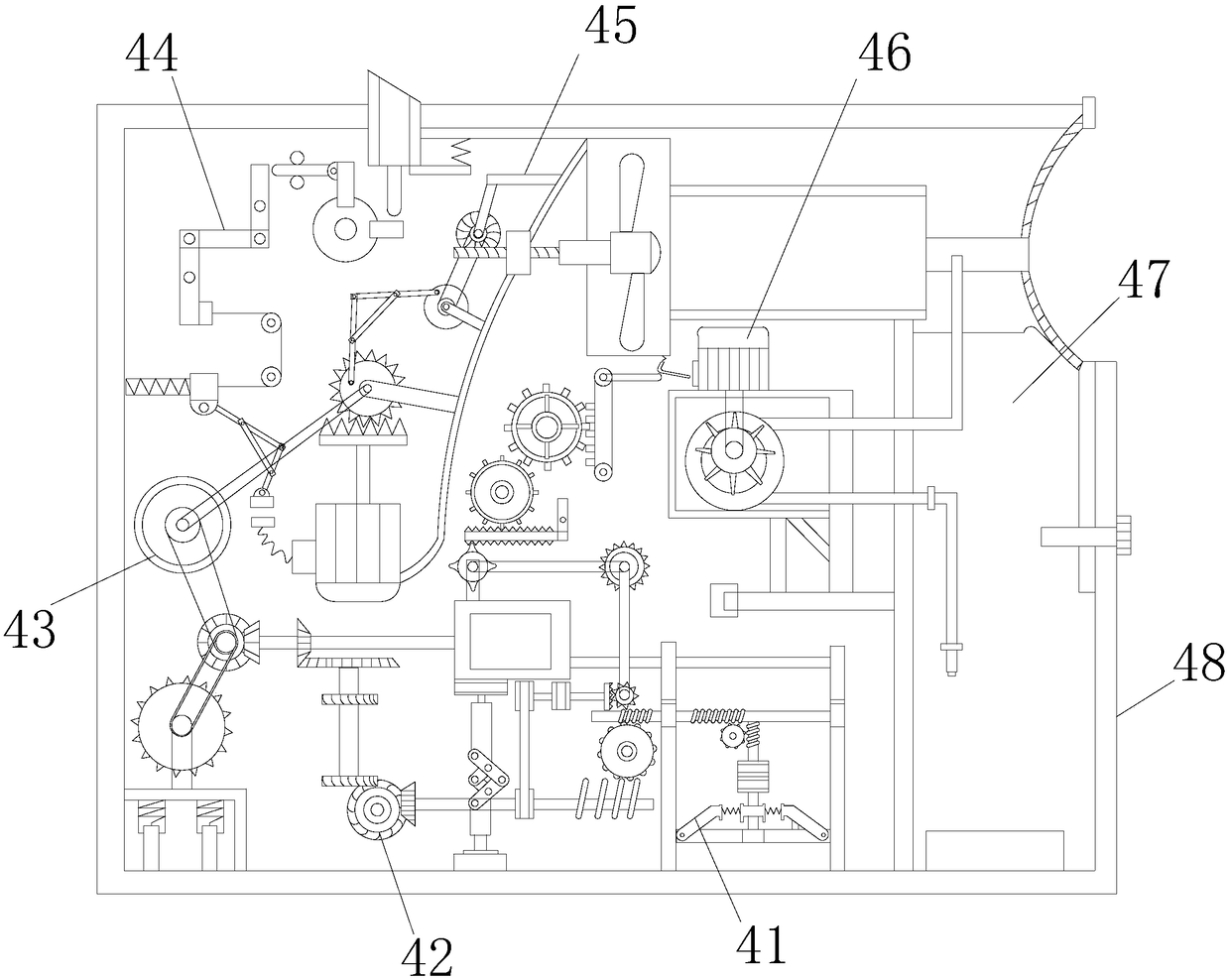

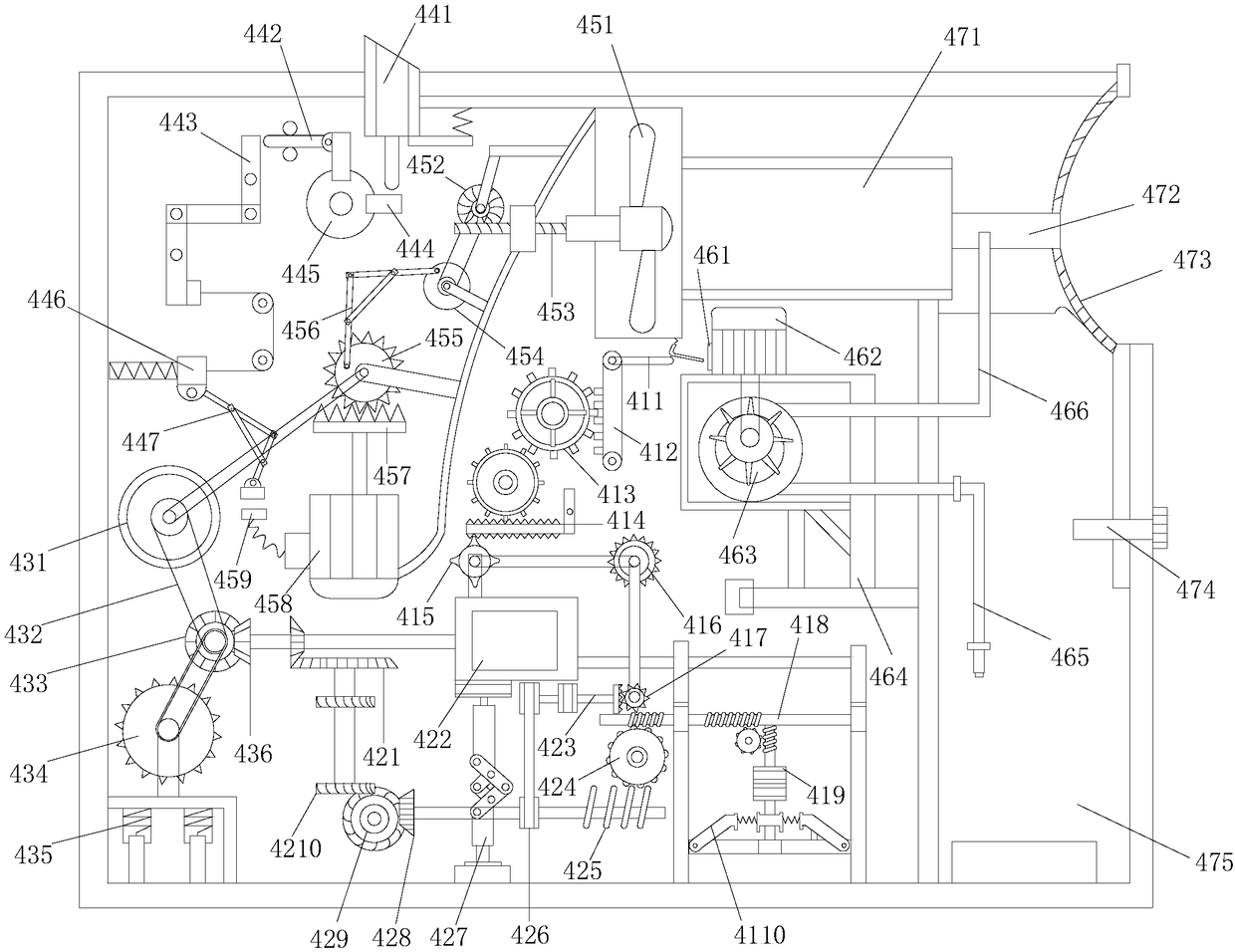

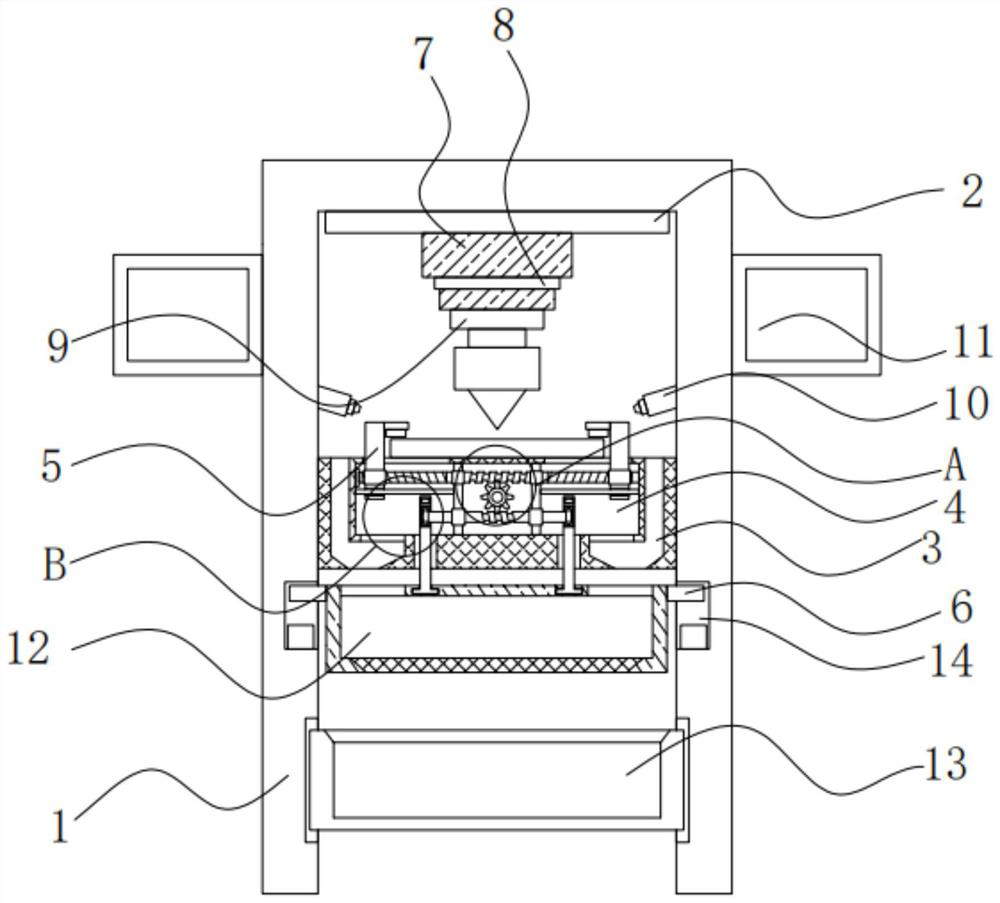

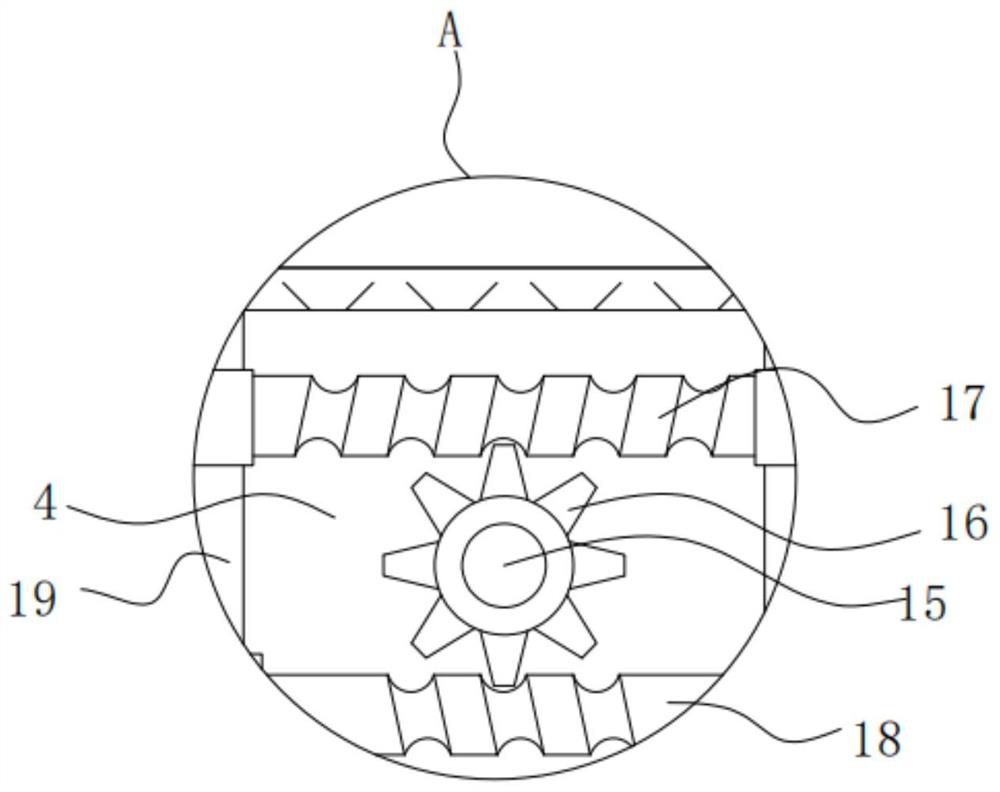

Dustproof type wood cutting device

InactiveCN108943188AAvoid material damageExtended service lifeProfiling/shaping machinesRotary valveSmall hole

The invention discloses a dustproof type wood cutting device. The dustproof type wood cutting device structurally comprises a cutting blade protection cover, a working chamber, a rotary valve, a cooling device, a supporting board, an engine, a transmission belt, a working platform and a cutting blade; the cutting blade is fixed to the upper portion of the interior of the working chamber through ascrew; and the cooling device is provided with a movable adjusting device, a fixed linkage device, a stress drive device, a screw starting device, an air blower device, a water pump device, a stress mist spraying device and a metal frame. The dustproof type wood cutting device has the beneficial effects that by additionally arranging the cooling device, air flows out rapidly from a small hole according to the Bernoulli principle, the pressure intensity near the small hole is small, the pressure intensity of air on the liquid face in a container is large, liquid rises along a thin pipe below the small hole, flows out from an upper opening of the thin pipe and is sprayed to be in a mist shape under impact of air flow to cool a cutter wheel, the cutter wheel is effectively cooled, material damage caused by too high temperature is avoided, and the service life of a cutting machine is prolonged.

Owner:张晓晶

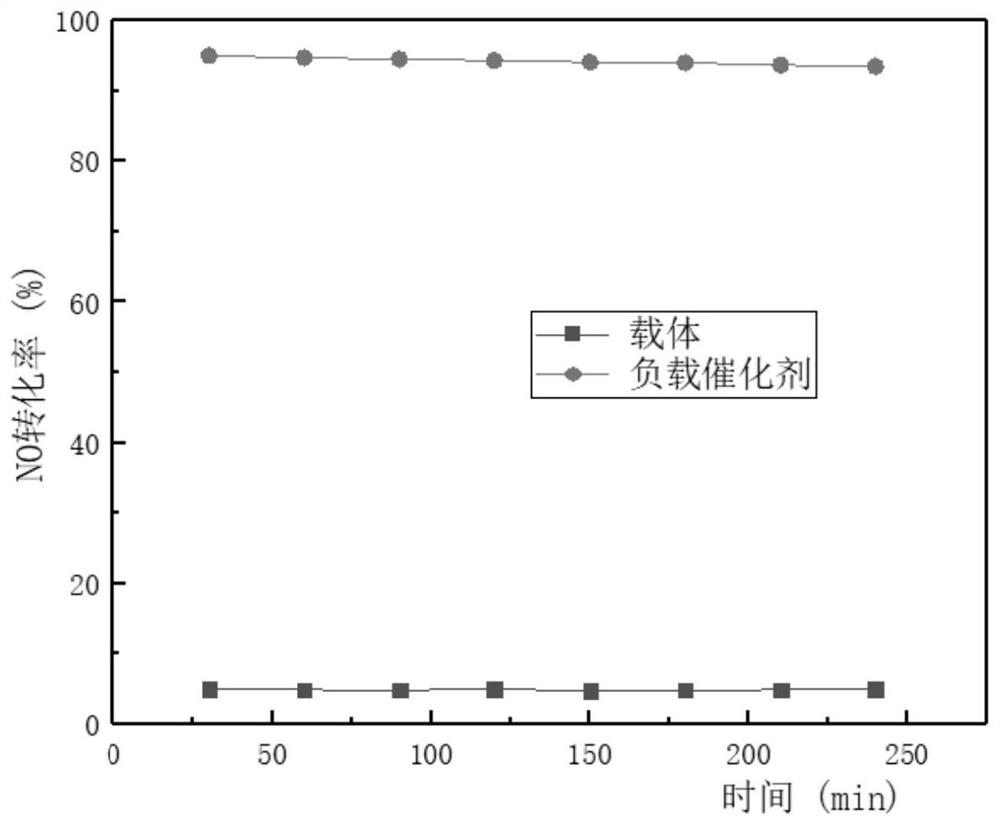

Purification treatment method for tail gas of a diesel engine

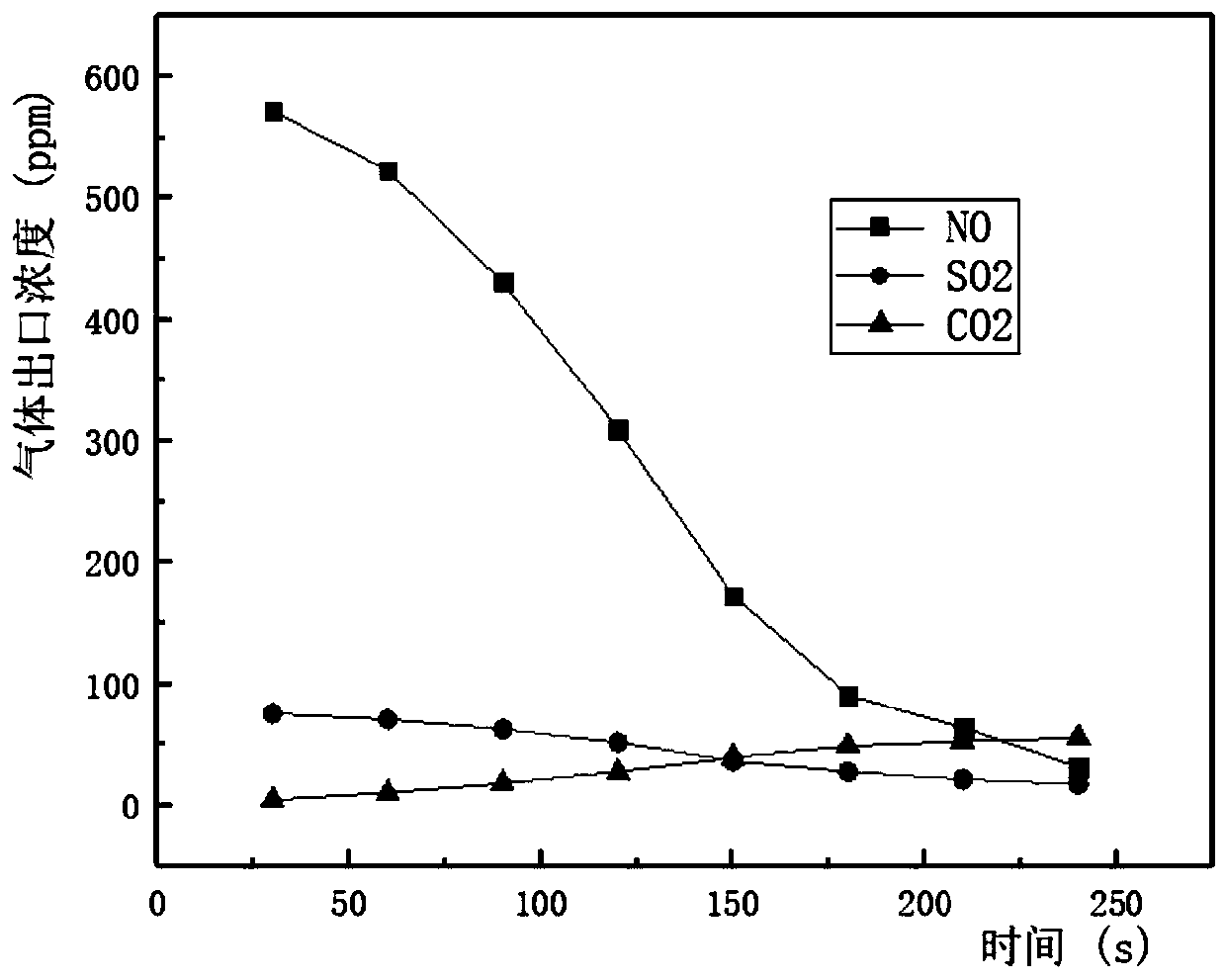

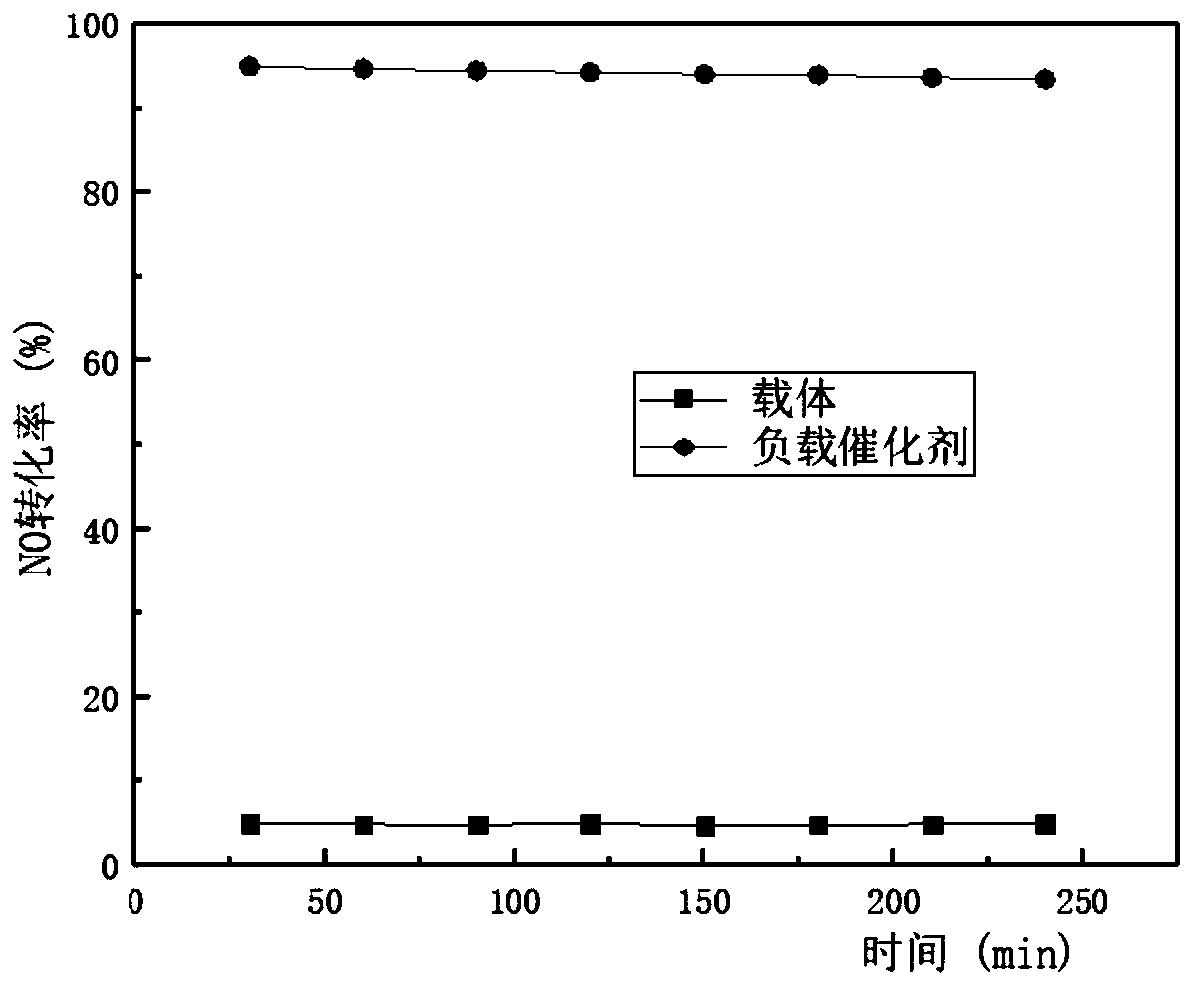

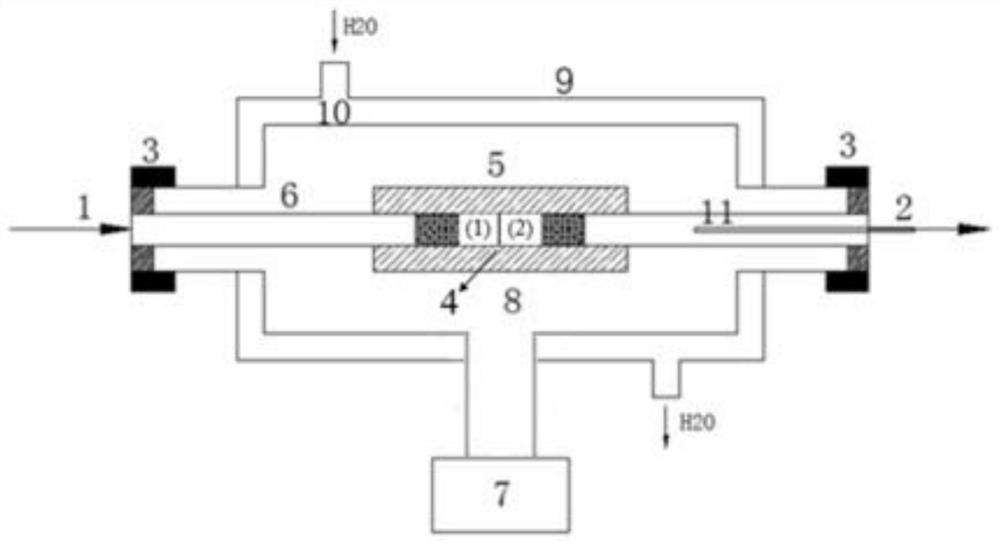

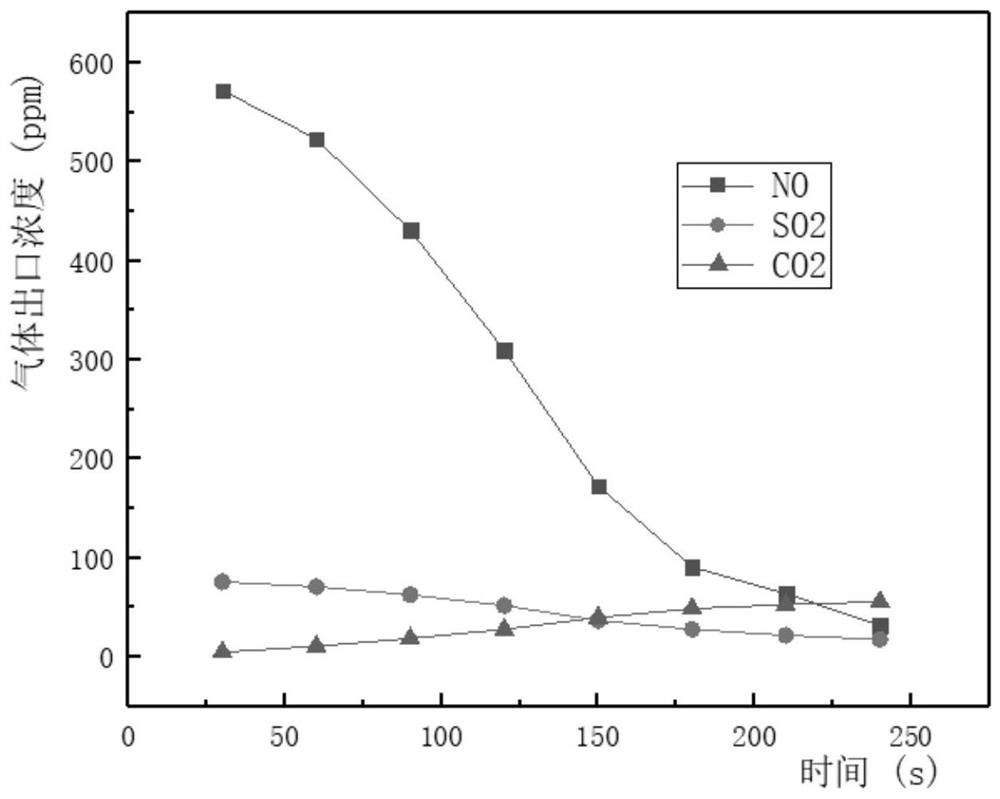

ActiveCN111408379AEasy to handleSolve the blockageGas treatmentHeterogenous catalyst chemical elementsParticulatesCerium

The invention relates to a purification treatment method for tail gas of a diesel engine. The method comprises the steps of: providing an exhaust gas treatment catalyst, wherein the catalyst comprisesa zinc oxide honeycomb ceramic carrier and a catalyst body loaded on the carrier, the zinc oxide honeycomb ceramic carrier is a wave-absorbing heating zinc oxide honeycomb ceramic material and can capture and adsorb particles in diesel engine tail gas, and the particles adsorbed to the surface of ceramic are further combusted and decomposed under the microwave heating effect. Meanwhile, sulfur dioxide in tail gas of the diesel engine can be absorbed, so that the desulfurization purpose is achieved. In addition, the material is loaded with a lanthanum-cerium-nickel composite metal oxide catalyst, and has a good denitration effect on tail gas of a diesel engine in a microwave field. According to the purification treatment method based on the carrier and the catalyst, the reaction efficiencyof the catalyst can be effectively improved, catalyst poisoning is avoided, the service life of the catalyst is prolonged, and the purification treatment method has wide application prospects in thefield of diesel engine tail gas purification.

Owner:WUHAN UNIV OF TECH

A kind of purification treatment method of diesel engine exhaust

ActiveCN111408379BAvoid poisoningAvoid failureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention relates to a method for purifying and treating exhaust gas of a diesel engine. Provide exhaust gas treatment catalysts, including zinc oxide honeycomb ceramic carrier and catalyst loaded on the carrier, wherein the zinc oxide honeycomb ceramic carrier is a microwave-absorbing and exothermic zinc oxide honeycomb ceramic material, which can trap and adsorb particulate matter in diesel engine exhaust, and in Under the action of microwave heating, the particles adsorbed on the ceramic surface are further burned and decomposed. At the same time, it can absorb sulfur dioxide in the exhaust gas of diesel engines, so as to achieve the purpose of desulfurization. In addition, the material supports a lanthanum-cerium-nickel composite metal oxide catalyst, which has a good denitrification effect on the exhaust gas of a diesel engine under a microwave field. The purification treatment method provided based on the above-mentioned carrier and catalyst can effectively improve the reaction efficiency of the catalyst, avoid catalyst poisoning and prolong its service life, and has broad application prospects in the field of purification of diesel engine exhaust.

Owner:WUHAN UNIV OF TECH

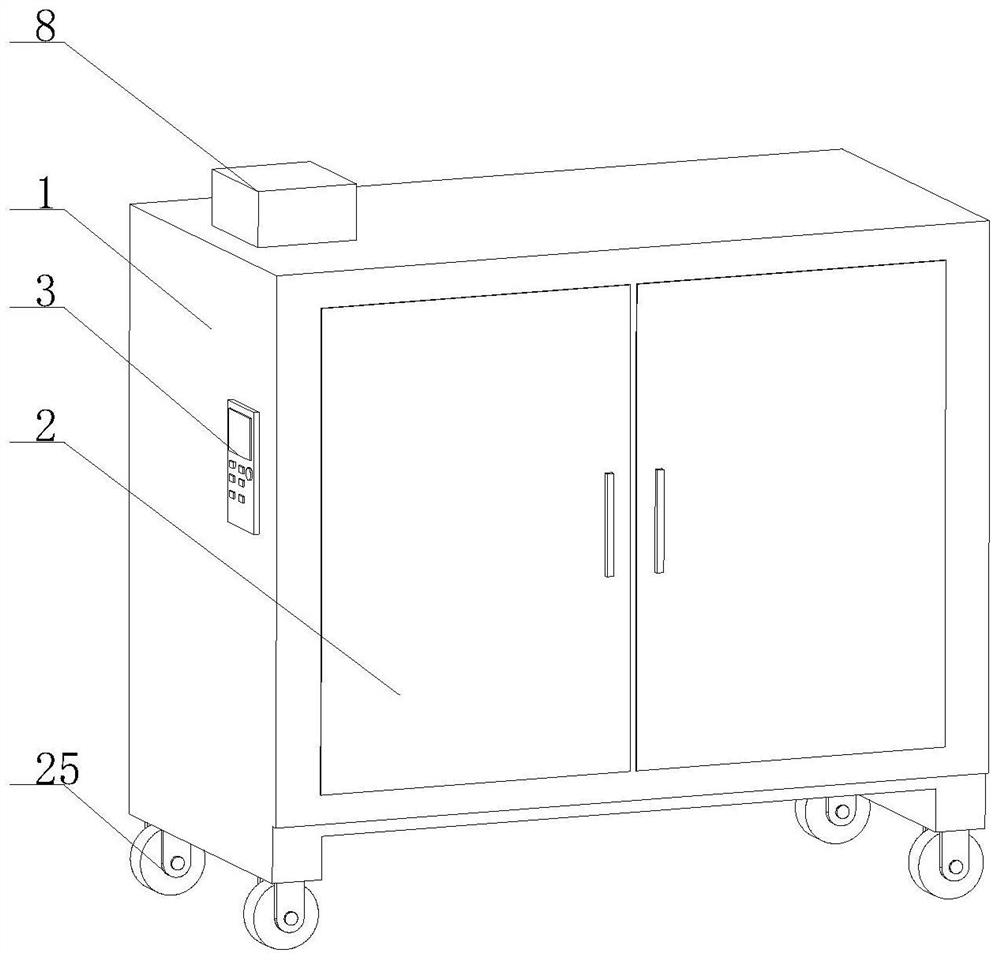

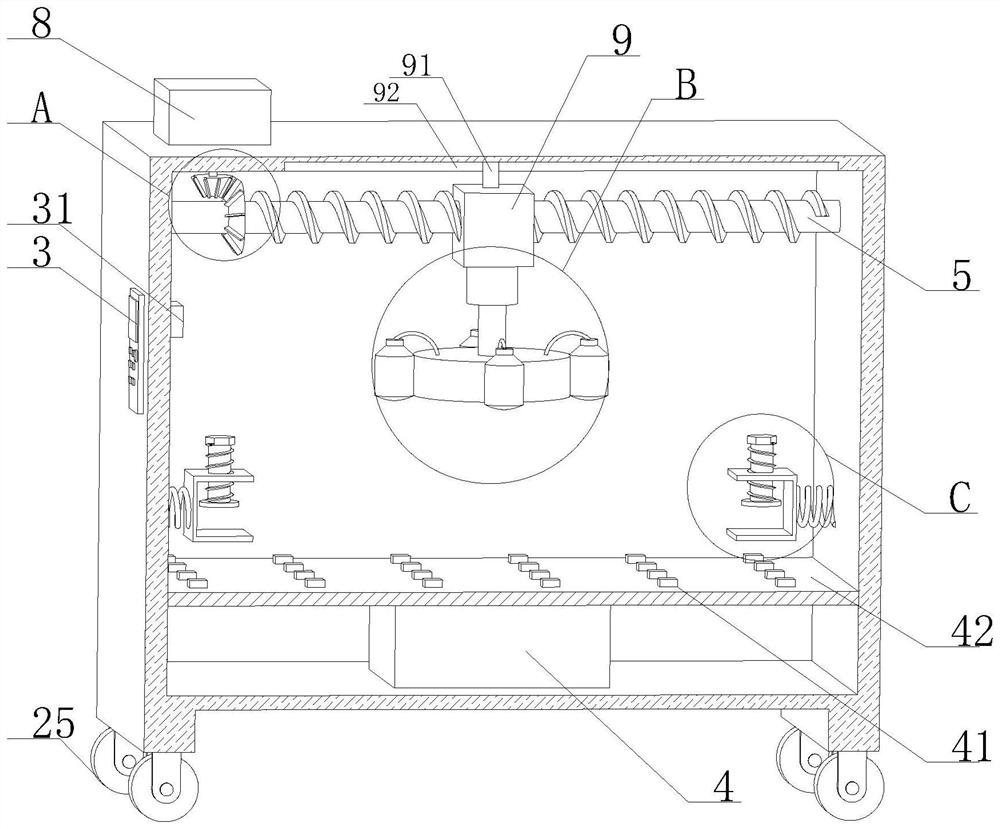

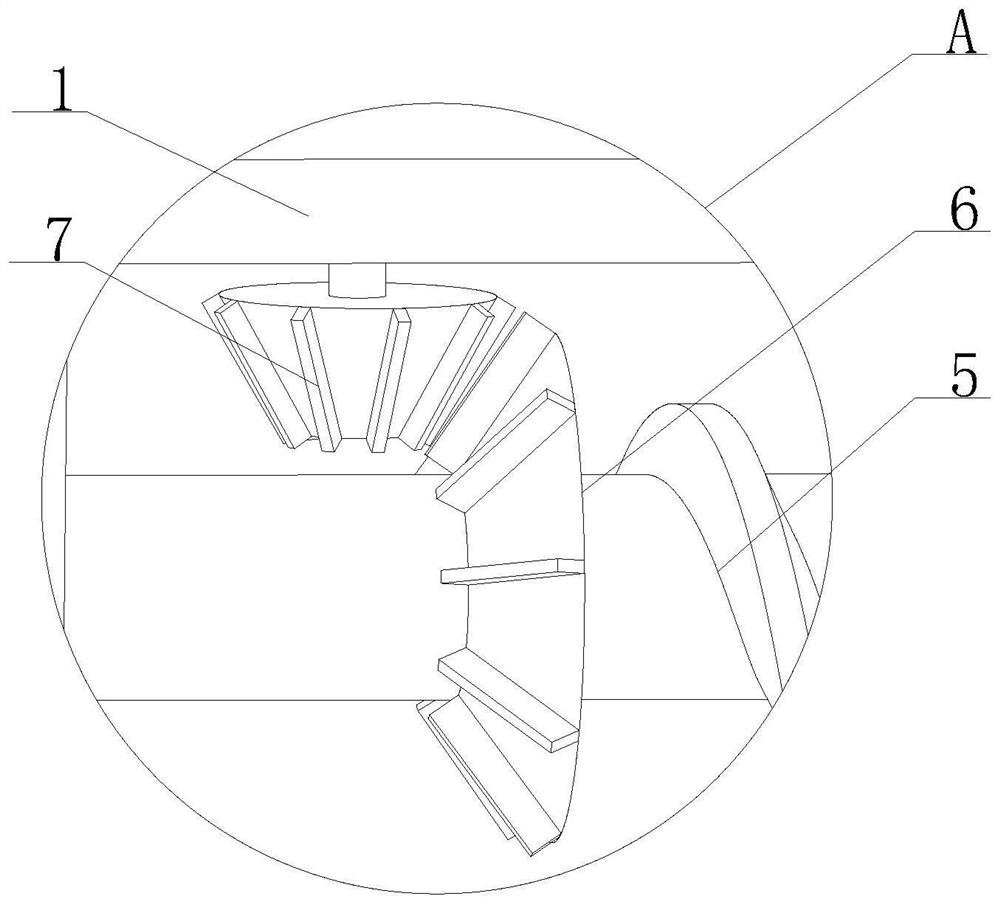

Controllable microwave drying water paint coated furniture equipment

PendingCN113441314AAvoid material damageExquisite designSpray boothsCleaning processes and apparatusElectric machineryEngineering

The invention discloses controllable microwave drying water paint coated furniture equipment, and relates to the technical field of coating furniture. The controllable microwave drying water paint coated furniture equipment comprises a coating equipment body and a microwave transmitting device, a cabinet door is rotatably connected with the front end face of the coating equipment body, the microwave transmitting device is arranged at the bottom of an inner cavity of the coating equipment body, a supporting plate is fixedly connected to the upper end face of the microwave transmitting device, sensing systems are evenly arranged on the upper end face of the supporting plate, and a motor is fixedly connected to the left side of the upper end face of the coating equipment body. Through combination of a temperature sensor, the microwave transmitting device and a controller, control over the internal temperature of the coating equipment body is facilitated; through combined arrangement of a motor, a first bevel gear, a second bevel gear, a threaded rod, an electric telescopic rod and a hair sticking device, the surface of a furniture board is brushed; and through the combined arrangement of springs, C-shaped blocks, bolts and rubber pads, the coated furniture board can be clamped, and the situation that the furniture board are collided and scratched is avoided.

Owner:吴敬明

Cable copper nose punching equipment with automatic feeding and blanking

InactiveCN112054366AAvoid material damageIncrease productivityContact member manufacturingElectric machineryStructural engineering

The invention discloses a cable copper nose punching equipment with automatic feeding and blanking. The equipment comprises a bottom machine box, a feeding device is installed on the right side of theupper surface of the bottom machine box, a clamping device is installed below the perpendicular line of the feeding device on the right side of an inner cavity of the bottom machine box, a single-column hydraulic cylinder is installed on the left side of the upper surface of the bottom machine box, a telescopic rod is arranged in the bottom center line of a punch, and a stabilizing device is arranged in the middle of the right side surface of a die base. The feeding device and a feeding bin are arranged on the right side surface of the bottom machine box. Through the arrangement of the feeding bin, copper noses can be conveniently stored into the feeding device; and then through the arrangement of a conveying disc and a control motor, the copper noses falling onto the conveying disc can conveniently fall into the bottom machine box in a rotating mode, material damage caused by misoperation during manual feeding is avoided, and therefore an automatic structure can be easily formed, andthe production efficiency is improved.

Owner:重庆数智源智能装备科技有限公司

Safety extension base and control method thereof

ActiveUS8923992B2Avoid material damageSafety arrangmentsComputer controlMain processing unitCommunication unit

A safety-extension base connected to a main base and a control method thereof are disclosed, the base includes a communication unit, a system state monitoring unit, a module control unit, a memory unit, a state conversion unit and a safety-processing unit. The communication unit performs data communication with the main base. The system state monitoring unit monitors a state of the PLC system. The module control unit controls a general operation of the safety-extension base and outputs different cases of control signals. The memory unit stores the data transmitted from the main base and a program and information. The state conversion unit converts the state of the safety-extension base into the normal state or safety state. The safety-processing unit performs a control of the safety-extension base.

Owner:LS IND SYETEMS CO LTD

Sintering furnace for components consisting of a sintering material, in particular for dental components, and a method for sintering such components

ActiveUS9958207B2Reduces the hazard of excessively fast coolingAvoid material damageFurnace typesControl devices for furnacesMetallurgyComputer program

Owner:SIRONA DENTAL SYSTEMS

Cutting machine for celluloid plate

PendingCN113977648AAvoid safety hazardsAvoid material damageMetal working apparatusHydraulic ramWorm drive

The invention provides a cutting machine for a celluloid plate. The cutting machine comprises a device shell, wherein a first electric sliding rail is transversely arranged at the top of the inner wall of the device shell, a first moving seat is arranged on the lower surface of a sliding part driven by the first electric sliding rail, a second electric sliding rail is transversely arranged on the lower surface of the first moving seat, and a hydraulic oil cylinder is arranged on the lower surface of a driving sliding part of the second electric sliding rail. According to the cutting machine for the celluloid plate, by arranging a worm gear on the surface of a rotating rod, when the rotating rod drives the worm gear to rotate, the worm gear is engaged with the first worm, and the first worm drives a moving plate to move through threads so as to fix materials, so that the problems that potential safety hazards are easily caused by manual fixing, and the cutting precision is affected due to shaking of the materials during cutting are solved.

Owner:九江赛璐珞实业有限公司

Steel ball automatic buffer receiving device

The invention discloses an automatic steel ball buffering and receiving device which comprises a buffering blanking device and a lifting receiver. The buffering blanking device comprises a feeding pipe and a blanking pipe. The blanking pipe is internally provided with inclined buffering plates for enabling steel balls to fall in a zigzag track mode and arranged in a staggered mode. The lifting receiver comprises a ball receiving frame, an air cylinder, a controller and a position sensor. Due to the fact that the steel balls are blocked by the inclined buffering plates in the blanking pipe, the steel balls are made to fall in the zigzag track mode, and the falling speed of the steel balls is greatly reduced, so that the problem the steel balls are collided and damaged in the blanking process can be avoided; the position sensor is used to detect the height position of the steel balls in the ball receiving frame, when the position sensor detects that the steel ball position is lower than the set position, the ball receiving frame is lifted to shorten the steel ball falling height, so that the problem that the steel balls are collided and damaged can be avoided; when the position sensor detects that the steel ball position is higher than the set position, the ball receiving frame is lowered, the steel ball falling height is increased, and the problem that a steel ball discharging opening is blocked can be avoided.

Owner:TSUBAKI HOOVER (CHONGQING) CORP LTD

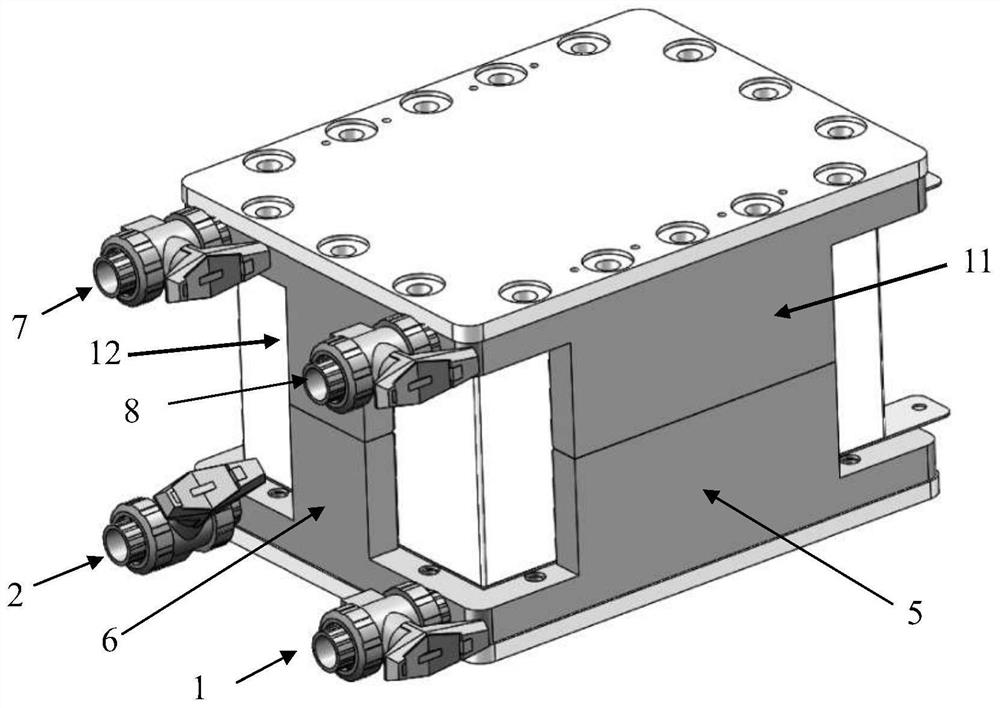

Flow battery stack liquid guide plate structure and application

PendingCN114520361AImprove stack reliabilityAvoid material damageRegenerative fuel cellsElectrical batteryStructural engineering

The invention relates to a flow cell stack liquid guide plate structure, which is characterized in that strip-shaped limiting blocks perpendicular to the surface of a flat plate are respectively arranged at the edges of four sides of the surface of one side of one liquid guide plate of a flow cell stack along the side length direction, and the other liquid guide plate is provided with corresponding strip-shaped limiting blocks and / or strip-shaped limiting blocks staggered with the strip-shaped limiting blocks on the liquid guide plate. And a corresponding through hole is formed in the corresponding limiting block and penetrates through the positioning block and the liquid guide plate. In the process of assembling and pressing the galvanic pile, the limiting block can well limit the transverse displacement of the electrode frame, so that the pulling force on the material caused by the extrusion offset of the electrode frame is prevented, the sealing and positioning requirements are better met, and the reliability and the assembly success rate of the galvanic pile are improved. In addition, the limiting block limits the pressing thickness of the galvanic pile, and material damage caused by overpressure is avoided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com